US $625.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

product ID | 13482 |

Directions

Similar products from Other

AV1 Audio/Visual Light (RED COLOR) 120VAC 60Hz

Engine Cradle Stand Chevrolet Chevy Chrysler V8 1000lb with Dolly Wheels

Mitutoyo 543-693B LCD Digimatic Indicator 0.5"/0-12.7mm Range

CW-3000 Industrial Water Chiller, 0.8KW / 1.5KW Multi - heads Spindle Cooling

Rane AC22 Active Crossover with dj case

CW-5200BK Industrial Water Chiller AC 1P 220V, 60Hz

Consew Model 10 Gray Bag Sealant 110V

Box Fan Industrial - Belt Drive - 40" - 115V - 1/2 Hp - 1 Phase

CW-3000H Industrial Water Chiller for 0.8KW / 1.5KW Spindle Cooling, 1P

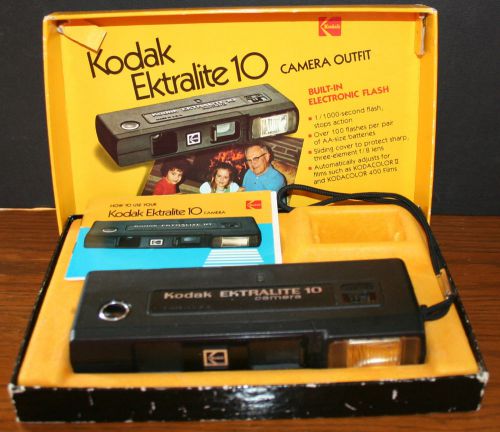

Kodak Echachrome 10 Camera with box and instructions, EXCELLENT!

Vacu-Lifter Suction Cup Panel lifter Alumnum 10"

Dynatron Bondo 354 Dynatron Yellow Spreaders

Dynatron Bondo 344 Dynatron Yellow Spreaders

Small Size Electric Cutting Machine

Reese Towpower 3 1/4 Inch Drop 2" Ball

100mm Diameter Tungsten Saw Blade, Cutting Blade, Cut SS, Aluminum, Acrylic PVC

(Forklift)BHS BTC-24MPP Battery Transfer Carriage with Push/Pull Loader

Dewalt Inspection Camera DCT410S1

MATCO DIAL INDICATOR SET with Pliers Part # DILP10A

People who viewed this item also vieved

2 Qual Craf Roofing Brackets #2505 6x90 fixed pitch

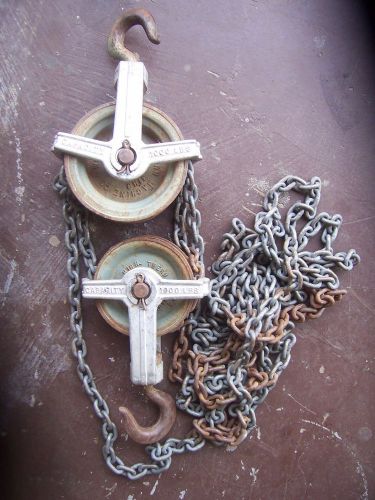

VINTAGE CRAFTSMAN MINN THERN MACHINE CO. 1/2 TON CHAIN HOIST 25 FT. CHAIN

Greenlee Paladin Tools PA70007 DataShark Network Tool Kit

GENUINE Makita Batterii BL1840 18V 4.0Ah Li-ion

7" Surface Prep Double Row Diamond Grinding Cup Wheel 7/8" Non- Threaded Arbor

Leister Hot-Air Blower Type Triac S CH-6060

IMPERIAL 600F WORM GEARED BENDER TUBE PIPE BENDER GREAT SHAPE

Kohler 20 KW Diesel trailer mounted

20 hp air compressor 230/460 volts

Hitachi 984-509 984509 Seal Lock Hex Socket Head Bolt M5x14 20 Types of Tools

Kushlan Cement Mixer LOCAL PICK UP ONLY OXFORD CT

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies