US $4300

Directions

Similar products from Sealing Machines & Bag Closers

Automation Packaging Inc.(API) Shrink Bundler with Tunnel Stainless Steel

12" Heat sealing machine Impulse Sealer seal machine poly tubing bag kit

USED PFS-300 IMPULSE SEALER FOR PP/PE BAGS

New Hand Held Heat sealing machine Snack Plastic Bag Sealer Personal Travel Kit

VERY NICE ITALDIBIPACK 28" LONG SHRINK TUNNEL 5 KW MODEL ES 5040 2N - 220/380 V

VERY NICE DEM 8 KW SHRINK TUNNEL SP4521MAEDPA TYPE

GULF BEARING S-3507 2RS . NIB. SB7

NDH BEARING DELCO 1+3205 BALL BEARING . NIB. SB7

New Heat Mini Portable Handheld Sealing Machine Instand Manual Seal Home Use

Mini Portable Plastic Bag Sealing Tool Home Kitchen Handheld Impulse Sealer

New Mini Portable Handheld Sealing Machine Heat Tool Plastic Bag Home Use

TRW MRC BEARING 304SG AOEC-1. NIB. SB7

SNR A06291 BEARING 6308. NIB. SB7

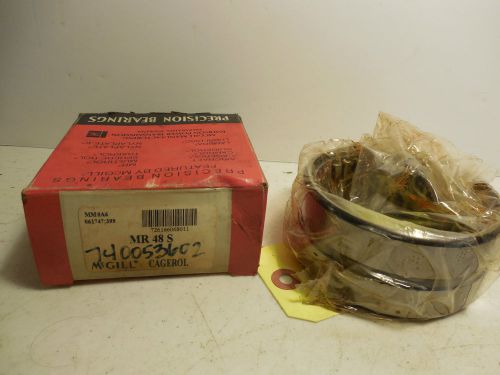

MCGILL PRECISION BEARINGS MR48S. NIB. SB7

People who viewed this item also vieved

Talon Massm an Dual Clamp Horizonta Fill & Seal Pouch Packager for Soap Product

stretch wrap machine, pallet wrapper, stretch wrapper

SEMI AUTOMATIC PALLET STRETCH WRAPPER MACHINE

Industrial spring loaded tables for parts.

DZ500-2D Single- Vacuum Packaging Machine

Signode VXM-2000-Z Pneumatic Tension-Weld Strapping Tool

Lot of 5 Signode Black Plastic Strapping 7/16" 200ft HD723B Part NO: 2X1677G

WAREHOUSE SHIPPING MIP 1800 BAND TOOL Pistol Grip Insulation Banders

Joinpack ES-102A Semi-auto Strapping Machine Machine # 102111230 (2002)

JOINPACK Plastic Strapping Machine Model AS102A, F/Parts or Repair Untested Used

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies