US $7400

Directions

Similar products from Professional Sawing Equipment

POWERMATIC MODEL 66 Table Saw 3 groove electric motor belt pulley 1" sheave

Grizzly Cabinet Table Saw 3HP 220V Shop Fox 10" left tilt long rails mobile base

LEICHTUNG ANTI-KICK BACK DEVICE, 100263

JET VBS - 18MW 3/4 HP 1PH 115/230V Metal/Wood Vertical Band Saw

Delta 50-C Radial Arm Saw 14", 3 ph, 3 hp

Felder G300 Edgebander 230V 60HZ 3,2 S1 KW 14A 3PH

SCMI Mod.SL16WA Sliding Table Saw

Whrilwind 212L 18'' Upcut Saw NO RESERVE

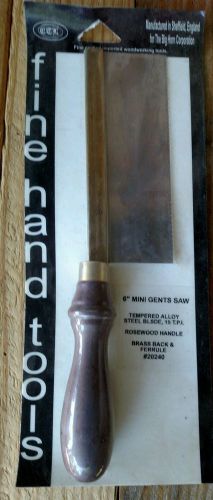

Big Horn 20240 6 Inch Mini Gents Saw

Olson Band Saw Blade 3/16" Wide x 80" Long, 10 TPI

MA S DELTA UNISAW X5 10” 3 HP 1 PH 220 VOLTS 52” BIESEMEYER FENCE EXCELLENT

Radial Arm Skilsaw Model 345 15" Blade Arm Travels 23" X-Cut 18" Table 148"x23"

Insert for 10" Delta Tilting Top Table Saw 12" X 3 3/4" cast#1163,delta#TCS-207

DELTA ROCKWELL UNISAW FENCE FOR 1-3/8" MOUNT BARS

Grizzly G0493 Siding Table Saw 10HP 220/440V 3

People who viewed this item also vieved

Rockwell Router model 4620 Type1 120 volt 3.5 amp 5710-20

Morso Guillotine Framing Machine with blades

355 CNC 3d Relief Model STL for Router 3 axis Engraver Mill ArtCam Cut3D

349 CNC 3d Relief Model STL for Router 3 axis Engraver Mill ArtCam Cut3D

342 CNC 3d Relief Model STL for Router 3 axis Engraver Mill ArtCam Cut3D

Dynabrade 52294 Right Angle Grinder - .7hp NEW

Penn state 6" belt and " Disc sander/finishing machine make offer

General 15" Drill Press, Model 34-01, Made in Canada

Woodpeckers Precision Woodworking Tools WPDPPACK1 Drill Press Table, 1-Pack

Shaper or Router Fence ?? Lester-1 29L-254 from Drill Press ?? Alloy/Aluminum

DELTA 12" WOOD LATHE TAIL STOCK

15x54 Challanger Lathe With DRO And VFD

Lathe, Wood Lathe, Metal Lathe, Seneca Lathe

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies