US $24,750.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Country/Region of Manufacture | United States |

Directions

Similar products from Cachets & Wafers

Applied Materials AMAT 0010-60017 Susceptor ENH Giant Gap 5" Ceramic Assy. NIT

NEW Applied Materials AMAT 0010-03175 Susceptor Assembly 200mm TEOS 8" Ceramic

Temescal 0916-8294-0 High Performance HP Emitter Assembly for Electron Beam

Tamarack Scientific 3 Axis Laser Ablation Positioning Stage $700

Brooks Automation Wafer Transfer Robot, Linear Track+Series 8 Controller+Aligner

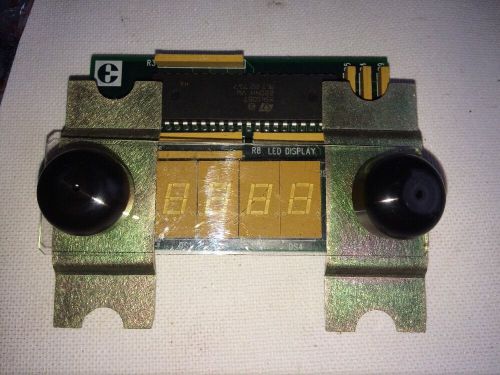

Electroglas LED Display Assembly 245439-001 Rev. E

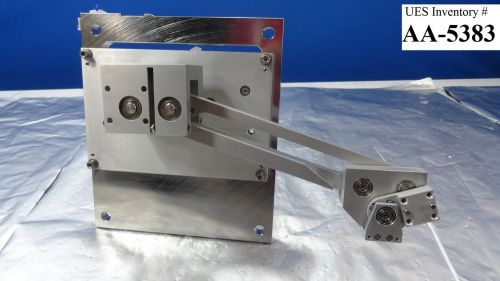

GaSonics A-2000LL Wafer Loader Transfer Arm missing end effector used works

Tunsgten (w) 1.750" dia x 0.210" thk .159.9 g

Mactronix STM-600 Wafer Handler Processor Slide Transfer Module Assembly

OTB SPIN JET SURFACE TREATMENT SYSTEM MACHINE

New Cerac High Purity Indium-Tin Oxide Sputtering Target Mounted Five Inch L281

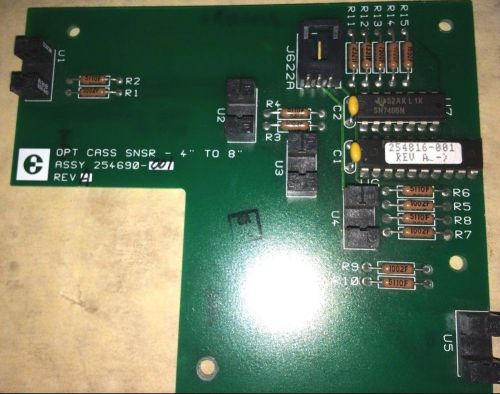

Electroglas 254690-001 OPT CASS SNSR Rev A

EQUIPE,PRI,BROOKS PRE-200 ALIGNER,REFURBISHED

AMAT AKT High Voltage HV-Supply Interface 0101-57025 Board Applied Materials

NEW AMAT AKT Column Control Board COL-C Applied Materials 0101-57012 / Warranty

NEW AMAT AKT Measurement Control Board 0101-57015 Applied Materials MEA-C 50-03

People who viewed this item also vieved

Zero-Max Servoclass, SC 040, Coupling ROHS, AMAT 0760-01032, 405960

Lot of 4 each / ENI DCG-100 DC / DCG2D-A031100021I - 500v & 800v models Wrnty

AMAT 0010-18158 GAS PALLET ASSY USG REG ULTIMA HDP-CVD Farmon ID 405903

MITUTOYO CMMC-35 Measuring Machine Control price

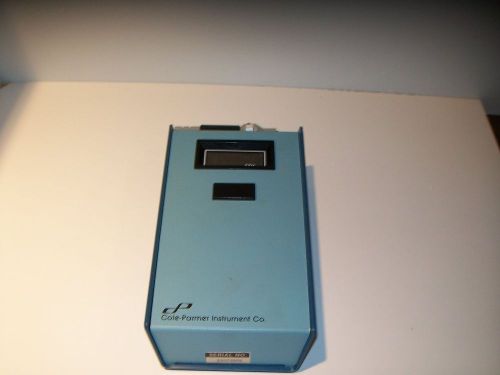

COLE PARMER INSTRUMENTS MODEL 8205 Digital Phototach

XB-200SRYZ, FAB XB-200SR-YP, Power Supply, PCB, 4060340

Gespac GESPIA-4, PCB, Board, 406089

WinSystems PCM-UI048A, FAB 400-0255-00B, 406088

AMAT 3300-03210 FTG, TBG, Flex 1/4 VCR-MF, 100PSI, .006"WL, 406148

Semiconductor Equipment Corp. Model 4800 SN 4800-1499 Vacuum Temp Controller

8902 SIMCO AEROSTAT XC IONIZING AIR BLOWER W/ HEAT PN: 4002612

SIGNATONE Wafer Probe Station-analytic Probing Microscope Station

STANFORD RESEARCH SRS RGA 100 GAS ANALYZER

EUBANKS MODEL #2600 WIRE STRIPPER (#1119)

Marpet Enterprises Mech-El 1204W Wedge Wire Bonder Gold Bonding

XYZ MICROMANIPULATOR PROBE Model 550

Terra Universal Dual Purge wih NitroWatch and Sensor

Thermonics T-2420BV Precision Temperature Forcing System

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies