US $11.58

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Unbranded/Generic |

| Country/Region of Manufacture | China | ||

| MPN | Does Not Apply | ||

| UPC | Does not apply |

Directions

Similar products from Multimeters & Insulation Testers

ALL-SPEC AMMETER JB8018 METER GAUGE DIAL INDICATOR HS-1 GAGE 0-100UADC NEW

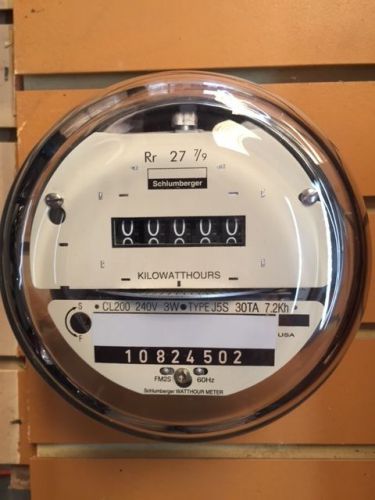

New In Box Schlumberger Watthour Meter TYPE J5S30TA 7.2 KH CL200 240V 3W

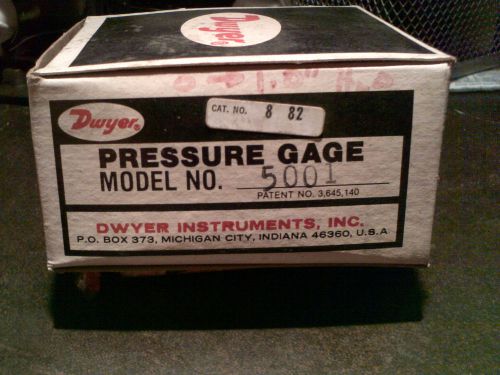

Dwyer Pressure Gauge, Model 5001, NEW in box

OSAKI 240V single phase watthour MINI meter OB9WHT 10A Current transformer LISTA

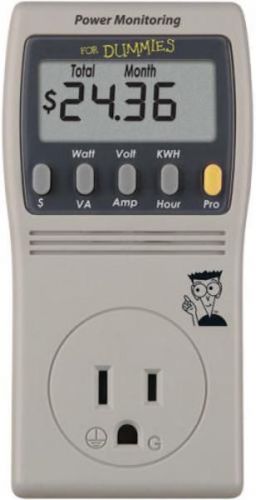

WMU P3 - Power Monitoring for Dummies SAVE MONEY ELECTRIC BILL EASY HOME OFFICE

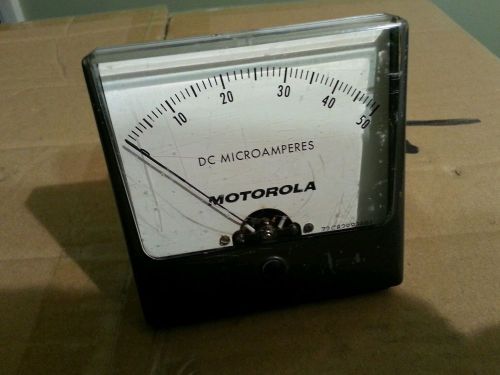

SIMPSON 0-50 DC MICROAMPERES MOTOROLA 3-1/2 INCH Steel PANEL METER 72C82993B01

Vintage Simpson Model 150 Amp Clamp In Box With Paperwork

Kane May SGA91A CO Carbon Monoxide Analyser

NEW Fluke 80B K-Type Thermocouple Fluke

Kill A Watt EZ electricity usage monitor model P4460.01 **EXCELLENT CONDITION**

SWITCH, KEY, KEYLOCK,LOT OF 2 YM061U2C2WCNQ

Salisbury 4356 Kit with 4244 Voltage Detector 240V - 230 kV New

Megger MIT410 Insulation and Continuity Tester New in Box MFR Warranty + Cal

Klein-Tools CL100 Clamp Meter with Leads and pouch Electrician test kit

HIPOTRONICS PORTABLE DIELECTRIC OIL TESTER OC60D

Vintage Cast Iron Metal 4 Dial Electric Kilowatt Hours Service Meter

Array 3721A Programmable DC Electronic Load 40A 80V 400W

RadioShack 42 Range DigitaL Multimeter 2200811

ENIDINE CONVOLUTED AIR SPRING YI-2B14-352

People who viewed this item also vieved

General Electric GL 7580 Duplex Locking Receptacle

Advanced Micro Controls Inc. iPCE User Manual

ALLEN BRADLEY ControlLogix Analog I/O Modules User Guide, NEW

HUBBELL WIRING DEVICE-KELLEMS HBLPOB1D Portable Outlet Box,Yellow,Duplex

ABS Plastic Project Enclosure Box Radio Shack 270-1803 5x2.5x2" 127x63.5x50.8 mm

DIY metal project box 4" x 8" x 2" ITT POMONA Electronics E11182

NEW!!!!!!! SQ. D PART# QO142L225GRB

WESTINGHOUSE NBA 100A AMP 120/240V-AC DISTRIBUTION PANEL BOARD B437254

Schneider/Square D J250R Circuit Breaker Enclosure Series A01 15-250 Amp NEMA 3R

CYBERDATA CD-011049 SIP CALL BUTTON

ICC IC1078F6YL MODULE, CAT 6, HD, YELLOW

New 1xMC68060RC50 MOTOROLA 90 days warranty

Fanuc A20B-8002-0631 90 days warranty

NEW 2711-T10C16L1 Touch screen glass

TRACO POWER ART.NR.4020004 POWER SUPPLY

AC Adapter 24V AC 600mA (0.6A) 120V input 18 pcs power

NIB TRACO MODEL ESP36-153D 36W POWER SUPPLY

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies