US $85.00

| Condition | Used

:

An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

|

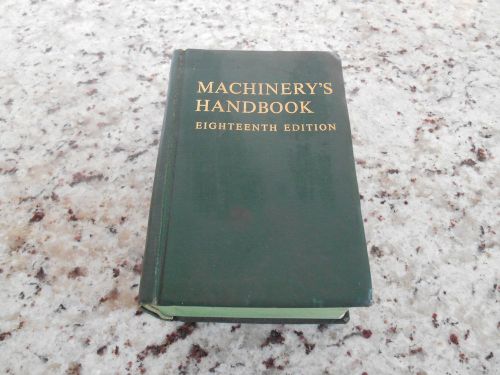

| Seller Notes | “This book is an ORIGINAL, not a reproduction. It is in very good condition: the covers are soiled and slightly edgeworn, especially at the corners. There is a one inch tear at the top spine, back. The pages are clean and free of marks and underlining. The binding is not quite tight, but nearly so, with no cracks, and the flyleaves are fully intact and bound. There is no evidence of yellowing or foxing.” |

Directions

Similar products from Instruction Manuals for Metal Cutting

Myford 1A Hydraulic Copying Lathe Operation, Maintenance & Parts Manuals

DoAll C-6 Metal Cutting Band Saw Operation, Maintenance & Parts Manual

DI-ACRO 12 Ton Press Brake Instructions & Parts Manual

DI-ACRO 16-24 Press Brake Instructions & Parts Manual

Mori Seiki Operate Manual SL-1 CNC Lathe w/Mori Yasnac (17977)

How to Design and Build Centrifugal Fans for the Home Shop, by Dave Gingery

Deckel SO Cutter Grinder Instruction Manual - Latest Edition

The Mechanic's Friend: A Collection of Receipts and Practical Suggestions (1875)

Mazak H15 H-15 H15B Horizontal Machining Center Maintenance Manual Mazatrol M2

Mazak H15 H-15 H15B Horizontal Machining Center Supplement ATC Hydraulic

D.H. Stoll Company, Catalog of Sheet Metal Working Machinery - 1910s? - ORIGINAL

1908 Waterbury Farrel Foundry and Machine Co. Catalogue - ORIGINAL

Stewart Industrial Furnaces Catalogue No. 85 - 1925 - ORIGINAL

Fuji Electric Frenic 5000MS5 Instruction Manual (Inv.30036)

Fanuc Series 16 And 18 Parameter Manual (Inv.30037)

Fanuc Series 16 And 18 Operator's Manual (Inv.30038)

Petrol-driven Motor Cars (1909) - reprint

Reid Instruction & Parts Manual Model 618 HA Grinder (17984)

1920 Catalog—Toledo Machine & Tool Co—Punching and Shearing Presses - ORIGINAL

Lathe and Planer Tools, Machinery's Reference Book No. 7 - 1908 - Reprint

People who viewed this item also vieved

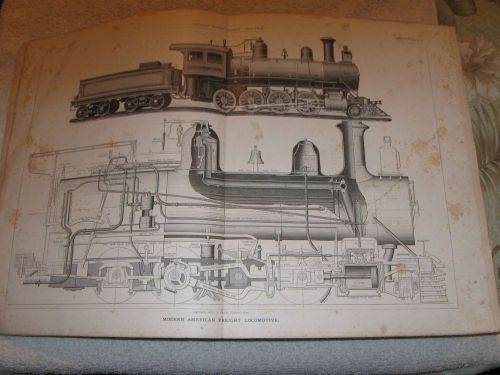

Modern Machine Shop Practice 1887 By Joshua Rose 3000 Engravings Voulue 1

MACHINERYS HANDBOOK , 18 TH EDITION , 1968

Cincinnati Milacron Horizontal Machining Center Manual

Cincinnati Milacron Technical Manual

VINTAGE 1940's ATLAS PRESS Co LATHE DRILL PRESS MILLING MACHINE PARTS PRICE LIST

Thermal dynamics mauals. 5 booklet LOT

Basic Sheet Metal Practice Book

Procedure Handbook of Arc Welding Design & Practice Lincoln Electric Co 1945 8th

Best Of American Machinist January-June 1909 Lost Technology Series

Best Of American Machinist July-December 1909 Lost Technology Series

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies