US $210

Directions

Similar products from Linear Actuators & Bracket Stroke

IAI ROBO CYLINDER RCP2-RA4C-I-42P-5-250 Slider Type Steel Base Electric ACTUATOR

Thomson M75 TF07K729-A00S156P1 Rapidtrak Guided LinearRODLESS LINEAR ACTUATOR

Lot of 28 Thomson 60 Case Quick Shaft QS 1/4" Diameter - 6" Long

SBR12-1400mm LINEAR SLIDE GUIDE SHAFT 2 RAIL+4 SBR12LUU BEARING BLOCK CNC set

Actuator 120v 60Hz Barber Coleman MP 485- 0-2-2

Sargon Industries Precision Linear Glass Scale MG330-12

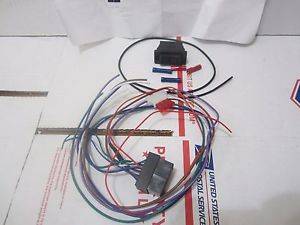

MPC 0462 Linear Actuators for Wiring, Switch and Relay Kit

Ball Screw Actuator, DUFF-NORTON, M9802-9G, 2 Ton,9 In TVL w/ free shipping

NEW PACIFIC 3/4" ID CLOSED SIMPLICITY PRECISION FLANGED PILLOW BLOCK SFP12

Konmison 300mm Travel Length Linear Stage Actuator DIY CNC Router Parts X Y Z...

Anycubic MR12 MGN12 Miniature Linear Guide Rail Way Slide and MGN12H Block fo...

IAI ROBO CYLINDER RCS-C-SSI-60-2 ACTUATOR TYPE ,200V SR:SSI50681 (61AT)

SWAGELOK ACTUATOR 133 BR ,90 DEG SPRING RETURN 7000005NC / CFM 7400-01(122AT)

Blodgett 50617 24-volt DC Two Stroke Actuator

Tsukasa TG-47C-VG-500-C249 geared 12v dc Motor cf67

20 Inch 20" Stroke Linear Actuator 12 Volt 12V 225 Pounds lbs Maximum Lift

WINDYNATION 6 Inch 6" Stroke Linear Actuator 12 Volt 12V 225 Pounds lbs Maxim...

Linear Actuator Mounting Brackets

People who viewed this item also vieved

SMC CDQ2A50-75D-A93L *NEW NO BOX*

SMC, MGGLB25-75-XC18 PNEUMATIC GUIDE CYLINDER...FREE SHIPPING !

LOT OF 8 INDRAMAT INPUT MODULE RM I-01 & RECO-G.06/01 EXPANSION

(L27-1) 1 NEW CHENTA GEAR 3122398 E-222265 INDUCTION MOTOR SZ18 1:20

KOLLMORGEN SERVO DISK DC MOTOR Mod. 00-00917-021 Type. U9M4HA/U6 -NEW-

LOT OF 8 INDRAMAT OUTPUT MODULE RM O-02 & RECO-E.00/01 EXPANSION

BAYSIDE SERVO GEAR REDUCER # PS142-020-010SH -NEW-

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies