US $1700

Directions

Similar products from Paints, Powders & Coatings

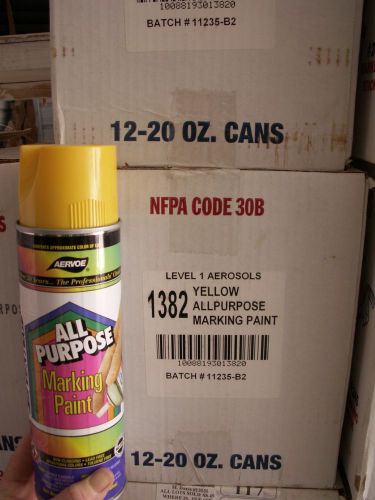

Aervoe 1382 Inverted Marking Paint Yellow Case of 12 cans Spray Paint

Plasti Dip Blaze Pink spray pack of (6) 11 oz cans

Plasti Dip Blaze Green spray pack of (6) 11 oz cans

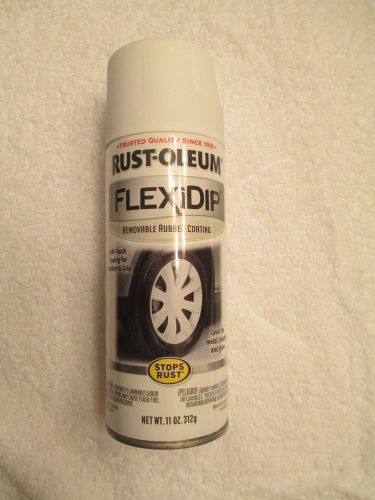

Rust-Oleum FlexiDip 11 oz. White Spray Paint 276290 - Matte White

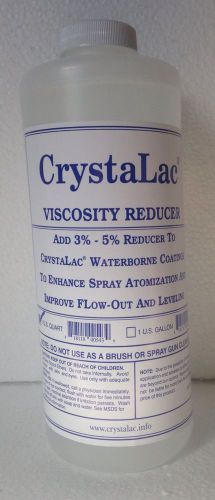

Crystalac Viscosity Reducer Quart

Powder Coating Coat Paint - Stainless Steel (Bonded) 1LB New Virgin Powder

Wooster Premiun Grade Wall&Trim 2 1/2 inch brush. Since 1851

Satin Black Powder Coat Powder Paint Low Gloss Black 1lb

GEMA 121517 PG-2A CABLE ASSEMBLY NEW UNUSED 11M POWDER PAINT

PARKER PARFLEX NYLON TUBING NB-4-062-0100 NEW IN PACKAGE 100 FT POWDER PAINT

60lb Interpon 600 Powder Coating JL335QF Silver Low Gloss Metallic Texture $425+

Dynaflux Spray Calv Metallic Zinc Coating

Surf Source Epoxy 1.5gal KIT/1gal res+2:32oz hrdnr

Gloss Transparent Candy GREY topcoat powder coating paint 3 oz, BUY 2 - GET 1 Lb

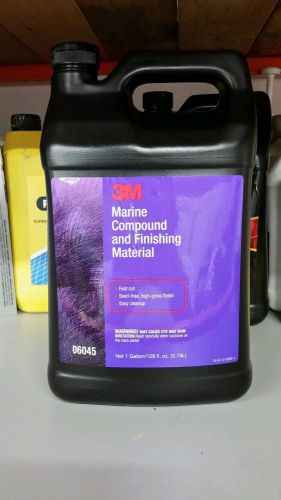

3M 06045 Imperial Compound Finishing Material 1 GAL Auto Body, Marine, Boat Comp

Racer Dip Liquid Rubber Car Paint Color Plastic Dip 1L ULTRA BLACK Flussigfolie

28 Oz Multi Purpose Spray 3 Pack Assorted Colors

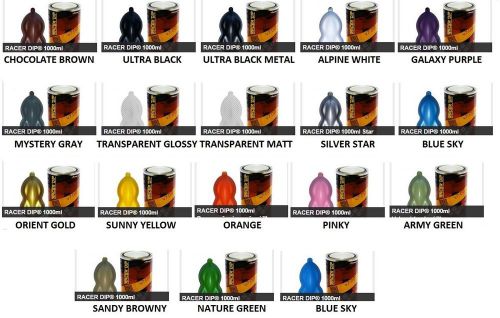

4 LITRES Racer Dip Flussigfolie Car latex Paint Plastic Dip ULTRA ALL COLORS

Racer Dip, Plastic Dip, Liquid Rubber, Flussigfolie, Car Paint 1L ALL COLLORS

Racer Dip, Plastic Dip, Liquid Rubber, Flussigfolie, Car Paint 1L SILVER CHROME

People who viewed this item also vieved

Nordic-Ware 46603 NordicWare Rectangular Cake Pan With Lid-9X13 CAKE PAN W/LID

Trudeau 0991638 Trudeau Utensil Pot Clip-12PC UTENSIL CLP DISPLAY

Main Street Style Wireless Speaker-INDR/OUTDR WIRELESS SPKR

Schumacher SpeedCharge Ship 'n Shore 12V Battery Charger-12V BATTERY STRT CHARGE

Gama Sonic GS-16LD Shed Solar Light-SHED SOLAR LIGHT

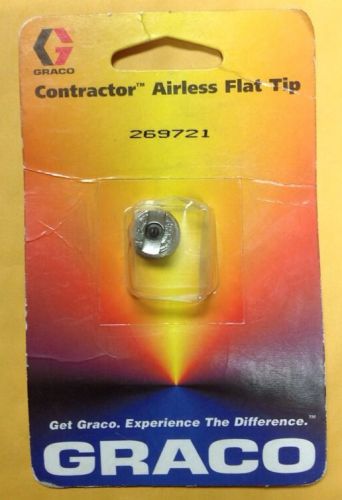

Graco 269721 Contractor Airless Flat Tip Size 721

Graco 24B790 Needle Kit 3/32 Carbide Ball

Level 360 Sanding Disc 150 Grit 5 Pack drywall paint finishing brush graco LOOK

DEVILBISS P-HC-4215 Connection for tubing withspring guard 1/4" 3/8" 240104

Graco Circuit Board 218405 218-405 for Ultra Airless Sprayer

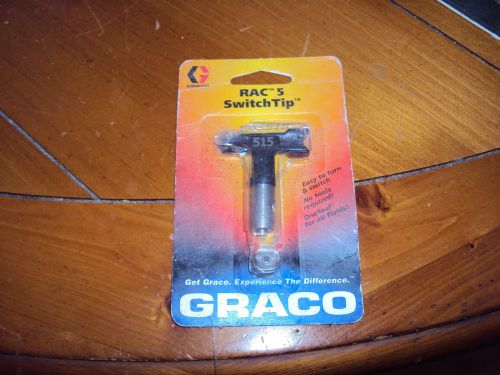

GRACO RAC 5 reversible spray tip 5 15

Milwaukee Wheel Assembly for a M4910-21 Paint Sprayer

Binks Paint Sprayer / Glue Gun Pot 2 Gallon Upholstery Supplies Used For Repair

SAMES 459351 320J50 DUAL SPRAYER GUN ADAPTER EFC 60 DEG RDC-089864 - FREE SHIP!!

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies