US $255.00

Directions

Similar products from Stamping Machines & Embossers

ANTIQUE BRANDING IRON STAMP MARKING STAMPING TOOL C.H.SNYDER BARREL CRATE

NEW Black Ideal Custom WEDDING Bride & Groom Name & Date Seal Embosser Hand Held

Love Blak Ideal Custom WEDDING Bride & Groom Name & Date Seal Embosser Hand Held

Stylish Round Personalized Name and Date Wedding Pocket Embosser Shiny EZ-Seal

Round Custom Love is Sweet - Name and Date Wedding Pocket Embosser Shiny EZ-Seal

NEW OHIO OFFICIAL NOTARY Pocket Embosser Circular Layout Shiny EZ-Seal Hand Held

NEW With Love your name custom with Mask Embosser Circular Layout Shiny EZ-Seal

Hot Foil Stamping Water Soluble Photopolymer Plate Die Mold UV Gilded Version

Hot Foil Stamping Machine Emboss Invitation Business Card Letterpress Printing

New Manual Number Words Date Printing Machine for Bag,Paper,Film ect

Hot Foil Stamping Machine Wedding Gilding Printing DIY Embosser Business Card

NEW IMPRINT ORANGE G331-1NT 1000' x 3" HOT STAMP FOIL 1" CORE

Imprintor Professional Pad Imprinter System for Imprinted Promotional Products

UV Exposure Unit for Hot Foil Pad Printing TIMER, Double side

70 EMBOSSING MACHINE 1/7 INCH 1/10 INCH HEAVY DUTY STEEL MANUAL PVC CARD

70 EMBOSSING MACHINE HEAVY DUTY STEEL VIP CLUB CARD ADJUSTABLE KERNING POPULAR

Schmidt R-2513-MP-D1 Dovetail Straight Type Holder (Inv. 15336)

Pad Printing Plate Making Manual Pad Printer DIY Golf Ball Pen DIY Logo Transfer

Hot Stamping Foil Ribbon for Embossing and Printing Coders - BLK - 4.02" x 300m

People who viewed this item also vieved

200 Yellow Mesh - Aluminum Silk Screen

4 Color 4 Station Screen Printing Kit Flash Dryer Exposure Unit Squeegee Supply

18x18 Flash Dryer Silkscreen Equipment T-shirt Printing Curing Adjustable Height

4 Color 1 Station Screen Printing DIY Printer Flash Dryer Starter Supply 006981

NEJE 300mW Mini USB DIY Engraver Cutter Laser Engraving Cutting Machine F5

NEJE JZ-5 High Power Precision 500mW DIY Laser Box Engraving Machine Engraver

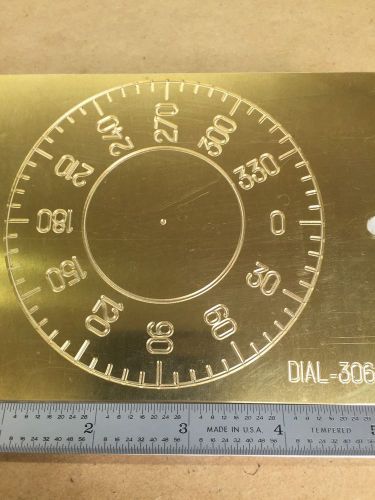

BRASS ENGRAVING PLATE FOR NEW HERMES FONT TRAY INSTRUMENT DIAL DEGREES CLOCK

Awards and Engraving Business - Roland EGX-30

A002 Direct to Garment Printer, Digital Printer

Dainippon Screen Mfg. Film Frame Duplicator P-637-GQ

garment pretreat machine for direct-to-garment printing

2014 DTG M2 / DIRECT TO GARMENT PRINTER / COLDESI

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies