US $319.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Armorcoat Epoxy |

| Model | Epoxy,Paint Flakes |

Directions

Similar products from Paints, Powders & Coatings

Lot of 3 AERVOE Black Upside Down Striping Paint 18 oz Cans

Lot of 3 New Paint Trim 4" Inch Roller Frames with Threaded Handles

Deft Polyurethane Topcoat Paint Kit 03-GY-287 (Gray 36320) 1 Gal

Deft Polyurethane Topcoat Paint Kit 03-GY-323 (Gray 36270) 1 Gal

Deft Polyurethane Topcoat Paint Kit 03-GY-330 (Gray 36118) 1 Gal

Deft Primer Coating Kit (09-Y-002) 1 Gal

Deft Primer Coating Kit (09-Y-002) 1 Pint

Deft Polyurethane Topcoat Paint Kit 03-W-127BF (White 17925) 1 Qt

Deft Polyurethane Topcoat Paint Kit 03-W-127BF (White 17925) 2 Gal

Deft Polyurethane Topcoat Paint Kit 03-BK-074 (Gunship Black 37038) 1 Qt

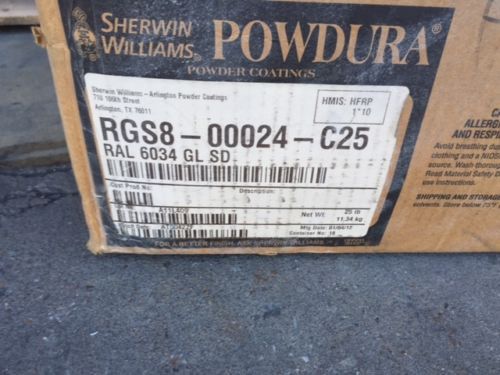

18 lbs Aqua RAL 6034 Powdercoat Paint

59 lbs Tuscan Red Powdercoat Paint

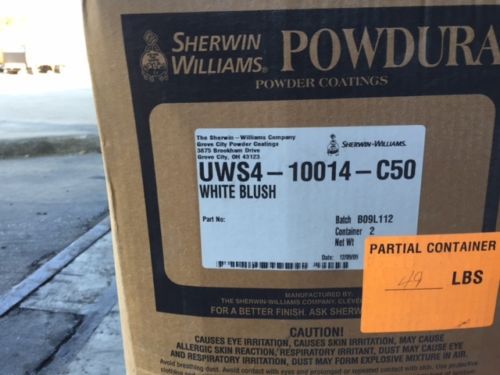

49 lbs White Blush Powdercoat Paint

23 lbs Blue 5013 Powdercoat Paint

13 lbs Blue 5005 Powdercoat Paint

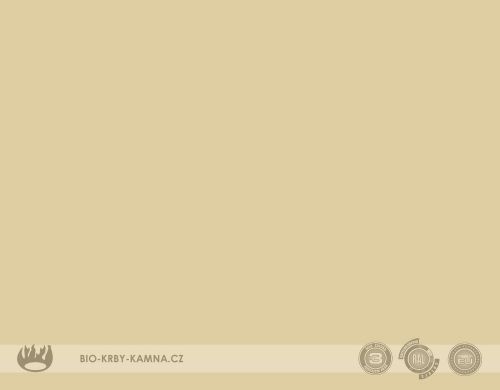

55 lbs Vanilla 1014 Powdercoat Paint

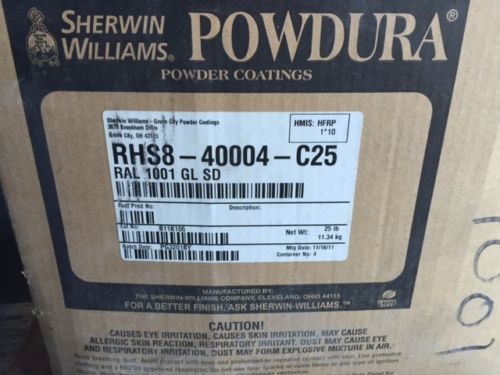

30 lbs RAL1001 Powdercoat Paint

Performix WHITE Plasti Dip 11207 11oz Can (6 PACK)

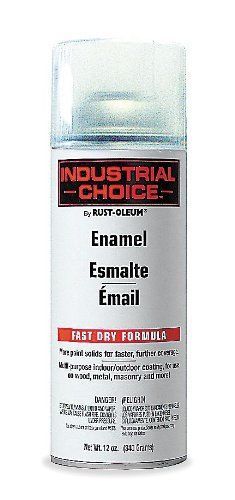

NEW Spray Paint Crystal Clear 12 oz.

People who viewed this item also vieved

NEW lamb skin paint roller MADE IN USA

Shur Line 3955108 Shur Line Deck Pad Painter-9" DECK PAD

LOT OF 9 PROVAL BRUSHES NEW THIS BRAND IS SELLING AT SHERWIN WILLIAMS STORE

Sherwin Williams Texture Paint Roller Cover 9", faux painting.

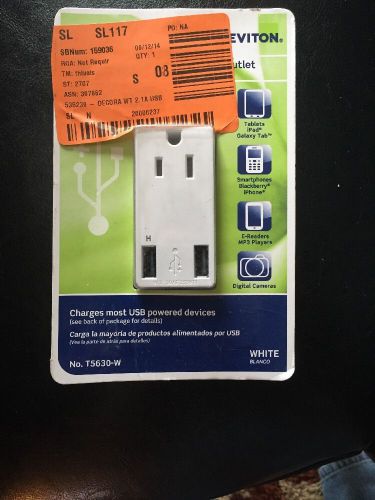

Leviton R02-T5630-00W Leviton USB Charging Outlet-2.1A WHT 2 USB/OUTLET

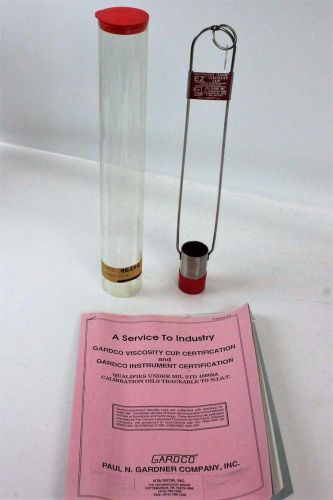

Gardco Dip Viscosity Cup VI-EZ4~N.O.S~in Tube package w/ Instructions More Avail

Henry Gardner Lab Viscosity Cup Ser No. 167~NEW OLD STOCK WITH ORIGINAL BOX

Heat reflective glass window for DIY Powder Coating Oven System 21 x 13 " (wb20)

3M (36853) Dirt Trap Protection Material, 36853, 56 in x 300 ft

3M (36851) Dirt Trap Protection Material, 36851, 14 in x 300 ft

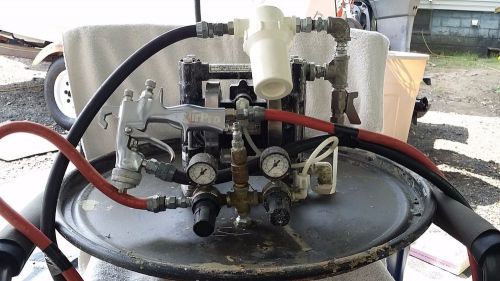

GRACO HUSKY 307 DRUM ADHESIVE SYSTEM W/ GRACO AIR PRO GUN

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies