US $6,450.00

| Condition | Used

:

An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “Includes power supply, RHF Console, Automatic Gas Console, PAC184 Torch Assembly, Cables, Leads.” |

Directions

Similar products from Plasma Cutting Equipment

2 Pin 24ft Plasma Cutting Torch CP242 for LOTOS LTP6000 FREE SHIPPING

3 Pin CNC Plasma Cutting Torch CC02 for LOTOS LTP6000 FREE SHIPPING

C1517 Plasma Electrode Nozzle 1369 Fit Cebora CP160 HP100 MP100 CB100 CB150,20PK

C1402 Plasma Electrode Fit Cebora P70 CP-70 and Trafimet CB70 PR0063,10PK

C1395 Plasma Nozzle,Long Long Life Fit Cebora Prof P50 CP50 P70 CP70 Torch,10PK

SIMADRE 7-PIN HIGH QUALITY PILOT ARC PLASMA CUTTING TORCH for 520DP

SIMADRE HIGH QUALITY P-80 PILOT ARC PLASMA CUTTING TORCH w WHEEL for 80SP

C1308 Plasma Nozzle Fit CEBORA P70 CP-70 Torch,10PK

SIMADRE HIGH QUALITY 7-PRONG PILOT ARC CUTTING TORCH for 520DP

SIMADRE HIGH QUALITY 2-PRONG P-80 PILOT ARC CUTTING TORCH w WHEEL for 80SP

220816 Nozzle for Hypertherm PowerMax, 1 Pack of 5pc, LAST LOT

220993 Nozzle for Hypertherm PowerMax, 1 Pack of 5pc, LAST LOT

Hypertherm Model 220629 400 Amp Electrode For HPR400 Plasma Torch

Plasma Nozzle 020611 100 AMP Fits Hypertherm Pack Of 3

CAL Electric Plasma Cutter CUT60D 60AMP New Inverter Dual Voltage Warranty

Plasma Cutting Castle Shield Cap 020335 Fits Hypertherm Max-100

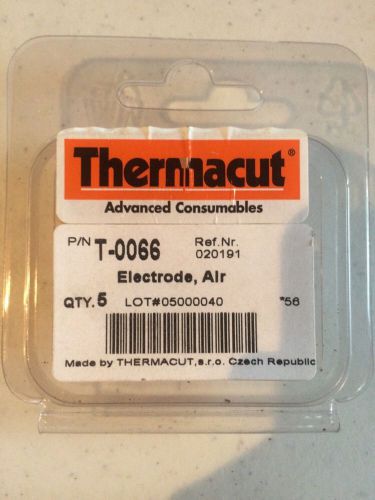

Thermacut T-0066 Welding Air Electode 5-pc

Thermacut Consumable, Part # T-0063, Nozzle 100 Amp Pkg Of 3

People who viewed this item also vieved

Lincoln Tig/Stick Welder Square Wave 355

Digital Display IGBT 200A ARC Welding Machine DC Inverter Welder MMA ZX7 200 AMP

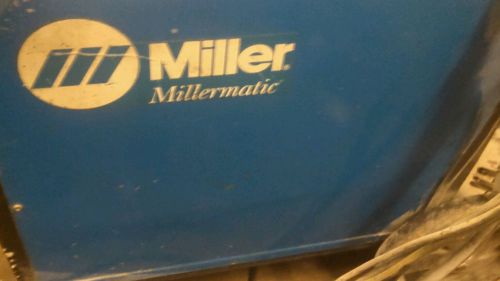

(1) Used Miller Millermatic 185 Wire Feed Welder aluminum spool gun

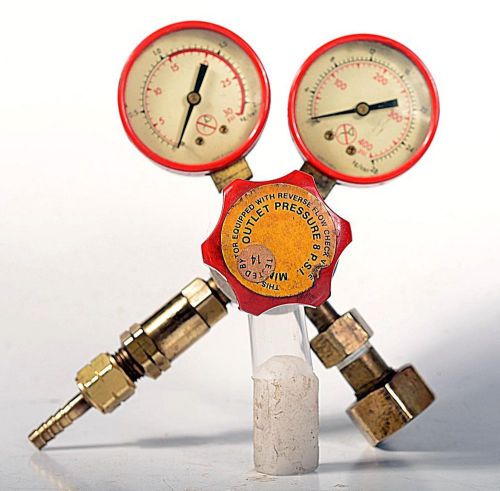

Tescom H1944A-200 Pressure Reducing Regulator. 400 PSIG In 30 Out with Gauges

BUGO BRAND TRACK CUTTING MACHINE W/TORCH & TRACK COMPLETE GOOD CONDITION

KOIKE IK-12 MAX II TRACK CUTTING MACHINE W/TORCH & TRACK COMPLETE GOOD CONDITION

VICTOR BRAND BEVEL CUTTING HEAD ATTACHMENT BHA

Welder Skull Hard Hat Decal mig tig arc rod torch welding hard hat skull sticker

Tweco 600 Amp Welding Ground Clamp GC-600-50 9210-1150

ABICOR BINZEL 960.9012 ROBOWH-WC 12' CUS EU WB1 w/ robo vts 500ts (Inv.34940)

Window Cleaner Crossbone Decal - window squeegee t bar rappel rack skull sticker

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies