US $19.88

| Condition | New other (see details)

:

A new, unused item with absolutely no signs of wear. The item may be missing the original packaging, or in the original packaging but not sealed. The item may be a factory second or a new, unused item with defects. See the seller’s listing for full details and description of any imperfections.

|

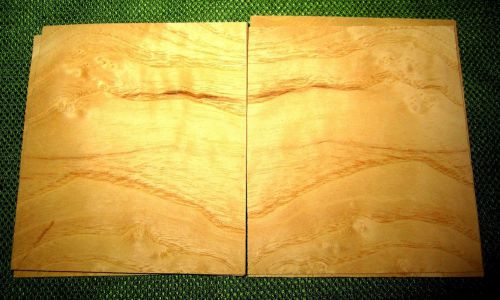

| Seller Notes | “Need wood? I'm the man....” |

Directions

Similar products from Industrial Wood & Interline

South American rosewood veneer 12"x40"

Cherry wood veneer 11" x 27" <Jewelry Box> 4494-25

Cherry wood veneer 11" x 44" <Jewelry Box> 4494-26

2 Bookmatched leafs Ash Burl @ 4.5 x 4 Craft wood Veneer (v1179)

6 Bookmatched leafs Wormy White Ash @ 6-3/8 x 4 Craft wood Veneer (v1135)

9 Bookmatched leafs White Ash Burl @ 4-5/8 x 3-7/8 Craft wood Veneer (v1139)

8 Bookmatched leafs White Ash @ 4.25 x 3.5 Craft wood Veneer (v1130)

7 Bookmatched leafs White Ash @ 5 x 3.5 Craft wood Veneer (v1126)

22 Bookmatched leafs White Ash @ 5 x 3.5 Craft wood Veneer (v1108)

5 leafs Wormy Ash @ 6 x 4-7/8 Craft wood Veneer (v1104)

20 leafs of Quilted Olive Ash @ 23 x 2-7/8 wood Veneer (#v1091)

Cherry wood veneer 6.5" x 51" <Jewelry Box> 4494-28

'Killer' Ropey Cherry wood veneer 7" x 19" <Jewelry Box> 4494-30

Cherry wood veneer 6.5" x 51" <Jewelry Box> 4494-29

'Killer' Ropey Cherry wood veneer 6" x 35.5" <Jewelry Box> 4494-31

Cherry wood veneer 8.25" x 50" <Jewelry Box> 4494-27

Cherry wood veneer 8" x 33" <Jewelry Box> 4494-33

Cherry wood veneer 5.5" x 37" <Jewelry Box> 4494-34

Cherry wood veneer 5" x 36" <Jewelry Box> 4494-32

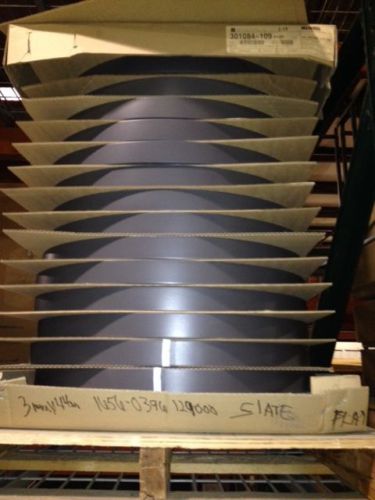

PVC Edge Banding WilsonArt Slate 3MM x 44MM FLAT

People who viewed this item also vieved

RARE VINTAGE ZUCKERMANN HRZ HEAVY THREE SIDE PLANER MOULDER BROCHURE VIENNA

Saw Dial Removed From Craftsman 10" Radial Saw Model 113.29411

Tube Assembly Column Removed From Craftsman 10" Radial Saw Model 113.29411

Onsrud -77-102 1/8" x 1-1/2" of Cut, 2 Flute, Upcut Spiral Router bit

Onsrud 77-102 - 1/8 Inch x 1-1/2 Inch Length 2 Flute, Upcut Spiral Router Bit

New Diablo FB-015 2in Forstner Bit with 3/8in shank DJ723

Lot 2 each 3/8 16 T Knobs 2.5" wide by 1.125" high w/ Through Insert TKI-3/8-X2

Lot 2 each 5/16 18 T Knobs 2" wide by 1.125" high w/ Through Insert TKI-5/16-X2

Bosch RSM418 4-Inch 18T Metal Cutting reciprocating Saw Blades - 5 Pack

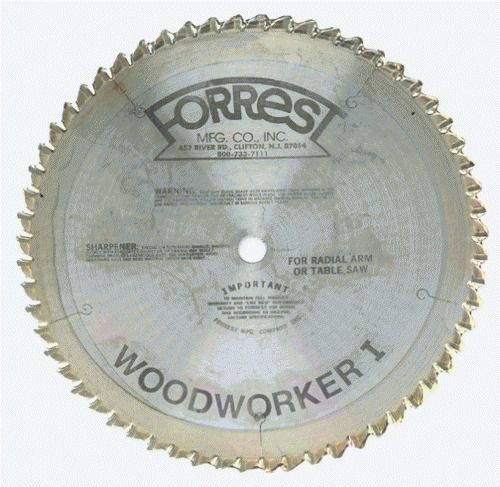

Forrest WW12607125G Woodworker I 12-Inch 60 Tooth 1-Inch Arbor 1/8-Inch Kerf

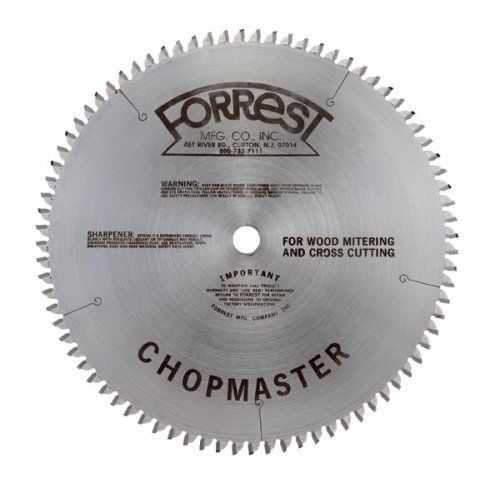

Forrest CM06H406100 Chopmaster 6-1/2-Inch 40 Tooth 5/8-Inch Arbor 3/32-Inch Kerf

MADE IN USA Heavy Duty Metal Marking Steel Punch Tool 3 Lines of text 6mmX 6mm

Irwin Tools 2088600 Self Retracting Safety Knife with Ergonomic NoSlip Handle

Ingersoll-Rand 22040968 Digging Pavement Breaker Chisel

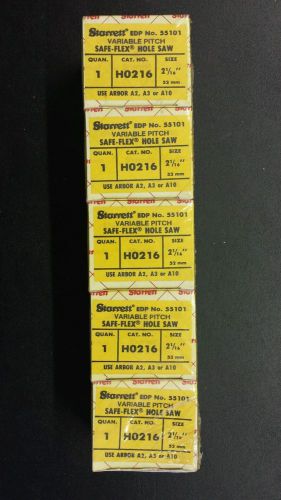

Starrett 2-1/16" 52mm hole saws no.H0216 lot of 5 new in box

GENUINE ORANGE FREEBORN COPE & PATTERN TANTUNG CARBIDE SHAPER CUTTER 3/4 BORE

EARLY LRH # 28 C CONCAVE DOOR EDGE TRIM BOTTOM CARBIDE SHAPER CUTTER 3/4 BORE

29 pc Super Primalloy Maintenance Length Drill Set (1/16 - 1/2) Kimball Midwest

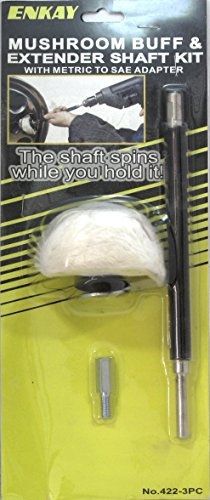

Enkay 422-3PC Extended Bit Holder, 1/4-Inch Shank

Chicago Latrobe Drill Bit Case, 25 Bit Capacity, for Metric Sizes 1 mm to 13 mm

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies