US $20000

Directions

Similar products from IBM Processing

4/2 way valve Bosch No. 0 810 001 520, Engel used spare parts & molding machines

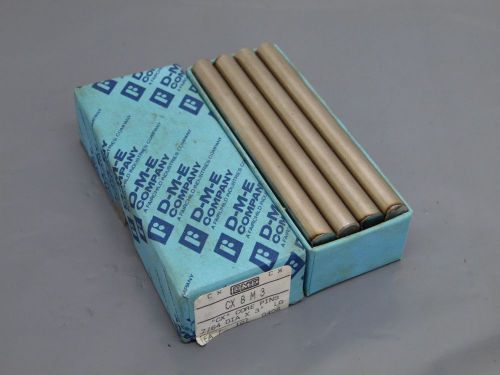

DME cx8m3 7/64 dia x 3" long core pins 12

Pressure sensor for clamping pressure, measuring by tie bar extension, Engel

Displacement unit Novotechnik TLH 225 mm, Engel used spare parts

1989/2009 Trueblood B-200-5 Injection Molding Machine-IMM # 7783663

Displacement unit Novotechnik TLH 450 mm, Engel used spare parts

Central lubrication Willy Vogel type 3-DM7 - MFE5 / KW 3, Engel used spare parts

INEOS N05G-00 Polypropylene Impact Copolymer Injection Molding Grade Pellets

1993 ARBURG 55-TON PLASTIC INJECTION MOLDING MACHINE

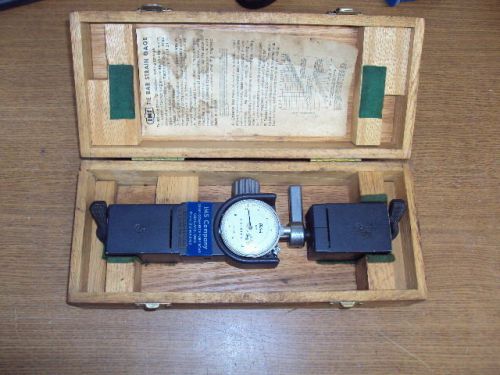

IMS Company Tie-Bar Strain Gage Gauge

4/3 way valve Bosch No. 0 810 091 212, Arburg used spare parts

4/2 way valve Bosch No. 0 810 001 939, Arburg used spare parts

Surveilled way valve SN. 153.179, Bosch No. 0 810 001 904, Arburg spare parts

Cooling water distributor SN. 152.194, Flowmatic 7 circuits, Arburg spare parts

Displacement unit SN. 141.132, Novotechnik LWH 100, Arburg used spare parts

Memory card for Arburg Dialogica SN. 98312, ARB 526 (23)

pressure sensor STS type TM 320 bar u Klockner Ferromatik Milacron

Analogue Digital mixing module B&R 2005, UM161, 3UM161.6

4/2 way valve Bosch No. 0 810 090 106, Krauss Maffei used pare parts

Cat 50 1 1/4 x 24 1/2 mill arbor

People who viewed this item also vieved

Cast in band heater, 1600 watt, 220V Heat only Extruder barrel, 6 1/2" ID Bronze

Cast in band heater, 4100 watt, 230V Heat only Extruder barrel, 5 3/8" ID Bronze

8pcs 0.4mm Copper Extruder Nozzle Print Head for Makerbot MK8 RepRap 3D Printer

3D Printer Kit - 3D Stuffmaker EVOLUTION Gen2 (Black) - Free Shipping

3D Printer Kit - 3D Stuffmaker EVOLUTION Gen2 (transparent) - Free Shipping

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies