US $9,750.00

| “This wrapper shows signs of use but is fully operational. It has been professionally restored to working order by a manufacturer-approved vendor. This means the product has been inspected, cleaned, and repaired to meet manufacturer specifications and is in working condition. This item may or may not be in the original packaging.” |

| Brand | Orion |

| MPN | HPA |

| Model | HPA |

| Country/Region of Manufacture | United States |

Directions

Similar products from Wrapping Materials & Tape

New Shurtape SD-999, No. 901000, for up to 1" Width Filament Tape Dispenser

Lot of 8 New Uline H-596 Tape Dispenser for 3" Wide Tape

EB100 Edge Banding System from Freud Used, As is, with free shipping!

REYNOLDS Food Service Film / Model: 914M Metro / Size: 18 Inches x 2000 Feet

Kamoikakoshi MTEX1P77 / MT EX Ticket 30mm Width x 10m Winding / Film Packaging

(2) PACK of 3M Scotch Transparent Tape 600-2P34-72, 3/4 in x 2592

Contrax® HD 719 Clear 2X1610 polypropylene strapping LOT OF 72 ROLLS

Brother TZ-2322 P Touch 3 pack (2) 12mm 1/2" (1) 9mm 3/8" white laminated tape

Heavy Duty Modular Furniture Roll Bar for Packaging / Shipping Tables D-9030

14 rolls Shurtape- Brand New FREE SHIPPING Warehouse Retail Packaging Tape Bulk

Brother Pentax Letter Size Paper, 100 sheets (PTX 201960), LB3635 Thermal Paper

scotch tape shipping packaging 43 yds each, 6 rolls total

KRAFT POSTAL/WRAPPING/SHIPPING/CRAFTING PAPER 48" X 200' NATURAL BROWN COLOR

New Uline H-356 Vertical Paper Cutter for 40-48" High Kraft Paper Rolls

NELSON WRAP DISPENSER COMANY NWD-1, WRAP DISPENSER, LIGHT WEIGHT, ALUMINUM

Dispenser + Fragile Handle With Care Preprinted Tape 36 Rolls 2" x 110 yds 2 mil

Used Packing Brown Paper Approximately 20' long 29.5" in width

Scotch Magic Tape, 3/4 x 1000 Inches, Boxed, 5 x12 = 60 Rolls (810K12) Free Ship

Scotch Cloth Duct Tape Roll 1.8" inch x 15 yards FREE SHIPPING !!!!!

Clear Sealing Tape Counter Top Display 64 Pieces

People who viewed this item also vieved

Shanklin T-7XL Heat Tunnel, Shrink Wrap Tunnel 14939

LIPSTICK MELTING MACHINE TECNICOIL MODEL F8-7.50C3R

SIGNODE CY-30 Cutter Steal Strapping

SIGNODE TH 34-114 Steel Strapping Tensioner

91211 New-No Box, Multivac 31007 Sensor, Longitudinal Stroke

91210 New-No Box, Multivac 10770155 Toothed Wheel, 14mm ID

91202 New-No Box, Multivac 80260478026 Gasket Rebuild Kit

91184 New-No Box, Multivac 19717206400 Washer 46mm OD, 7mm ID, 2mm Width

91181 New-No Box, Multivac 19717206300 Washer, 1/4" ID, 30mm OD, 3mm Width

1,000pcs 5/8" Metal Open Seals For Poly Strapping

Gerrard 1916 Strapping Tool and 1953 Crimper

ORGAPACK OR-T 200 Strapping Tool Battery Operated 12V Fromm Signode

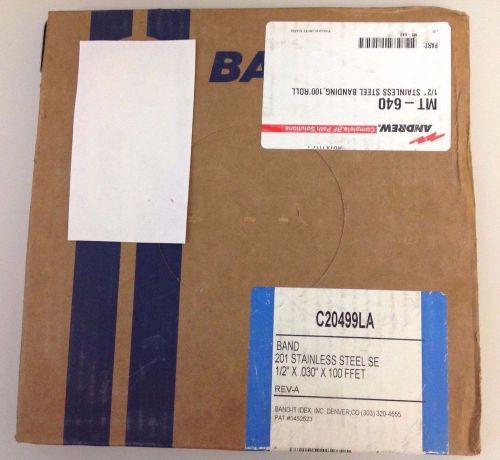

BAND-IT 201 Stainless 1/2" .030" 100’ Banding Strapping C204 C-204 MT-640 NEW

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies