US $125.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

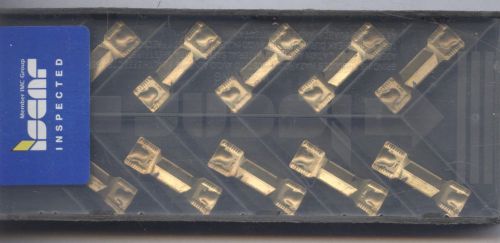

Brand | ISCAR |

| Material | Carbide Inserts | ||

| Model | HM90 APCR 160532R-P | ||

| SOME BOX MAYBE OPENED | INSERTS IS NEW NEVER USED | ||

| MPN | MILLING | ||

| SHIPPING | OFFER COMBINE SHIPPING | ||

| Primary Application(s) | High-Temperature Alloy, Non-Ferrous Material, Stainless Steel, Steel |

Directions

Similar products from Carbide Inserts & Face Mills

SANDVIK R210-14 05 14E-PM 1030 Insert

MITSUBISHI DNMG432SA UC6010 Insert

KYOCERA JOMT100308ER-D PR830 Insert

SANDVIK TNHF 12 04 AN-WL HM Insert

10pcs - FREE SHIPPING - ISCAR HM90 APCR 160505R-P IC 28 10pcs

(10pcs) NG3125L K68 KENNAMETAL Insert

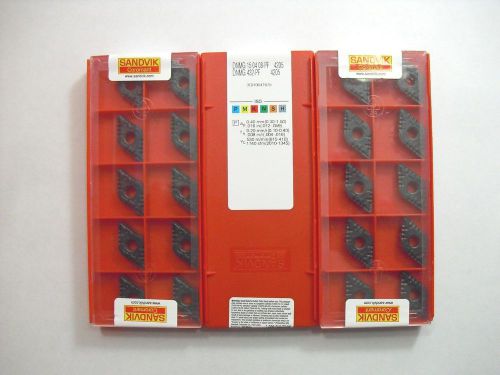

SANDVIK DNMG 15 04 08-PF 4205 Insert

Greenleaf CNGG 431-TF G-920 Insert

SANDVIK TLGP-3062R 1125 Carbide Insert

(10pcs) SECO VNGM 331-MF1 CP200 Carbide Insert

ISCAR GRIP 6005Y IC 508 Inserts for External, I- 10pcs

Set of 3 Harvey Tool Indexable Cutter Inserts. 60031. TPMT-321 C5. With Case

INGERSOLL CARBIDE INSERTS NCHX250600R GRADE IN1030 PACK OF 9

SANDVIK CARBIDE INSERTS WCMX 05 03 08 R-53 GRADE H13A PACK OF 4

KENNAMETAL CARBIDE INSERTS MWT-4 KC950 PACK OF 8

SECO CARBIDE INSERTS APFT 1604PDTR -D15 PACK OF 10 GRADE S10M

SANDVIK CARBIDE INSERTS LCMX 04 03 08 -53 GRADE 4025 PACK OF 9

WALTER CARBIDE INSERTS P26339R14 SEALED PACK OF 10 GRADE WXP45

People who viewed this item also vieved

Single End Mill" ONYX-MSC" 5/8x5/8 x 3 1/8"I"C 4 FLT

Single End Mill unknown Mfg, four FLT, 1", 4" overall

Milling Machine Gear Cutter Brown & Sharpe No. 2-5 DP Bevel for 1-1/4" shaft

(3) Scientific Cutting Tools, Single Point Threading Tools, 1/4" shank,

Di-Acro D half round punch and die set .250" x .156" clearance .0075 diacro

6mm x .75 Metric Right hand Die M6 x 0.75mm Pitch

Chucking Reamer .7340 Diameter HSS

Briggs Motorsports Carburetor Reamer with Pilot

CeramTec TCUN 160408 T02020 SL500

2013 COSEN MODEL AH 250R Automatic (ROLLER TYPE) HORIZONTAL BAND SAW C260-NC

LOT OF 14 HSS SLITTING & SLOTTING BLADES 2-3/4" TO 4" WITH 1" BORE & 1 ARBOR

Carbide Bur Engine Porting Tool Tungsten Cutting Burr Cylinder Shape Double Cut

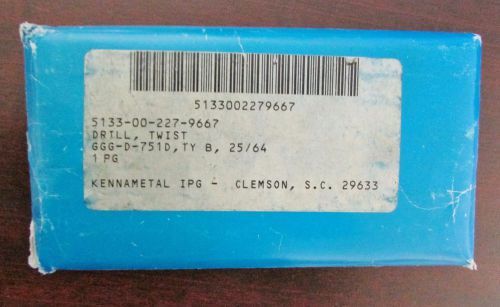

Pack of (6) KENNAMETAL 5133 00 227 9667 25/64 Carbide Drill Bit GGG D 751D TY B

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies