US $379.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Forney |

| Power Source | 110/120V Electric | ||

| Model | 00306 306 | ||

| Current | 1 Phase | ||

| MPN | 00306 130FI | ||

| Country/Region of Manufacture | Italy | ||

| Processes | MIG |

Directions

Similar products from Electric Welder Machines

Miyachi-Unitek CY-160A Welder Control 160

Unitek Phasemaster PM V PMV 1-234-2 Welding Control PM5

Miller CST 280 Welding Machine

hobart wire welder 125ez inv# 2644

LINCOLN PYTHON PLUS PUSH PULL GUN 15' P/N K3038-1

X1 Unitek Welder Model 60 Watt SecondS

Miller CST 280 Stick/TIG Welder - 907244011

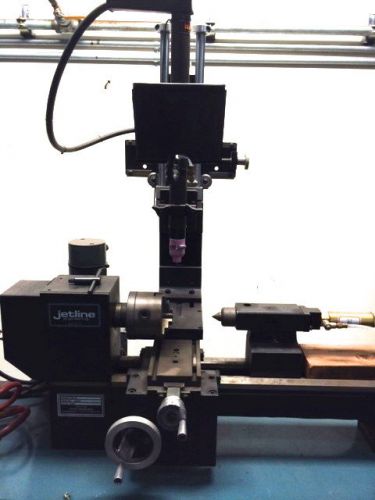

JETLINE AUTOMATED WELDING SYSTEM CWP-20Z SLIGHTLY USED

Miller Maxstar 150 STL Welding Machine.

Nelson Stud Welding Series 5000 Stud Welder

Lincoln Pro/cut 60 Amp 3 Phase Plasma Torch

Lincoln SA-200 Matte Black Iron Cross Knobs New Style BW833-BLK

Dimetrics Talley Centaur 150 PTW-1 orbital tubing welder, 110/120v electric TIG

SPEEDWAY SERIES ARC WELDER 100AMP 220V WELDING TOOL CONSTRUCTION

Matco Tools Mig Welder, Model WFW140, 110/120V Electric

People who viewed this item also vieved

MASTER QUALITY POWER MW71301 Welding & Cutting Kit

Nitrogen Regulator400 Psi Gauges

Oxygen and acetylene flash arrestors & check valves 88-sfbrr & 88-sfbrl

Mapp Cutting Torch Tip 2V FS-2385 No. 49 Welding

PLASMA CUTTING TIPS WELDING SUPPLIES CHICAGO ELECTRIC ITEM # 62771 FREE SHIPPING

CT-312 TIG120+MMA120+CUT30 TIG/MMA/Plasma cutter 3 In 1 Cutter Welding Machine

212730 Miller Genuine parts Drag Shield

212734 Miller genuine parts swirl ring

Harbor freight Chicago electric spot welder parts model 45689 parts only

Pair of used spot welder tongs 8.5"

Marquette 40 Amp Rocker Switch Assembly New 43600028

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies