US $19,999.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Modified Item | Yes |

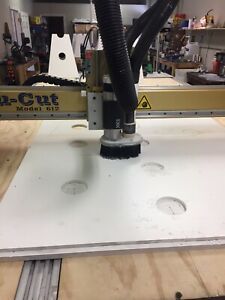

| Effective working travel | (X)51inch 1300mm*(Y)98inch 2500mm*(Z)11.8inch | ||

| Country/Region of Manufacture | United States | ||

| Control unit | Handle control or industrial grade NK-260 | ||

| Custom Bundle | Yes | ||

| MPN | Does Not Apply | ||

| Machine Type | Metal Engraving Machine | ||

| Communication interface | through parallel or usb connection with computer | ||

| Model Year | 2019 | ||

| Repeat accuracy | 0.01mm | ||

| Power Source | Electric | ||

| Frame materials | Steel cnc frame | ||

| Carving Instructions | G code/TAB files/nc file/NCC files | ||

| Spindle speed | 1 ~ 18000/24000 rpm/min (PWM stepless speed regulation) | ||

| Spindle motor | 9kw 11kw 14HP air cooling motor | ||

| Operating Voltage | AC220V 110V/ 380V 400V 50HZ 60HZ | ||

| Principal axis collet | ISO30 | ||

| Modification Description | cnc router machine | ||

| Machine weight | 1200KG | ||

| Brand | Crystal Coast CNC System | ||

| Bundle Listing | Yes | ||

| Bundle Description | crate package | ||

| Shape dimension | 121*86*69inch 3080*2120*1750mm | ||

| Control | CNC | ||

| UPC | Does not apply |

Directions

Similar products from Professional Router Machines

ZUND 5211435 R203-A Router Bit (( LOT OF 10 ))

Upgrade Version CNC 3018 Pro-M Engraving Machine with 3000mW 3W Module 3 Axis 2

DIY Mini USB 1610 Pro CNC Router Desktop Cutter Wood PCB PVC Engraving Mill

VINTAGE STANLEY ELECTRIC ROUTER WITH 1/4" COLLET WOODWORKING TOOL

Porter Cable 513 Lock Mortiser Speedmatic Router Rockwell Part Feed Rod #695843

VINTAGE BLACK AND DECKER 7616 1/4" ROUTER WITH BOX AND WRENCHES WOODWORKING

Cnc Router Machine 4040-Xe, 300W Spindle 3-Axis Engraving Milling Machine For Wo

Plate CNC Touch Probe Metal 3.5*2cm Setting Carving Machine Cord Tools

3 Gecko Drive Raptor Machined Tool Less Mount Heatsinks (Gecko Drive, CNC,)

4 Gecko Drive Raptor Machined Tool Less Mount Heatsinks (Gecko Drive, CNC,)

METABO HPT KM12VCM 2.25 HP Fixed Plunge Base Router Combo Kit M12VC HITACHI

Porter Cable/Rockwell 513 Lock Morteser With Complete Extra Motor And Cutter.

SCT REAMER PILOT PORT TOOL CARBIDE TIPPED CUTTER

10 Pieces CNC Bow Clamp Accessories Milling Engraving Machine New Useful

Acc-Cut X Series Model 612 CNC Router

Gecko G540 CNC 2021 Driver 3YR Warranty & 4 13ft Double Shielded Motor Cables

1/2" x 7/8" x 1/2" Z=3+3 Diamond Router Bit Compression Spiral

People who viewed this item also vieved

POWERMATIC 1150 DRILL PRESS HEAD WORKS GOOD

POWERMATIC 1150 QUILL LOCK WORKS GOOD

TRUCK LOAD OF SOUTH BEND LATHE WITH TAPER ATTACHMENT

Rockwell Delta Wood Lathe complete with stand and tools 6.2-413

Delta Rockwell Wood Lathe Centers

Delta Rockwell Unisaw Dado Throat Plates / Inserts , Lot Of 2

Vintage Delta Rockwell Unisaw, Miter Gauge For 3/8" x 3/4" Slot, Early Type

Ekstrom Carlson Co Industrial Oscillating Edge Belt Sender No. 112

43" Double Wide 3-Phase Belt Sander

ZIMMERMANN SZ-PICCOLO DISC SANDER INSTRUCTIONAL MANUAL W/ WIRING DIAGRAM

Grizzly 12" G5959 Industrial table saw, 5HP 50" max width, in great condition!!!

craftsman professional table saw

Irwin Industrial Tools 2011201 ProTouch 15" 9-Point Coarse Cut Carpenter Saw

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies