US $810

Directions

Similar products from Porcelain Dental Materials

NEW Ivoclar E-Max Press Ingots LT A1 Emax REF # 605274

NEW Ivoclar E-Max Press Ingots LT B1 Emax REF # 605277

NEW Ivoclar E-Max Press Ingots L HT A2 Emax REF # 626337

![Ivoclar Vivadent Emax LT Ingots [20]](/_content/items/images/15/4803015/001.jpg)

Ivoclar Vivadent Emax LT Ingots [20]

Ivoclar E-Max Press Ingots 1X HT C3, 2X LT A1, 2X LT B1, 2X LT D3

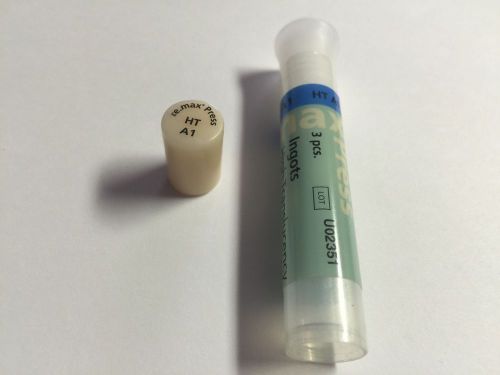

NEW Ivoclar E-Max Press 1 Ingots L HT A1 Emax

NEW Ivoclar E-Max Press 4 Ingots HT A2 Emax

NEW Ivoclar E-Max Press Ingots HT A1 Emax REF # 626320

Kuraray CLEARFIL REPAIR SE BOND Primer Bond w/ Porcelain Bond Activator Bottle

Porcelian Sampler Kit, #7010, by Smile Line. Original Kit $225.95

ZIRCONIA BLOCKS CAD/CAM 95x25m for ZIRKONZAHN Super Translucent US DENTAL DEPOT

ZIRCONIA BLOCKS CAD/CAM 95x22m for ZIRKONZAHN Super Translucent US DENTAL DEPOT

ZIRCONIA BLOCKS CAD/CAM 95x20m for ZIRKONZAHN Super Translucent US DENTAL DEPOT

ZIRCONIA BLOCK SUPER TRANSLUCENT for CEREC SYSTEM 20x19x15mm -10 Blocks- 112234

ZIRCONIA BLOCK SUPER TRANSLUCENT for CEREC SYSTEM 85x40x22mm -2 Blocks- 114350

ZIRCONIA BLOCK SUPER TRANSLUCENT for CEREC SYSTEM 65x25x22mm -4 Blocks- 112239

ZIRCONIA BLOCK SUPER TRANSLUCENT for CEREC SYSTEM 55x19x15mm 2 pins-5pk- 112238

ZIRCONIA BLOCK SUPER TRANSLUCENT for CEREC SYSTEM 55x19x15mm 1 pin -5pk- 112237

ZIRCONIA BLOCK SUPER TRANSLUCENT for CEREC SYSTEM 40x19x15mm -6 Blocks- 112236

ZIRCONIA BLOCK SUPER TRANSLUCENT for CEREC SYSTEM 40x15x15mm -8 Blocks- 112235

People who viewed this item also vieved

Denar Whip Mix Mark II Dental Lab Occlusion Articulator w/ Storage Case

Hanau Wide-Vue Dental Lab Occlusion Instrument Articulator w/ Storage Case

5X Dental Lab Adjustable Articulator Silver Alloy Occlusors Middle Size SALE

Sam 3 articulator complete incisal assembly

**********HANAU 96 H2 SEMI-ADJUSTABLE TEFLON COATED ARTICULATOR**********

ACRYLIC UPPER & LOWER COMPLETE SET DENTURE TEETH A1 7 SETS

Dental 20:1 Reduction Contra Angle Implant for E Latch Type Low speed handpiece

5PCS Dental High Speed Push Button Handpiece Large Torque with Quick Coupler 4H

BLUE Dental Surgical Binocular Loupes 3.5x 420mm Glasses + LED HeadLight Lamp

Dental Lab Equipment: Hanau Flask Compress

Dental Bulb Halogen Reflector Lamp Faro FDS DZE T4 GZ 9.5 24V 150W STAR5

Dental Bulb Halogen Reflector Lamp Pin Flat 14V 35W /1 pcs STAR5 Original

Dental Bulb Halogen Reflector Lamp Pin Round 14V 35W /1 pcs STAR5 Original

Honeycomb Tray with 20 Ceramic Pins

Single Large Porcelain Mixing Tray

10pcs/5sets Dental Disposable Impression Trays Autoclavable Anterior Upper/Lower

New 10 Pcs 5 Pairs Dental Disposable impression trays II Reusable Colored 1 Set

Lot of 153 Kerr Dental Files/Reamers

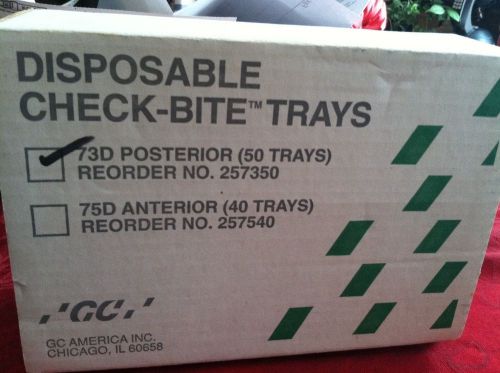

42 Disposable Check-bite trays GC America

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies