US $3900

Directions

Similar products from Vacuum Pumps & Pump Kits

ULVAC Oil Rotary Vacuum Pump D 950

Varian 2.75" CF High Vacuum Electric Plug Feedthrough Flange

NASH VACUUM PUMP - REBUILT CL-1002 Cast Iron

Varian 971-1008 Dual Range Ionization Gauge

Acme cryogenics evac valve caps (3)&rebuild kit

* NEW * Huntington 4 1/2" Blank Flange MDC Varian 4.5" vacuum conflat

Varian Dual Range Ionization Gauge Model 971-0014

HELIX CTI Cryo-Torr 8 Cryogenics High Vacuum Pump 8033168

FASCO VACUUM PUMP, AIR & WATER PUMP, TESTED, WORKS FINE

Airtech international vacuum guage

Vacuum Generators Ltd. Residual Gas Analyzer Probe RGA Sensor

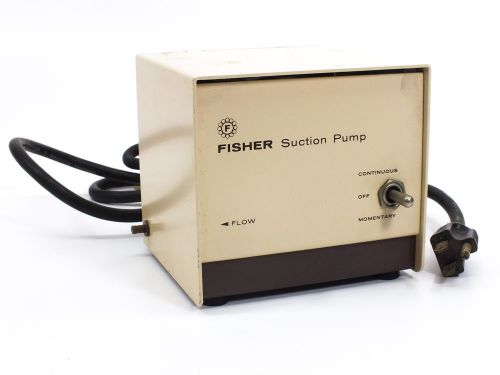

Fisher Suction Pump Momentary / Continuous *AS-IS / FOR PARTS* Bad Tubing (56A)

Edwards Single Phase High Vacuum Pump 115/230 VAC *AS-IS* MOTOR SEIZED (E2M2)

Leybold Trivac Rotary Vane Vacuum Pump D1.6B

NaceCare WV900 Wet Vacuum with C2 Front Mount Squeegee Kit, 12 Gallon Capacity,

ILMVAC GmbH Type 109030-13 LABORATORY VACUUM PUMP condensor Evaporation system

GAST 4LCB-10-M450X Piston Air Compressor/Vacuum Pump 1/2HP/Hookah Scuba

Dayton Speedaire Model 4Z024 110/115V Comperssor Vacuum Pump

People who viewed this item also vieved

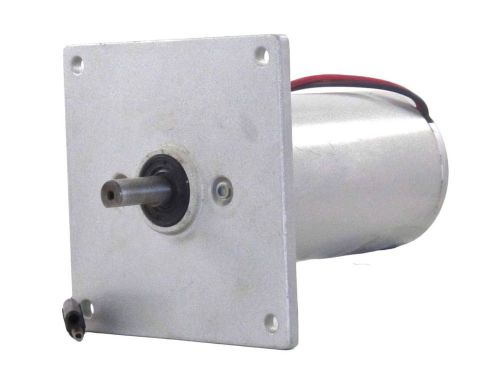

Baldor M16B 91751373-03 Industrial Motor New

NEW ELECTRIC PUMP MOTOR HAHN HYDRAULICS MMQ4001A 46-142 46-2363 BI-DIRECTIONAL

BUYERS SALT SPREADER MOTOR BP801-005B BPC-12 300-5414 300-5693 BP801-0058

NEW MOTOR SUBURBANITE WESTERN SNOW PLOW 27753 2- TERMINAL 2 BOLT 3-9 POSITION

Goulds Submersible Effluent Pump #WE1534HH 2" Outlet 1.5 HP 460V 3 Phase (NIB)

SEARS 1/4 hp sump pump BRAND NEW, STILL IN BOX. UN OPENED

Simer Submersible Well Pump 4in. 2850G

Zoeller D284 Automatic Submersible Sewage Pump, 1 HP, 230V, 1 Ph, 3" NPT (74B)

Red Lion 1/2 HP Deep Well Submersible Pump (2-Wire 230V)

Goulds 3196 4x6x17 XLT-X Imp. Size 15.5" Back Pullout NO PACKING GLAND (fic196)

Cast Iron Submersible Effluent Sewage Pump 115V 2"npt Discharge

Little Giant EFFluent Submersible Sewage Pump 2"npt Discharge Float Switch

oms 200 Sauer Danfoss 392B 151f5104-3 hydraulic pump shaft and pin

oms 200 Sauer Danfoss 362A 151f5104-3 hydraulic pump shaft and pin

CESSENA HYDRAULIC PUMP 24386RAM NSN 4320-00-165-4235 NEW

NEW KSB 414191 2-7/8X2-3/8X1IN SPACER SLEEVE PUMP STEEL REPLACEMENT PART D329287

NEW KSB 414183 60X73X60MM PUMP SLEEVE STEEL REPLACEMENT PART D329284

ALFA LAVAL BRPX 213 CENTRIFUGAL DISC STAINLESS REPLACEMENT PART D423786

NEW KSB 414182 58X70X86MM SLEEVE STEEL REPLACEMENT PART D329276

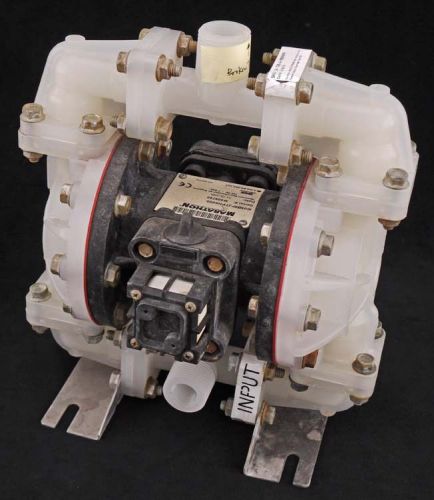

Marathon M05B2P2TPNS000 Non-Metallic Air-Powered Double Diaphragm Pump M05

Dayton 1P879 Pump w/ 9K861C Motor

BROWN&SHARPE ROTARY GEARED PUMP 713-3-9

12 volt fuel transfer pump GASBOY model 60, 61, fill it rite, gas & diesel

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies