US $3100

Directions

Similar products from Espresso Machines & Spare Parts

Sirai Pressure Switch for Nuova Simonelli part 09200006

motion ts delicom pc board p/n #1777 71.31.63

BUNN Lever-Action Commercial Airpot Air pot 2.2 Liter stainless

Rio Espresso maker machine commercial, with accessories and manual

ULKA EAX5- EX5- 120V 52W NSF VIBRATION PUMP ESPRESSO CAPPUCCINO

Mokaroma Commercial Espresso Cappuccino Machine GREAT DEAL!!!

1 Group Nuova Simonelli MAC Commercial Espresso Machine !!!

Cecilware Vae2 Venezia Espresso Machine

RANCILIO Copper Gold Plated Vintage Espresso Cappuccino Machine Rare

SAECO SG200 Gourmet Coffee / Expresso / Cappuccino Machine (commercial grade)

Astoria Jada Akc Commercial Espresso Machine

Water Softener USED "LID & SUPPORT" for DVA 8Lt. Ion Exchange Softener

GREAT DEAL ON 2 group VFA Commercial Espresso Machine!

nespresso gemini comercial machine

thermoplan 72.70.64 waterpump ts assy

Astoria Divina SAE-2 Espresso Machine - Red

Rancilio Classe 8 DE Single group Fully Automatic Espresso Machine - iSTEAM -

Brasilia espresso machine automatic single group powers on parts machine as is

SAECO SG 200e EUROPEAN ESPRESSO/CAPPUCCINO/COFFEE MACHINE

People who viewed this item also vieved

BUNN COMMERCIAL 1.5 GAL MODEL TF SERVER DIGITAL GAUGE SERVER W/ BASE

BUNN COMMERCIAL BREW MACHINE WITH WARMERS CW SERIES

BUNN SINGLE BURNER SATELLITE COFFEE POT WARMER MODEL WX1 WORKS GREAT

Bubble Tea Automatic Electric Cup Sealing Machine Sealer Boba Coffee LCD

BLOOMFIELD STAINLESS STEEL TEA DISPENSER 5 GAL.

La Pavoni Boiler Release Valve for Europiccola and Professional

Aladdin 5 Pk Reusable BPA Free Plastic 16oz. To-Go Cups w/Travel Lids, Asst .

GMCW PRECISIONBREW 1-1/2 GAL. STAINLESS STEEL COFFEE SHUTTLE - CS-LL

Daily Chef Food Service Coffee Pot 2 Pack 60oz.

used MAZZER Major Electronic Espresso Coffee Grinder Expresso

Bunn G92 HD Dual Hopper Portion Control Coffee Bean Grinder 24250-0000

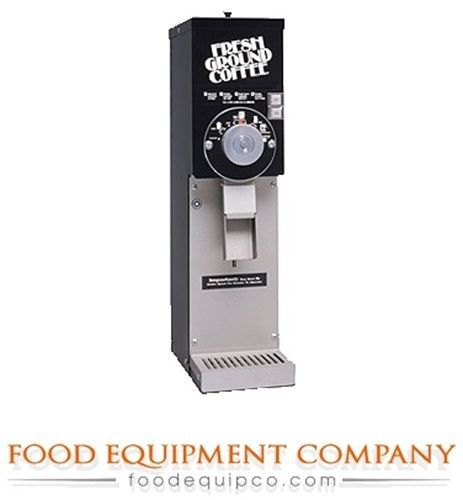

Grindmaster 890T Coffee Grinder heavy-duty 3-lbs Hopper Capacity

Jura Impressa F8 Bean to Cup Coffee Machine Home Kitchen Appliance New

Coffee Airpot Swivel Base, Great condition set of 4

Six (6) Individual Assorted Travel Creamer Sweetener Stirrer Packs

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies