US $69

Directions

Similar products from Stepper Motor Driver Boards & Modules

dual vnh2sp30 stepper motor driver module 30a monster moto shield replace l298n

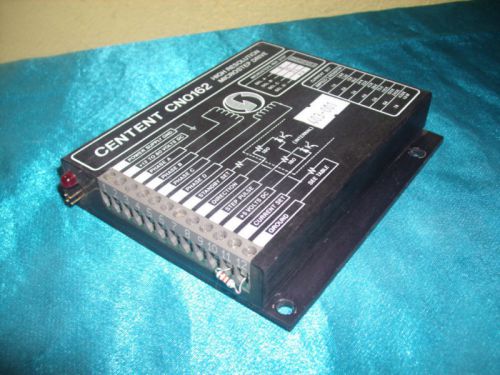

Centent CN0162 High Resolution Microstep Drive

Oriental Motor PK543-A-C8 PK543AC8 5PH Stepping Motor

Shimpo MCDISPI Motion Controller 5 Phase Stepping Drive

Vexta STP-5P533 PH533 Stepping Drive

Oriental Motor PK244-04A PK24404A 2PH Stepping Motor

Oriental Motor D107-A3 D107A3 5 Phase Driver

2-Phase Step motor driver 1PC DQ542MA 4.2A /18-50V to Nema23 CNC Digital

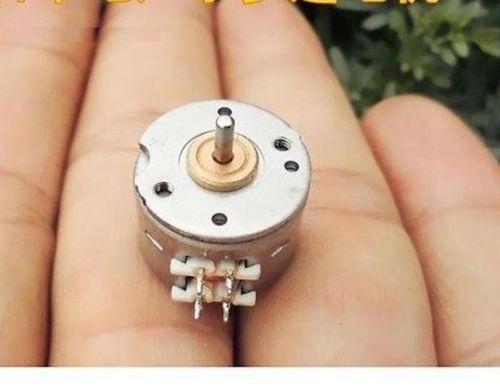

2pcs New two-phase four-wire 15MM stepper motor ACM

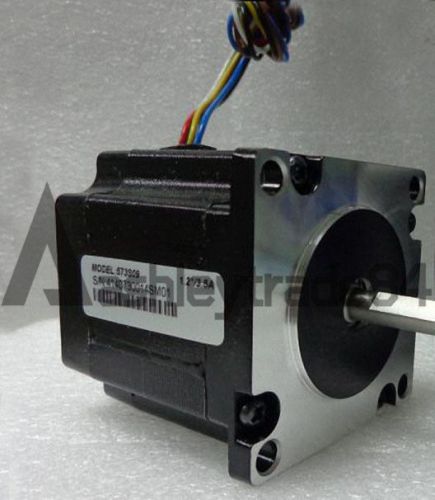

Leadshine 573S09 3-phase Hybrid Step Motor

Wantai 1Axis NEMA34 Stepper Motor 1090OZ-IN,5.6A&driver DQ860MA 7.8A CNCKIT

NEW Kinco HMI MT4403TE 8" 2 month warranty

Superior Electric SLO-SYN 2000 SS2000MD7-RC-101

Parker XL-50I XL-SERIES MINI STEPPER DRIVES Controller

IBT-2 43A BTS7960 High Power Intelligent H-bridge Vehicle Motor Drive Module

2-Phase 4-Wire Ultra-micro Stepper Motor 3.9MM Precision Screw F Digital Product

6MM Two-phase Four-wire Miniature Micro Stepper Motor with Black Plastic Gear

15MM Two-Phase Four-Wire Gray Stepper Motor For Car Boat Electric Product DIY

Leadshine 2 Phase HBS86H Hybird servo Drive+86HS40-EC-1000 Stepper Motor+3M Cord

People who viewed this item also vieved

DANAHER MOTION EZ-GO RXV CONTROLLER - 83A21102A

Used FANUC A06B-6140-H037 Tested 3m Warranty

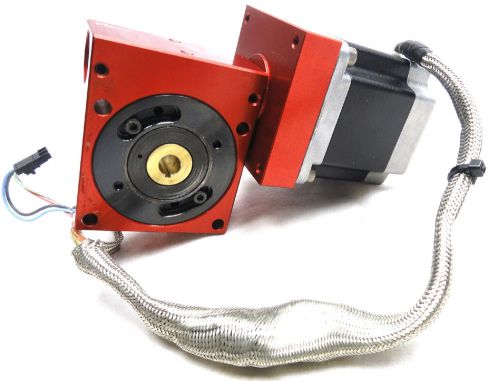

Precision Worm Gear Reducer Stepper Motor | 1 Rino 0ND03454 1 Vexta C014S-9212K

CUTLER HAMMER RELAY MOTOR CIRCUIT PROTECTOR IQ DP-4000 WITH 3 PHASE POWER MODULE

Honeywell UV detector mini-peeper C7027A 1049 NEW..!

Honeywell Dual potentiometer Q688 1005 For 2 series 90 Modutrol Motor

CHALLENGER AC LIGHTING CONTACTOR 4104CU32L01, Size 3, 100 AMPS, MODEL M S914216

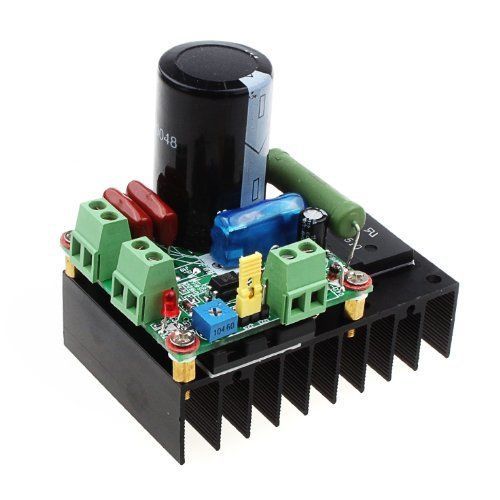

KEDSUMA® 12V 24V 48V 110V DC Motor Speed Driver Controller PWM MACH3 Spindle

KB Electronics 8811012 Solid State Variable Speed AC Electric Motor Control, 5.0

Tsubaki NO. 40 (TW) RIV. 10 FT. Roller Chain

New 9-50V 40A DC Motor Speed Control PWM HHO RC Controller 12V 24V 48V 2000W MAX

Low Voltage DC 12V 2A Motor Speed Controller PWM 1803B

New DelRoyd Single Worm Gear Speed Reducer 570-999 40:1 02D66980 Nutall Gear

70A 10-63V 12V 24V 48V current limited DC motor PWM speed controller waterproof

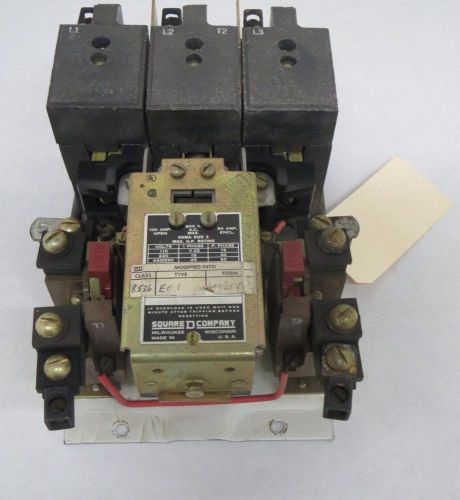

SQUARE D 8536 E01 SIZE 3 50HP 100A AMP MOTOR STARTER B312975

NEW SQUARE D 8536SCG3S SIZE 1 120V-AC 10HP 27A AMP MOTOR STARTER D362542

NEW FUJI ELECTRIC MAGNETIC SWITCH SW-4-0/2E 4NWOQO4T10K 9-13 A 440-480 V

Allen-Bradley 140-L2,SERIES D Terminal Link, 690v 63a,3 Phase

Cutler Hammer CM25BP Base Mounted 4-th Pole for Rotary Switch, 25a

Cutler Hammer CMAC Auxiliary Contact Block, 15a 120vac,1NO/1NC

Telemecanique GV2-G354 Busbar for 3 Starters, 690v 63a

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies