US $52

Directions

Similar products from Polishing Wheels

3M(TM) Flexible Grinding Wheel Backup Pad 51045, 4-5/8" Diameter, 7/8" Center

Scotch-Brite(TM) Combi-R Wheel 80679, X-Weight, Roloc Quick-Change Attachment,

3M Scotch-Brite(TM) Combi-R Wheel 80800, X-Weight, Roloc Quick-Change

3M Scotch-Brite(TM) Combi-R Wheel 80802, X-Weight, Roloc Quick-Change

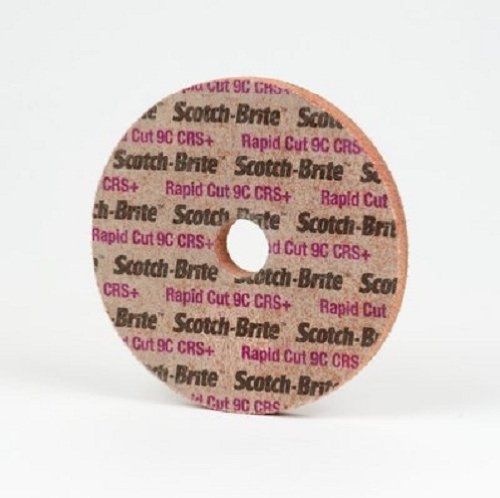

3M Scotch-Brite(TM) Rapid Cut Unitized Wheel, Ceramic Aluminum Oxide, 4"

Lincoln Electric KH243 Depressed Center Grinding Wheel, Aluminum Oxide, 12000

1886-1929 GRINDING SHARPENING STONE TREADLE,SCHOLFIELD PAT.CLEVELAND STONE CO.

Norton Abrasives - St. Gobain Norton BlueFire F826P Abrasive Disc, Fiber

3PACK EDCO Pcd Diamond Grinding Blocks Dyma-Sert- BEST QUALITY GUARANTEED W/boxs

SHARS 6 X 1/8" x 1/4 D1A1 DIAMOND WHEEL 1 505-2227 4300 rpm NEW

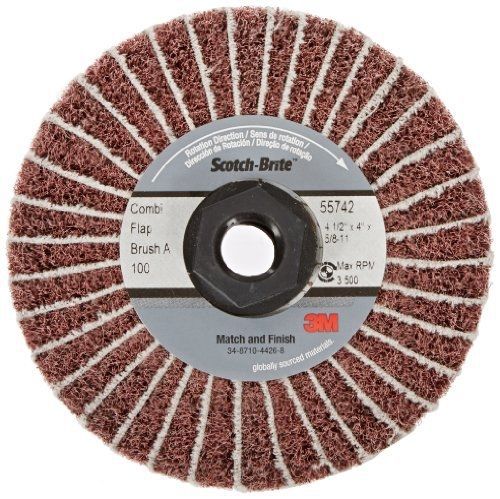

Scotch-Brite(TM) Match and Finish Combi Flap Brush, Aluminum Oxide, 4-1/2"

(4) American Made WALTHAM Grinding Wheels #11A50-LV.

US Forge 751 Mounted Grinding Point A-4 1-1/4-Inch by 1/4-Inch Cone

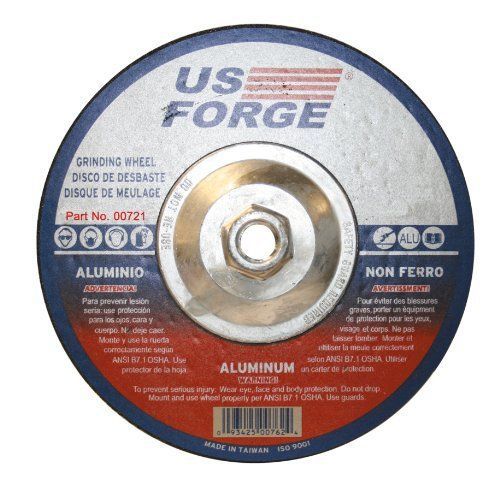

US Forge 721 Grinding Wheel Masonry, 9-Inch by 1/4-Inch by 5/8-Inch-11

Huntington Desmond No 1 Dressing Wheel Urbana Ohio

Assortment - Metal Grinding Wheel / Cutoff / Flap Disc / Wire Wheel / 4 x 5/8

NORTON, SURFACE GRINDING WHEEL, 32A46-H8VBE, 8" X 1/2" X 1 1/4", 46 GRIT

NORTON, SURFACE GRINDING WHEEL, 32A120-K8VBE, 8" X 1/2" X 1 1/4", 120 GRIT

NORTON, PEDESTAL GRINDING WHEEL, C1105288, 8" X 1" X 1", 36 / 46 GRIT

NEW Norton Diamond Wheel SD180-R100B99 - 1/8 Free US Shipping

People who viewed this item also vieved

GATES 8M-2400-21 BELT NNB 1 LOT OF 3

GOODYEAR HI PERFORMANCE PLUS BELT 800 8M 50 NNB

GATES POWERGRIP GT 2 V BELT 9608MGT30 NNB

GATES SUPER HC POWERBAND BELT 3V450 NNB

BLACKSTONE 0815600 12 INCH CARBON STEEL SCRATCH BRUSH LOT OF 12 NEW

JONESWAY #AB040004 STAINLESS STEEL WIRE SCRATCH BRUSH 4 X 16 ROWS USED LOT OF 13

Crimped Wire Wheel Brush 12" Diameter with 1/2" Arbor Metal Working #215905

3M SCOTCH BRITE Finishing Flap Brush 01188 12" x 2" x 5" 2500 RPM (20A)

Norton E2279811 4"X.035"X3/8" Gemini Cutoff Wheel Free

NEW PFERD HORSE ELASTIC 12" X 1/8" X 7/8" GAS SAW STEEL CHOP SAW BLADE GERMANY

ROTOZIP RZMAS2 Zip Mate® Masonry 3-1/2" Cut-Off Wheel 36 Grit 2 Pack

STAHL SUHNER CUT-OFF WHEEL (LOT OF 10) 4.5" STEEL .875 DIA HOLE 3/32W BLADE NEW

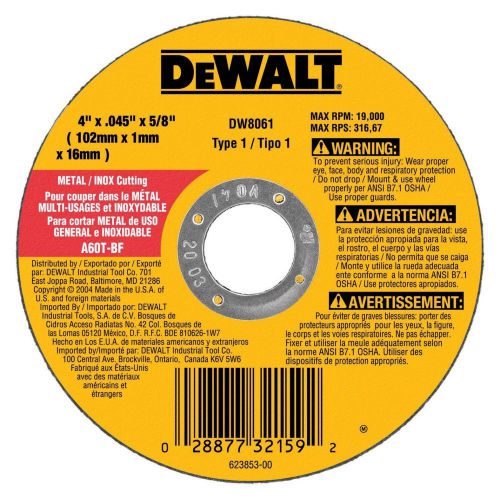

DeWalt DW8061 4-inch x .045-inch x 5/8-inch A60T-BF Abrasive Metal/INOX Cutting

Mitchell Abrasives 46-S Round Abrasive Cord

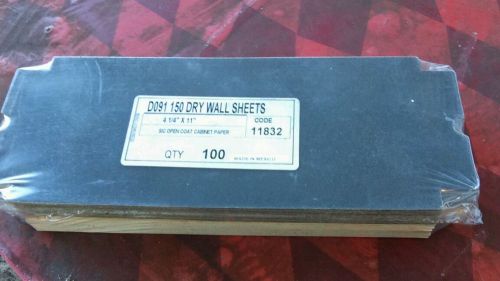

Dry Wall Sand Paper Sheets 4 1/4" x 11" Precut Sheets - Grit - Qty. 100 D091 150

Sandpaper SK11 water-resistant paper mini set 30 pieces 400, # 1000, # 1500

NEW C&A 05539509975 GRINDING WHEEL 6 X 3/4 X 1 IN 60 MEDIUM 5410 RPM B279819

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies