US $920

Directions

Similar products from Temperature Controlling Devices

ATHENA MODEL 5000-S-E 0-1000F TEMPERATURE CONTROLLER (A)

Inside Out Networks Watchport/H Humid/Temp Sensor

Glas-Col 100AO621 Heating Mantle

0-100C (Laboratory Glass) Brand New Liquid Indicator Thermometer Glass Red D

Cole-Parmer Instruments Model 2157 Dyna-Sense Electronic Temperature Controller

Marlow Temperature Controller SE1012 *FOR PARTS*

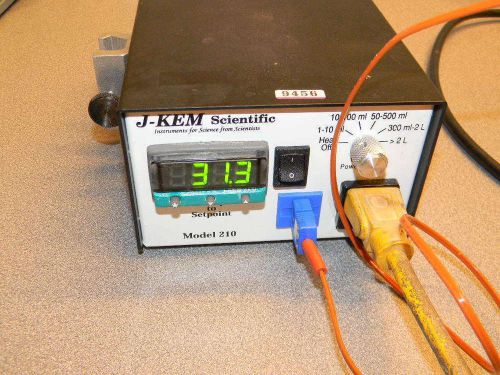

J-KEM Model 210 (for a Type T Thermocouple), W USB Interface

J-KEM 260/Timer (for a Type T Thermocouple), W USB Port and Type T Thermocouple

QNW Quantum Northwest TC125 Temperature Control Controller CD250

(3) Yellow Springs Instruments (YSI) Thermistemp Temperature Controller 71A

@@ YAMATAKE AZBIL DMC50 MULTI-LOOP CONTROLLER

J Kem Temperature Controller Model 270

Milwaukee DL125 pH / ORP Temperature Controller with WiFi and Dual Data Logging

@@ YAMATAKE AZBIL DMC50 MULTI-LOOP CONTROLLER - INCLUDES 2

Fisher Paykel 900MR869 Temperature Probe For Heater NEW 3871

Vintage Taylor Instrument Co Termperature Recorder Printer Lucite Box

People who viewed this item also vieved

Opti-Chem CG-3498 Temperature Controller

Chromalox ROPH-121 HOTPLATE Lab Warmer 120V 1200W PN 196 032951 003

Cryogenic Cryo Storage Rack Stainless Steel Freezer Rack 4 Shelves/25 Vial Box

VACUUM FLASK - GLASS DEWAR - 14" tall 2 1/2" diameter -a

TENNEY T30RC ENVIRONMENTAL CHAMBER

TABAI ESPEC CORP. PR-2GM PLATINOUS RAINBOW TEMPERATURE AND HUMIDITY CHAMBER

Revco 5 Compartment Freezer Model ULT2186-7-AUA

Zbag Big Size Thermo Insulated Bag Soft Cooler

GLAS-COL ZIPVAP ZIP-VAP 96 PIN WELL EVAPORATOR CONCENTRATOR 9600E MICROPLATE

Fume Hood, Fisher Hamilton Bench Included, Cleaned, 8 Feet

ESCO Hood CLASS II TYPE A2 Model#LA2-4A2

1200W Ultrasonic Processor for Dispersing, Homogenizing and Mixing Liquid Chemic

HEADBAND Excellent Quality FREE SHIPPING

Yamato Gravity Convection Ovens, DX Series, Yamato DX 300

Waring Two-Speed Laboratory Blenders, 1L, Waring 7010G Blenders With Timer

Waring Single-Speed Blenders, 1L, Waring 700S Constant Temperature Unit

Neslab Endocal RTE-110 Heating/Circulating Water Bath Refrigerated Recirculator

SHELDON SHEL-LAB UNIVAR VWR SCIENTIFIC 1260 HEATED WATER BATH WATERBATH 600W

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies