C $7.99

Directions

Similar products from Solder

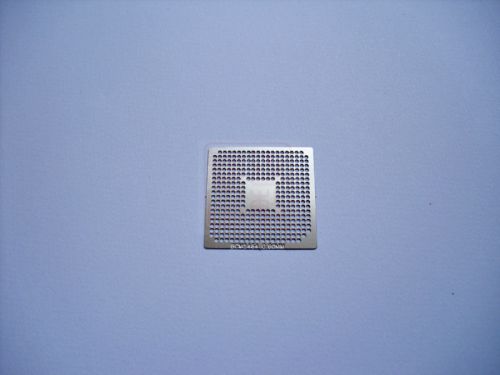

New For ETC BCM5464 BGA Reball Stencil template

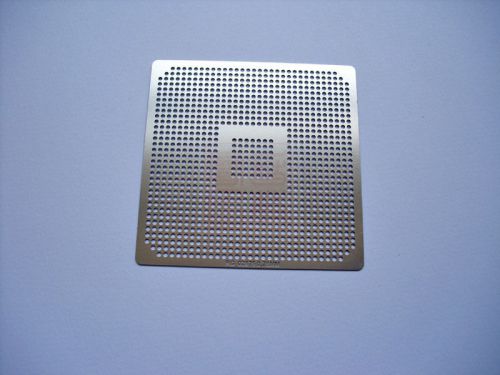

New For INTEL RG82875 RG 82875 BGA Stencil template

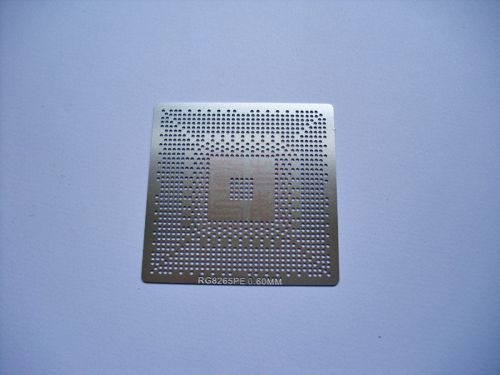

INTEL RG82865PE RG82865GV RG82865G RG82845G BGA Stencil

10mm X 100ft Kapton tape High Temperature Resistant

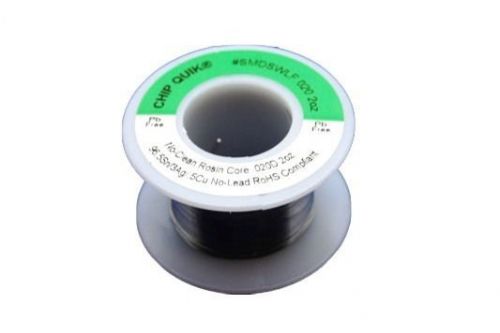

Wire SAC 305 No-Clean Core .020, 2 oz

Wire SAC 305 No-Clean Core .020, 4oz

BEST 0.4mm 10g New Lead Roll Core Soldering Solder Wire Tin Solder Welding Iron

CHIP QUIK Solder Paste in a Jar - 250 grams

Hot 9 in 1 220V 60W Electric Solder Tool Kit Set With Iron Stand Desolder Pump

3pcs/lot Advanced Repair Tool Solder Soldering Paste 10cc Flux Grease RMA-223 US

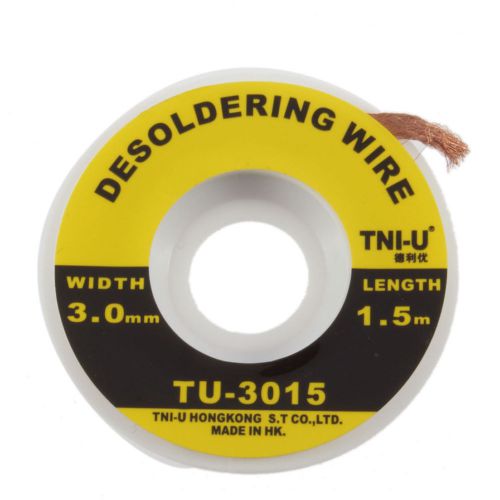

Security 5 ft. 3 mm Desoldering Braid Solder Remover Wick TNI-U TU - 3015new DG

LOT 2 x 20 LB SPOOL BOW ELECTRONICS 20/80 SOLDER WIRE stained glass

4 Pcs/Kit Mini Portable Silver White Different Shapes BGA Tweezers

NEW RoHS Solder Soldering Paste Repair Free Sn42 /Bi58 ZK158 High intensity

Security 5 ft. 3 mm Desoldering Braid Solder Remover Wick TNI-U TU - 3015new SU

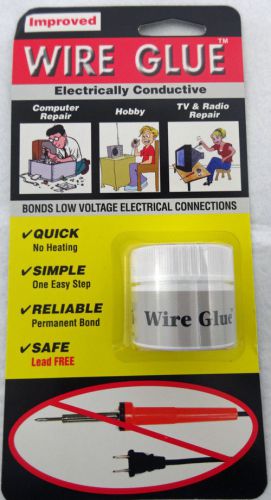

1 Wire glue Electrically conductive glue Bond low voltage electrical connections

0.8mm Leadfree Resin Flux Rosin Cor Welding Solder Soldering Wire Sn99Ag0.3Cu0.7

80g Rosin Soldering Paste Aid Auxiliary Solder Cables Soldering Iron new 8759

50g Rosin Soldering Paste Aid Auxiliary Solder Cables Soldering Iron

3 mm Desoldering Wire Braid Solder Remover Copper Wick 1.5m length

People who viewed this item also vieved

1x GOOT BS-10 Soldering Welding Aids Good Paste , Japan

BEST 600W 220V SELL 240mmx60mm Bottom Heat Plate Infrared Ceramic Heating Plate

220V Soldering Smoke Absorber Fume Extractor Sponge Air Filter Smoking Fan

100pcs M2*12 Bolt Screw Spike Screw ?2mm Length 12mm Round Head

WELLER SOLDERING IRON EC1201A 40 W

Metcal MX-500P-11 2-Port SMT Soldering / Rework Station + 2 wands

39-in-1 BGA Template Stencils for A5 HTC Mobile Phone Serials Reballing

Demo Weller EC1002-A Power Unit Without Pencil/Iron

3 New Hakko 900M-T-1.6D Soldering Tips One of the most popular Sizes Fits Many

3 New Hakko 900M Soldering Tips, T-1.2D,T-1.6D,& T-2.4D Popular Sizes Fits Many

~NEW~ OKI REPLACEABLE HEATER TIP PHT-650315

~NEW~ OKI REPLACEMENT HEATER TIP PHT-650335

WELLER TIPS AND TUBE FOR TC201 SOLDER IRON -- FPTI DITI TUBE

BRAND NEW HAKKO NO. B1550 TERMINAL FOR 902, 903, 648, 649 LOT OF 5

BRAND NEW HAKKO NO. B1810 HANDLE WITH COVER

HAKKO A1321 24V-50W HEATING ELEMENT FOR 900M*900L*907*908*913*914*951*952 IRONS

Weller WHA-2000 Hot Air De-Soldering Station (incomplete)

ESICO Model 12 Solder Pot 200 Watt 120 Volt New

FREE SHIPPING Power Probe PPSK Butane Soldering Kit ,NEW IN BOX

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies