US $1800

Directions

Similar products from Other Measuring & Monitoring Tools

Starrett No.196 Dial Indicator w/ back Plunger New, or gently used (931-3-S)

Gem Instrument Indicator Bar Clamp 212 (931-3-T)

Starrett No. S579-G Set of 4 Telescoping Gauges 1/2-3/4 (931-3-U)

SIX !! Cle-Forge 9.75mm x 7-3/8" Hss Drill Bits

Starrett 1/4" Punch Set and Center Finder (931-3-Y)

Machinist Grab Bag! Angle Finder & Surface Gauge (931-3-Z)

Starrett No. 172 Feeder Gauge 1003. .008 .010 .015 (931-3-Z1)

Starrett No. 610 N 12" Hook Rule (931-3-Z2)

Starrett No. 67-A Scriber (931-3-Z3)

STARRETT MACHINIST'S HIGH SPEED INDICATOR

Starrett 98-8 Precision Machinist 8" Level, no rust & in excellent condition.

VINTAGE DOALL OPTICAL FLAT, 2", .000005, In Velvet Lined Box, FREE SHIPPING NR!

12 Inch Vertical digital Scale

Vintage Moore & Wright, Sheffield, England, Engineering Inclinometer Level, 7" L

18 inch 360 Position Heavy-Duty Style B Ultradex Angular Indexing Table

Auto Collimator; Hilger & Watts No. 127506 (CTAM #8246)

Clinometer; MC; Hilger & Watts 117889 (CTAM #8245)

STL X GO LONG REV GAGE 0.1646 X 2-1/2 PN: 171204110

People who viewed this item also vieved

L.S.S LS STARRETT INSIDE CALIPER

LS STARRETT HERMAPHRODITE CALIPER

BROWN & SHARPE BESTEST .0005 W/ SWIVEL DOVETAIL CLAMP

SCHERR TUMICO DIAL INDICATOR .001 1/2" TRAVEL

Starrett Depth Gage No. 237 with Rule No. 61 ON

COLMAN GYZJ 934-1 BARCOL HARDNESS TESTER

MITUTOYO ANVIL6.5MM 0.2559" FOR 526 SERIES SPLIT BALL DIAL BORE GAGE P# 050649

++ Pratt Whitney Precision End Measures-Inside Micrometers

Double Sides Metric 15cm 6inches Stainless Steel Straight Ruler

2 in 1 30cm 20cm Double Sides Students Metric Straight Ruler Silver Tone

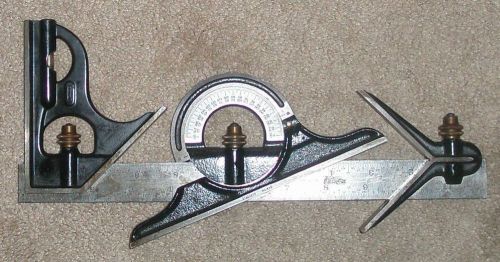

Vintage 4-Piece Combination Square - 3 Starrett Heads on Lufkin 4R Blade

Starrett Combination Square & Satin Chrome 12" Blade, 4R 1224, Xlnt used

2 MAGNETIC HOLDERS & FINE ADJUST ATTACHMENTS machinist tools *G

Rod For Magnetic Base Indicator Holder 1/4" Diameter 6" Length 657x

L.S. Starrett No. 183 Steel Protractor USA Precision Tool

MACHINIST LATHE MILL Machinist 12" Combination Ruler Protractor Square Level

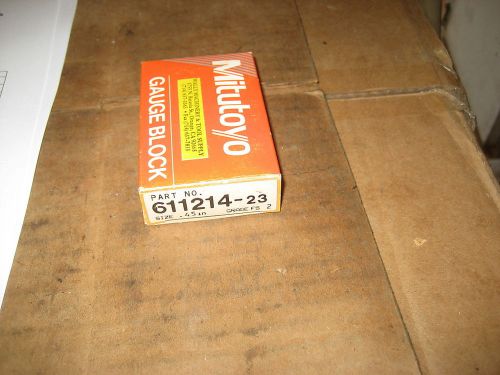

MITUTOYO 611214-23 .45 GRD2 GAGE BLOCK (LW0713/0717-1)

MITUTOYO 611616 GRD2 6.0MM GAGE BLOCK (LW0715-1)

GRANITE PLATE 12" x 24" x 4" THICK ZEISS SURFCOM and CONTOURECORD

VINTAGE SURFACE ROUGHNESS COMPARATOR by UNITED STATES RUBBER CO. IN WOODEN BOX.

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies