US $80

Directions

Similar products from Carbide Inserts & Face Mills

KENNAMETAL CARBIDE INSERTS DNMM-443-M (8 PCS)

VALENITE NCBS-3-050 CARBIDE CHIPBREAKERS (11 PCS)

VALENITE SNEA-642 (SNMA) CBN INSERTS (1 PC)

KENNAMETAL CARBIDE INSERTS TNMM-434 (10 PCS)

VALENITE NCBSR-4A-050 CARBIDE CHIPBREAKERS (10 PCS)

*30pcs * FREE SHIPPING * SANDVIK R390-11T316M-PM 1025 30pcs* LOT OF *

MITSUBISHI UPE-122-C CARBIDE MILLING INSERTS (5 PCS)

KOMET W29-24030.046425 UNISIX CARBIDE INSERTS (10 PCS)

Iscar S9OMT Carbide Inserts Great Deal!

NEW (2 Inserts) 1- 1/4" AMEC #2 T-A Cobalt TiN Spade FB Inserts (P 543)

(2 Inserts) 17.5mm AMEC #0 GEN2 T-A AM200 Spade Inserts (P 549)

Kennametal GS32R GS125R KC720 Carbide Insert (10pcs) ../

BRAND NEW ph HORN FACE Grooving, Turning holder with 4 Grooving inserts kit

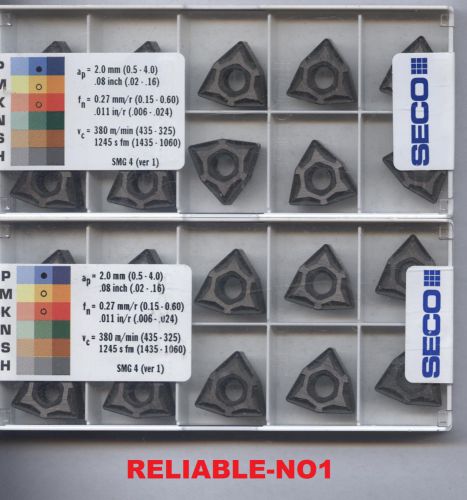

*SHIPPING IS FREE * 40pcs * SECO WNMG 080408-M3(WNMG432-M3) TP 2500 40pcs

GE VNGA-333 BZN6000 CBN Turning insert for Hardened Steel and Cast Iron

NTK DNGA434 carbide inserts .. (ceramic)..*Free shipping*

SECO # 42944 carbide parallelogram milling insert

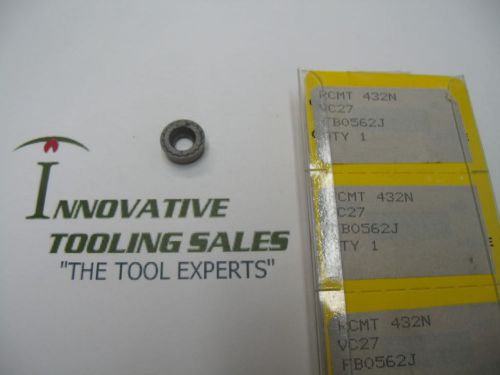

RCMT 432N Carbide Inserts Grade VC27 Valenite 5 Pcs

19 KENNAMETAL SERRATED 1/2" INSERTS SNMV-43. KC850

40 ISCAR ADKT 150524R-HM IC928 Carbide Inserts

People who viewed this item also vieved

DUMONT Broach 3/8-D 22213 NEW!! MADE IN USA!!

Cogsdill Burnising Tool BT1438 "7" 2MT 3/4" Diameter

CBN (Cubic Boron Nitride), SGN1 NR-30375 R Grooving Insert .0375 Radius NIB

CBN (Cubic Boron Nitride), SGN1 NR-3094 R Grooving Insert .094 Radius NIB

1 NEW CHAMPION-UK END MILL 3/8" DIA. 4 FLUTE

13 NEW 3 MM SHANK CARBIDE END MILLS. 4 FLUTE. BALL. USA MADE. (F567)

KEO 610 STRAIGHT TOOTH WOODRUFF KEYSEAT CUTTER 1-1/4" X 3/16"

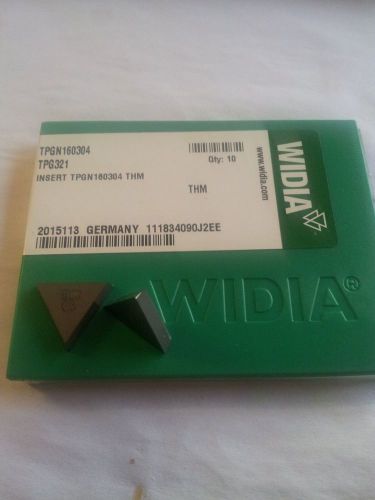

Widia insert TPGN160304, TPG321, 2015113 (10 inserts)

VINTAGE MUTUAL ADJUSTABLE HAND PUNCH IN ORIGINAL BOX

MACHINIST LATHE MILL Lot of Center Punches Transfer Punches in Stand

"R.R.T." Carbide Tipped Chucking Reamer.3745"-Four Flute

"R.R.T. Chucking Reamer Carbide Tipped 1/2"--Six Flute

JEWELER'S SAW 3" x .028 x 1" W/220T J5302810000

MORSE BANDSAW BLADES 3/4” 32 18W HB 7' 9” LENGTH 4WU46 (3 PCS)

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies