US $53

Directions

Similar products from Jobber Drills

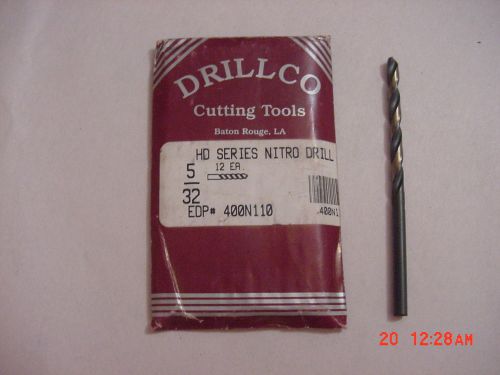

>New< Drillco Drill Bits 5/32 HD Series Nitro Drill EDP# 400N110 USA

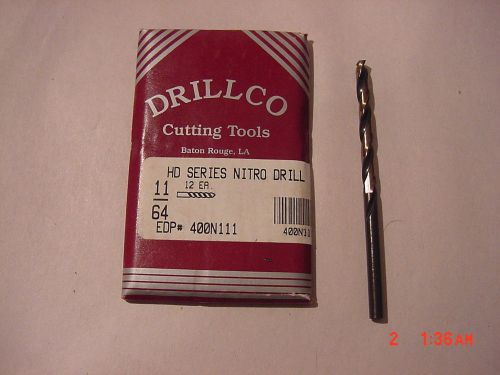

>New< Drillco Drill Bits 11/64 HD Series Nitro Drill EDP# 400N111 USA

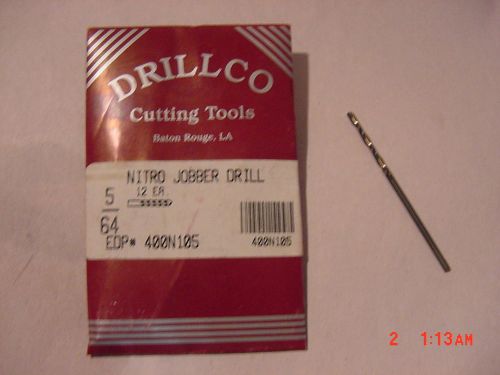

>New< Drillco Drill Bits 5/64 HD Series Nitro Jobber Drill EDP# 400N105 USA

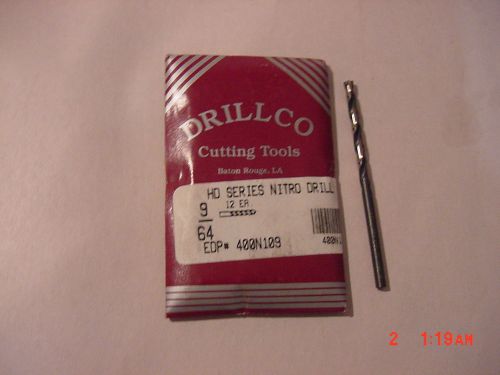

>New< Drillco Drill Bits 9/64 HD Series Nitro Drill EDP# 400N109 USA

Lot Of 8 17/64 CL 2656 Chicago Latrobe Drill Bits C-L

Guehring 00605-14,500 Type Ti Jobber Drill Spiral

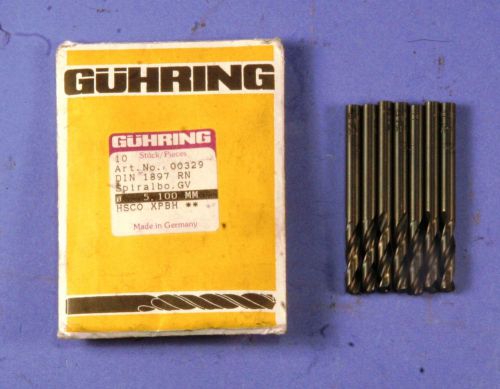

7 Guhring 00329 Spiral 5,100 mm HSCO XPBH

MICHIGAN DRILL Michigan Drill 208A Series High-Speed Steel Extra Long Drill Bit,

Guehring 00605-11,110 Type Ti Jobber Drill Spiral

Drill Index HUOT * Letter * Number * Fractional * All Metal Design

19/32" x 6" EIP HS USA precision

Precision Twist Drill - 1 to 13 mm, 118 Degree Point Degree Oxide Finish High Sp

ASIMETO 500-82-3 2MM RUBY POINT FOR.060"TEST INDICATORS

Letter C Jobber Drill, Chicago Latrobe

Letter P Jobber Drill, Chicago Latrobe

Letter B Jobber Drill, Chicago Latrobe

Letter I Jobber Drill, Chicago Latrobe

Letter J Jobber Drill, Chicago Latrobe

Letter N Jobber Drill, Chicago Latrobe

People who viewed this item also vieved

MITSUBISHI MZS05312MB VP15TF (FREE SHIPPING)

SECO Perfomax 1.25" 3XD Drill w/ 20 new inserts! SD503-1250-375-1500R7 *NEW*

MITSUBISHI MZS04219LB VP15TF (FREE SHIPPING)

PTD Precision Twist 3/4" X 10" Length Drill Bit HS Black Oxide

PTD Precision Twist 3/4" x 9/16" X 10" Length Drill Bit HS Black Oxide

PTD Precision Twist 3/4" x 5/8" X 10" Length Drill Bit HS Black Oxide

NEW SANDVIK INDEXABLE DRILL WITH INSERTS R416.2-1000 P31-41 STK 1121

Kennametal 21mm, .8268" flat bottom, solid carbide, thru-coolant drill

1/2" 82 DEGREE HSS SINGLE FLUTE COUNTERSINK

WALTER TITEX A6589DPP-8.5 Coolant Fed Drill,K30F,Solid Carbide G7894302

WALTER TITEX A1166-14.9 Jobber Drill,Solid Carbide,4 in. L G8098736

OSG TAP & DIE SOLID CARBIDE ENDMILL 7/16 DIA 4 FLUTE P/N 464-4375

2" HSS MORSE TAPER DRILL BIT 17" OAL

American Vermont 7/16" High Speed Steel 1/4" Shank Drill NEW USA -LOT OF 2-

Precision Twist High Speed Steel 7/16" Drill 118 Degree 4 1/16" Flute 5 1/2"

SCREW MACHINE DRILL 3/8" COBALT TIN PARABOLIC 130 SPLIT POINT TITEX NEW $7.45

SCREW MACHINE DRILL 15/64" HIGH SPEED 118 POINT BLACK OX TITEX NEW 10 PCS $12.80

SCREW MACHINE DRILL 15/32" COBALT TIN PARABOLIC 130 SPLIT POINT TITEX NEW $11.65

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies