US $15.00

Directions

Similar products from Heat Pressure Equipment

NEENAH TRANSFER PAPER JET OPAQUE II 25 SHEETS FOR DARK FABRICS

15x15 Heat Transfer Press,13" Vinyl Cutter Plotter,Printer,Cartridges,PU Vinyl

New 8in1Heat Transfer Press,Epson Printer C88,CISS,T-shirts,Mugs,Hats,Plates,DIY

24" 1000g Vinyl Cutter Plotter, Sign,Vinyl,Decal,PU Vinyl,T-shirt Heat Transfer

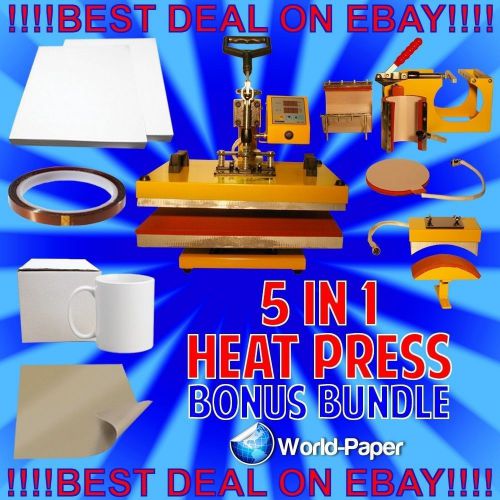

New Digital Pro Heat Transfer Press Machine 5 in 1 T-shirt Mug Hat Plate Cap

16X20 HEAT PRESS DURABLE STEEL T-SHIRT SUBLIMATION CLAMSHELL DESIGN SPECIAL BUY

16X20 HEAT PRESS THICKER HEATING BOARD 16 X 20 PRINTING TEMPERATURE CONTROL

16X20 HEAT PRESS DIGITAL LCD TIMER DIGITAL TRANSFER PRESSING MACHINE WHOLESALE

16X20 HEAT PRESS ADJUSTABLE PRESSURE T-SHIRT SUBLIMATION CLAMSHELL DESIGN GREAT

1 yard T-shirt Glow in Dark Heat Transfer Vinyl For Heat Press

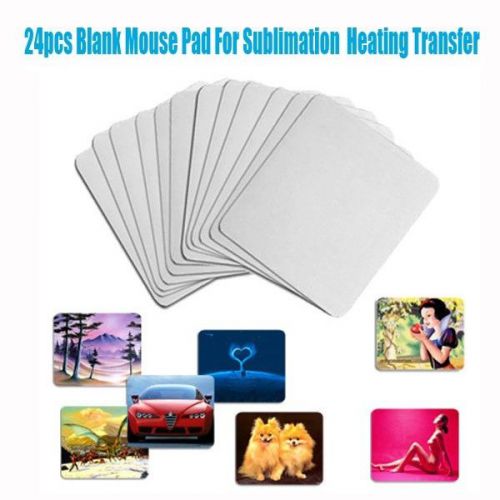

20 pcs Mouse Pad Heating Transfer Sublimation Blank Press Printing DIY Images

New 6PCS Blank PAD MINI Cover Case Sublimation Heating Transfer Ink Printing

15x15 Heat Press,Epson Printer, CISS Cartridge, Bulk Ink,Tshirt Transfer Package

Techni-Print EZP Heat Transfer Paper 11" x 17" 50 sheets

UKPress MUG Heat Press MP160 Latte Durham Sublimation Printing Heat Transfer

50 sheets 8 1/2" x 11" Heat Press Transfer Paper Light

5IN1 Multi Heat Press Mug Plate Cap Hat T-shirt Art Sublimation Transfer Machine

IMAGE CLIP Koncert T’s Heat Transfer Paper 8.5X11 10

T-shirt Inkjet Dark Iron On Transfer Paper. 100 Pack.

People who viewed this item also vieved

Goldfinch Pansy Bird HEAT PRESS TRANSFER PRINT for T Shirt Sweatshirt Bag 212c

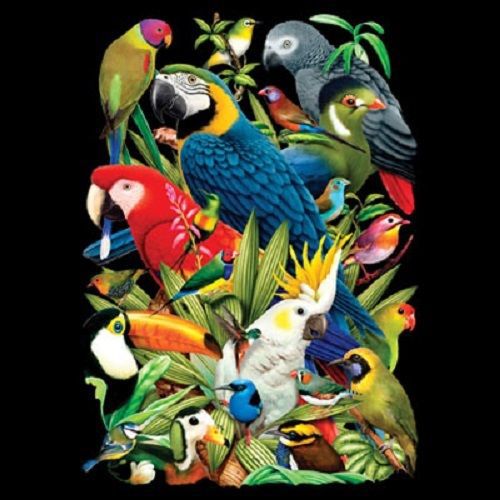

Avian Bird Parrot HEAT PRESS TRANSFER PRINT for T Shirt Sweatshirt Fabric 210c

Tulip StriFloral HEAT PRESS TRANSFER for T Shirt Tote Bag Sweatshirt Fabric 799a

Chillaxin Frog HEAT PRESS TRANSFER for T Shirt Tote Sweatshirt Quilt Fabric 259e

Big Shark Face HEAT PRESS TRANSFER for T Shirt Sweatshirt Quilt Fabric 251o

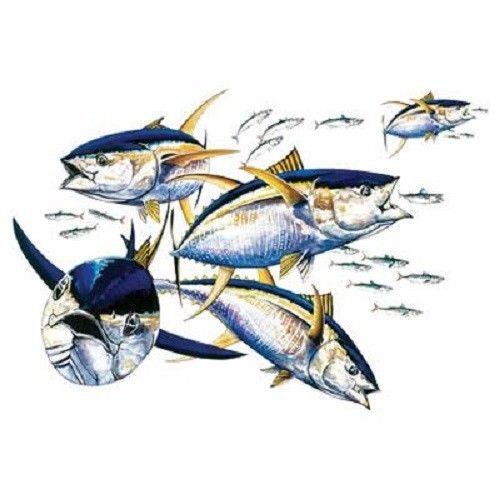

Yellow Fin Tuna HEAT PRESS TRANSFER for T Shirt Sweatshirt Quilt Fabric 247oo

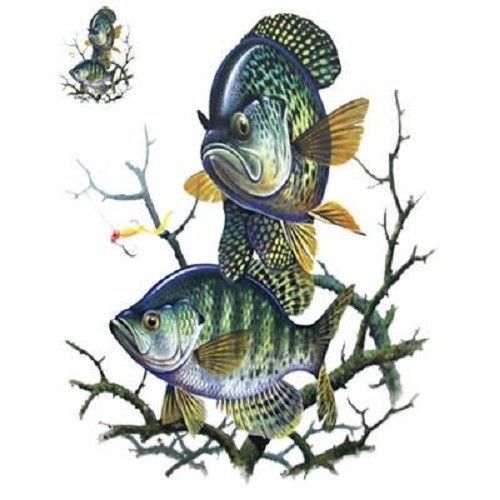

Crappie Fish HEAT PRESS TRANSFER for T Shirt Bag Sweatshirt Quilt Fabric 247o

Hamada RS34LSII printing press

4" x 18" Sublimation Aluminum Street Sign Blanks .042" Thick- $2.75 ea

2" Round Aluminum Dye Sublimation Key Chain Blank-Lot of 50 with Silencer

SPECAIL OFFER Dye Sublimation Dog Tag Blanks & Black Silencer- Lot of 50PCs

6" x 12" Sublimation Aluminum Street Sign Blanks .042" Thick- $2.40 ea

.042" Thick 12" x 18" Aluminum Sublimation Sign Blanks, $5.95 each/10PCs

SOFSTRETCH INKJET IRON ON HEAT TRANSFER PAPER NEENAH JET PRO SS 8.5 X 11" 25 PK

SOFSTRETCH INKJET IRON ON HEAT TRANSFER PAPER NEENAH JET PRO SS 8.5 X 11" 50 PK

30 ea.T-Shirt Inkjet Iron On Heat Transfer paper 8.5" x 11" pack of 10 sheets x3

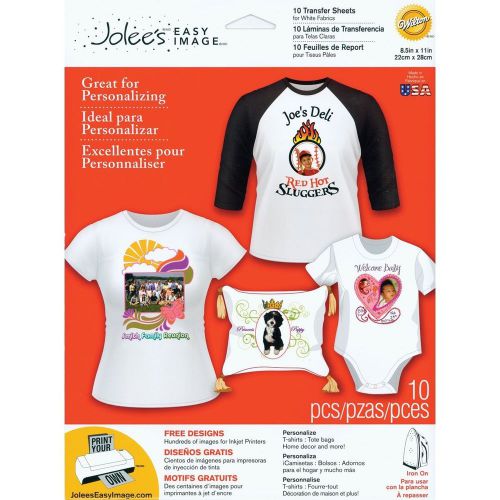

Jolee's Easy Image Iron-on Transfer Sheets, White Fabrics - 5 Sheets

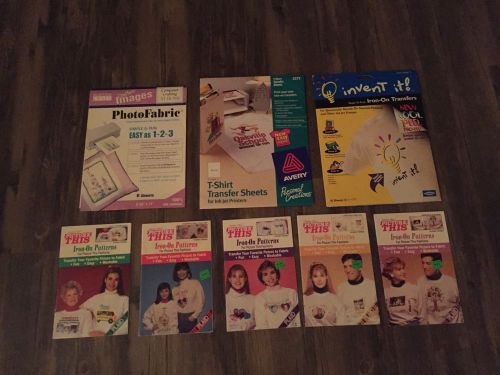

PHOTO FABRIC TRANSFER SHEETS +PICTURE THIS PICTURE TO FABRIC IRON-ON PATTERNS

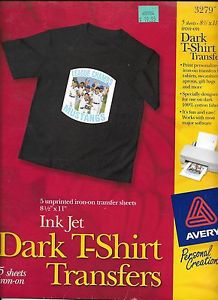

Avery DARK Iron-on Transfers Pk of 5

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies