US $11000

Directions

Similar products from Other Woodworking Equipment & Machines

DELTA 20-622 4" Quick Release Drill Press Vise

Shop Cart Panel Handler, used for Sheet Good Transport, Feeding and Storage

Grizzly 20 Inch Planer 3 Hp 240 Volt Single Phase

KREG POCKET HOLE JIG + SELF TAPPING POCKET SCREW KIT, SK03

Gannomat Model 260 Case Clamp 220V 3PH

Rockwell Craftsman 43-110 Wood Shaper 220 Volt Motor Included w/ Stand

Woodworking Vacuum Table Veneer Press Vacuum Forming

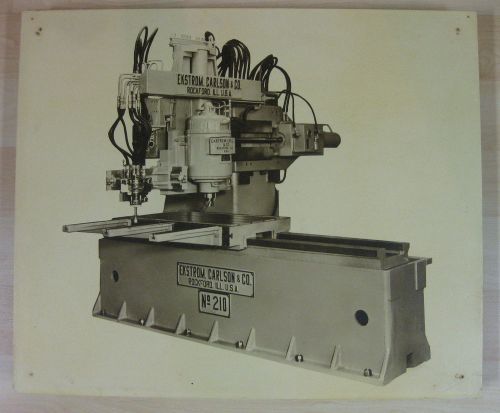

(9) RARE Vintage ROCKFORD ILLINOIS Ekstrom Carlson ROUTER LATHE 24 x 20 POSTERS

WOOD WORKING TABLE LAYOUT LAY OUT BENCH Adjustable Legs 44 & 1/4"x 74" & 1/2"

Adapa Panel Handler 4' Capacity Model HF-500 Hydraulic foot operated

Homag KL 73 A3 Edgebander with Ligmatech ZHR 01 Automatic Return Conveyor

Homag VFL-75 Postformer Post Former

DEWALT COMPACT STAPLER DWHTTR130LH **NEW OTHER**

MGM Transformer 30KVA w/Disconnect (Woodworking Machinery)

2006 Fuji Ring Vacuum/Blower w/Control Valves (Woodworking Machinery)

MGM 3-Phase 480V 75KVA Transformer (Woodworking Machinery)

2006 Eaton Cutler-Hammer 75KVA Transformer (Woodworking Machinery)

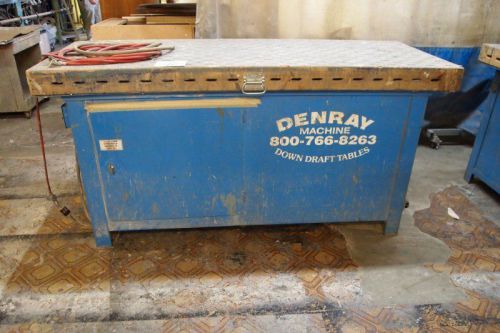

Denray DownDraft Table - Model 3660 (Woodworking Machinery)

People who viewed this item also vieved

Delta Unisaw 10" Tilting Arbor Saw (#12)

Oliver Model 4680 Horizontal Band Resaw

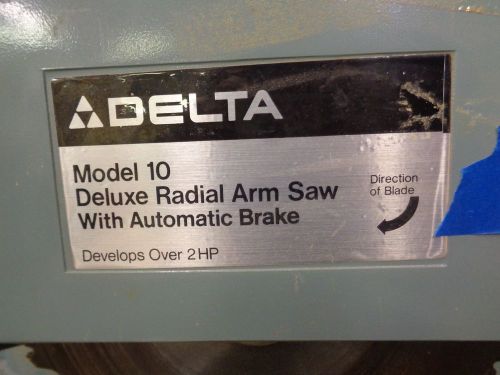

Delta Deluxe Radial Arm Saw with Automatic Brake, Model 10 (#1)

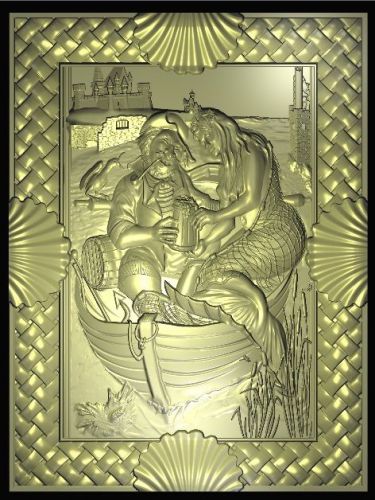

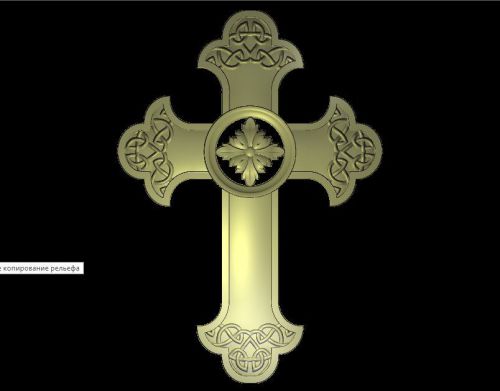

artcam 3d STL Model for CNC Router Machine Aspire Cross Relief Artcam 134

artcam 3d STL Model for CNC Router Machine Aspire Cross Relief Artcam 49

CNC ROUTER ENGRAVER ENGRAVING MACHINE 3020 DESKTOP DRILLING/MILLING a5

Ritter R700 2HP 4"x 60" Double Edge Sanding Belt Sander Edger Machine Door Tilt

Porter Cable 362V 4" x 24" Variable Speed Belt Sander

Skil Model 325 JY 525 Belt Sander 2.25" Sander Belts 6 7802 2 1/2 Grit NOS

Powermatic Drill Press Return Spring 18209 MPN 6813026 FITS 1150 &1200

Chicago Bench Drill Press, 5/8" Chuck, Model: DP-558-2 on Metal Stand

Craftsman 15" Drill Press, NO RESERVE, Meridian Airport Authority

Craftsman Wood Lathe 9x36 w/ STAND & MOTOR • • • NICE VINTAGE PROFESSIONAL TOOL

33 1/2" Wood Lathe Drill Bit with 2 Mt Taper

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies