US $9700

Directions

Similar products from Other Manufacturing Equipment & Tools

NOS BALL BEARING DELCO 1#773L13 AS IS BIN#ZP-7

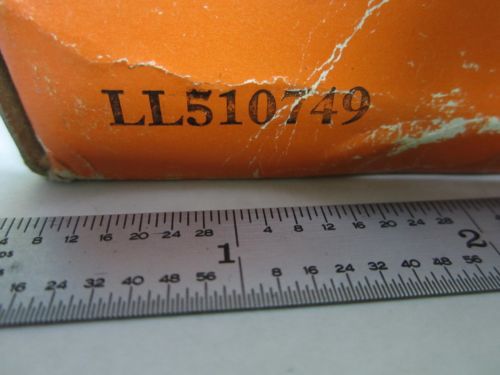

NOS BALL BEARING TIMKEN LL510749 AS IS BIN#ZP-7

New Holland 12" x 12" Spin Dryer Heated Spinner Great Condition DRY PARTS FAST!

99.9% CHARMILLES PURE TUNGSTEN POWER FEED CONTACT

Atlas Craftsman 10Lathe 8 inchDiameter Face Plate 1-1/2" 8 TPI with dog

Proto Dial Torque Wrench 0-175 FT LBs / 250 N-M 1/2" drive J6121NMF

Demagnetizer - 4.5XX6 - R.B. Annis Co. - 4.5" diameter hole and 6" Depth

G Dufour Universal Milling Machine, 43" x 10" Table.

Marking Methods 300 Etching Machine

300 pcs Hollow Brass Rivet,3mm*8.5mm(0.12inch*0.33inch)

50 foot roll leather belting, 1" x 1/8" chestnut color, craft, machine, art

Hood Latch Set of 2 Gloss Black good quality latches only strong spring

50 foot roll leather belting, 1" x 3/16" chestnut color, craft, machine, art

Burn-out Oven for Investment Casting,21 x20 Lane Refurbished ,w/o controls

10x 30 Degree 0.1mm Carbide Engraving Bits CNC Router Tool For PCB Board Pack

(6) Hertel Precision K Drill bits 0.2810" 6-1/4" OAL 135 deg .2810 HSS

NEW SUNNEN REPLACEMENT BELT MBB-810-A

Stewart Wattley / Yale 20 Ton Overhead Bridge Crane Hoist, 55' Span

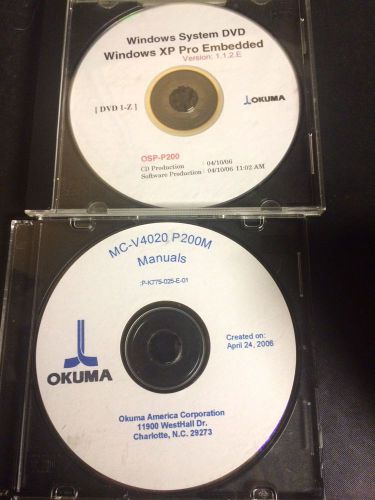

Okuma MC-V4020 P200M Manuals and Windows system Disc

CITIZEN VTF-112L Turning Holder

People who viewed this item also vieved

Jessop Steel Company Washington PA Vintage Booklet Tool-Die & Specialty Steels

Titanium Flat Tipped Dabber With Pewter Base Nails, XcentriX Designs XD USA

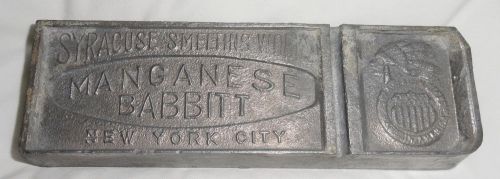

VINTAGE SYRACUSE SMELTING WORKS MANGANESE BABBITT NEW YORK CITY INDIAN HEAD

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies