US $256.00

Directions

Similar products from Etching

VINTAGE METAL U.S. SOCIAL SECURITY CARD - w/ (2) U.S. AMERICAN FLAGS

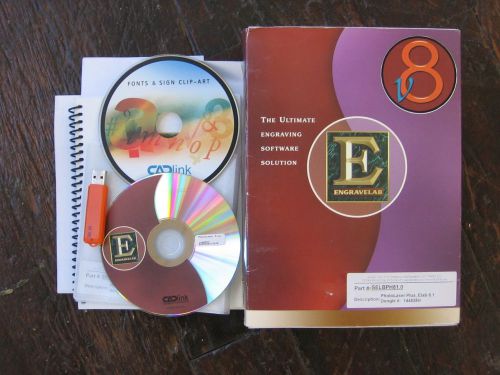

Engravelab Version 8 Rotary Engraver, Software

Vintage Tabletop Engravograph Engraving Machine New Hermes Not Tested GG6033

HERMES GRAVOGRAPH M40 ROTARY ENGRAVER ENGRAVING MACHINE GTM40

roland metaza mpx-80 green caps

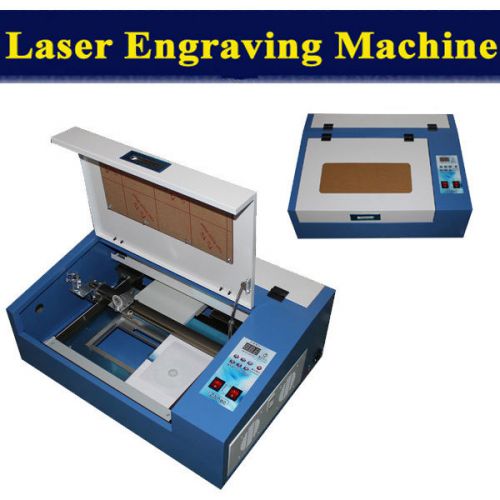

High Precise 40W CO2 Laser Engraving Cutting Machine Engraver Cutter USB Port/CE

Mini 300MW Laser Engraver Engraving Machine Printer Mark Printing Print Wood NEW

300MW Laser Engraver Mini DIY Engraving Machine Printer Mark Printing Print Wood

80W CO2 Laser Engrave Power Supply 110V For Laser Machine

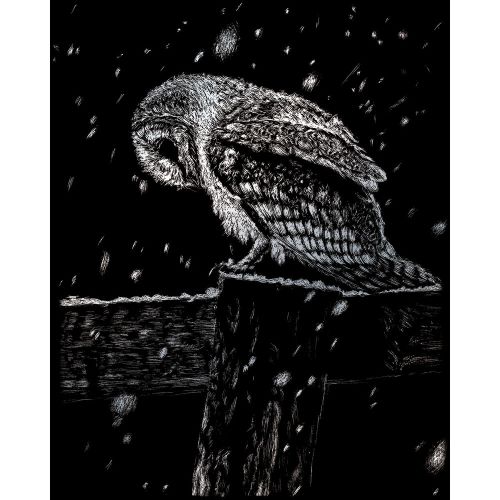

Engraving Tools Brush Silver Foil Art Kit 8X10 Snowfall At Night

Vintage Burgess V-60 Vibro-Marker Electric Engraver USA FREE SHIPPING

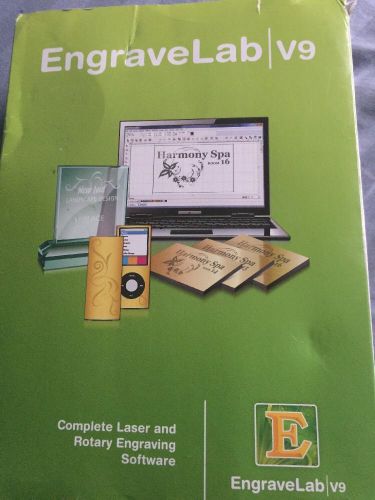

Engravelab Foundation Software US-ENGRAVLAB-F9 , Roland EGX , CADLINK!

CNC ROUTER ENGRAVER ENGRAVING MACHINE PERFECTY VISIBLE CONTROL ROUNTING GREAT

CNC ROUTER ENGRAVER ENGRAVING MACHINE 3 AXIS CARVING VISIBLE CONTROL CUTTER

CNC ROUTER ENGRAVER ENGRAVING MACHINE 3 AXIS CARVING PERFECTY DRILLING WHOLESALE

CNC ROUTER ENGRAVER ENGRAVING MACHINE CUTTING ROUNTING PCB'S CAREFULLY CRAFTED

GRAVOGRAPH NEW HERMES ENGRAVING MACHINE ENGRAVER Engravograph used works great

GCC Venus LaserPro Engraver (similar to Epilog Laser)

2 NEW HERMES engraving machine font letter type stops clamps 1 1/4" engravograph

People who viewed this item also vieved

New Assassins Creed Gaming Logo Mouse Pad Mat Mousepad Hot Gift Game

New Clash Of Clans Gaming Logo Mouse Pad Mat Mousepad Hot Gift Game

New Cummins Dodge Ram Car Racing Logo Mouse Pad Mat Mousepad Hot Gift Game

The Doctor Valentino Rossi 46 Moto GP Logo Mouse Pad Mat Mousepad Hot Gift Game

Kingsley Machine Type -18pt. Park Avenue- hot foil stampiong Machine

Antique Original Kingsley Gold Stamp Machine With Many Accessories

NUMBERALL 40B STAMP MARKING PRESS PET SHOP/DOG TAG MACHINE

VTG ADDRESSOGRAPH MULTIGRAPH EXPOSURE FRAME 1470 Light Lamp Antique Industrial

Camera Lens Custom Name Tag Badge ID Pin Magnet for Photographers Photography

Caduceus Red Custom Name Tag Badge ID Pin Magnet for Nurse Doctor Medical Tech

Caduceus Gold White Custom Name Tag Badge ID Pin Magnet for Nurse Doctor Medical

Caduceus Gold Black Custom Name Tag Badge ID Pin Magnet for Nurse Doctor Medical

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies