US $5600

Directions

Similar products from Rotary Cutters & Paper Trimmers

SHARP! 35.5" LENGTH GUILLOTINE PAPER CUTTER TRIMMER BLADE 3" WIDTH x 1/4"

Swingline SmartCut 15 Inch Replacement Cutting Mat for Commercial Series, 2 New

VINTAGE INDUSTRIAL!! Paper Cutter Trimmer Arts Crafts Tower 12" Photo Scrapbook

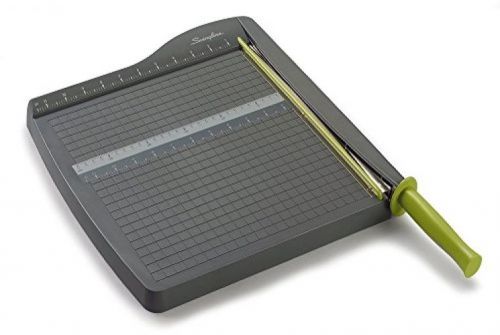

Swingline Paper Trimmer / Cutter, Guillotine, 12 Cut Length, 10 Sheet Capacity,

Vintage 1987 Saunders Rotatrim Mastercut 2 Paper Trimmer 17" Made in England

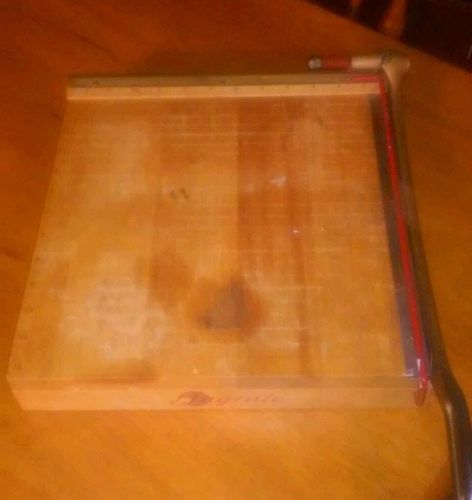

VINTAGE INGENTO WOOD PAPER CUTTER #4 IDEAL SCHOOL MAPLE WOOD No 4 EUC

Wohlenberg/Visolux Light Curtain, Light Screen, Safety Beams

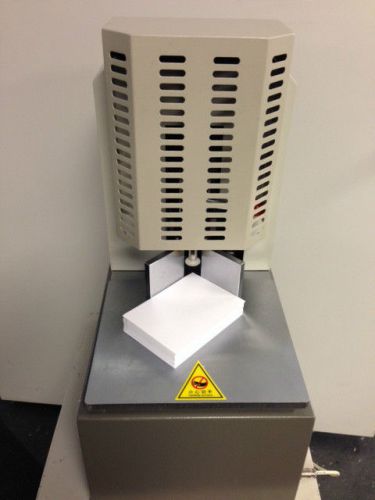

Electrical Round Cornering Machine with 7 Built in dies Corner Rounder Cutter

Westcott Trimair Wood Guillotine Paper Trimmer - Cuts 30sheet - 12" Cutting

X-Acto 12" Paper Trimmer, Black, 10 Sheet Capacity

2015 DUPLO DOCUCUTTER 490 PRO HYDRAULIC PROGRAMMMABLE DOCUMENT CUTTER

Swingline Paper Trimmer / Cutter ClassicCut Ingento 30 Inch Maple Guillotine

Dahle 556 37" Cut Professional Large Format Rotary Paper Trimmer

Archival Methods Acid Free Foamboard, 17x25" 1/8 Thick, Color: White,(Pack 10)

Archival Methods Mat Board,16x20in,4 Ply,Pearl Wht,25Pk #97408

Archival Methods Mat Board, 11x14in, Pearl White, 25Pk #97203

Olfa ABB for OL-180/OL-SVR1/OL-300/OL-A, 50 Pack #OR-AB50B

Archival Methods Acid Free Foamboard, 8x10" 1/8 Thick, Color: White,(Package 10)

Archival Methods Mat Board, 20x24in, Pearl White, 25Pk #97209

Archival Methods Mat Board, 8.5x11", Pearl White,25Pk #97405

People who viewed this item also vieved

Clear File Uta no Prince-sama Camus Sweet Ascii Media Works Japan

Clear File Shingeki no Kyojin Childhood Friends ver. Kotobukiya Clear File Set

Clear File Shingeki no Kyojin Movic IP954

Pre-owned LaserMax 568 Feeder, used sheet feeder

15 - S J Paper Expanding Classification Folders 2 Dividers Legal Green - S61401

2x Rolls 25" x (1050+') 1.7 mil Hot Laminating Roll Film 3" core PET polyester

TWO Rolls 12" x 1000' 5 mil Glossy Laminating Roll Film 3" core PET polyester

Lassco Wizer W100 Number-Rite Numbering Machine - New & Free S/H

Southern Stamp & Stencil Numbering Machine

Brand New Heavy Duty A3 Pouch Laminator / laminating machine (6 rollers, fast)

Brand New Heavy Duty A3 Pouch Laminator / Laminating machine (All metal Build)

Hand Marbled Paper 48x67cm 19x26in Bookbinding SERIES, Handmarmorpapier Einband

Rhin-O-Tuff ONYX HD8000 Binding Module With New Wire Hanger – NEW!

Challenge MS 5 paper drill with 3 drilling heads 3 Hole Paper Drill late model

Corner Rounder Cutter - Includes 4 Dies - 1/8" 1/4" 3/8" Straight - Heavy Duty

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies