US $23.00

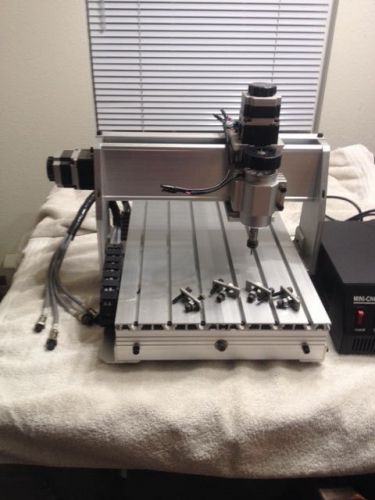

| Condition | New other (see details)

:

A new, unused item with absolutely no signs of wear. The item may be missing the original packaging, or in the original packaging but not sealed. The item may be a factory second or a new, unused item with defects. See the seller’s listing for full details and description of any imperfections.

|

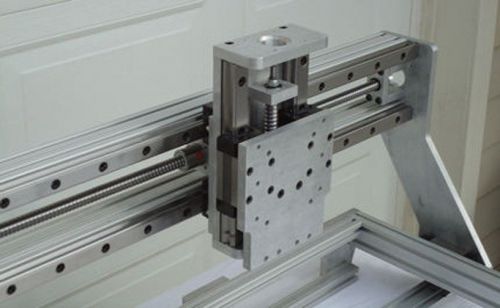

| Seller Notes | “Auction is for the PLANS to construct the machine. It is NOT for the machine or any parts. This auction is for the CONSTRUCTION MANUAL to build this machine (drawings, bill of materials, assembly instructions, and supplier list.)” |

Directions

Similar products from Professional Router Machines

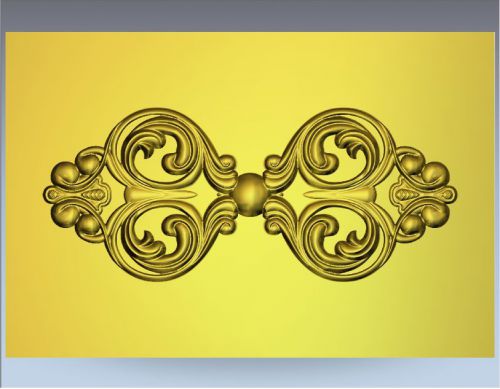

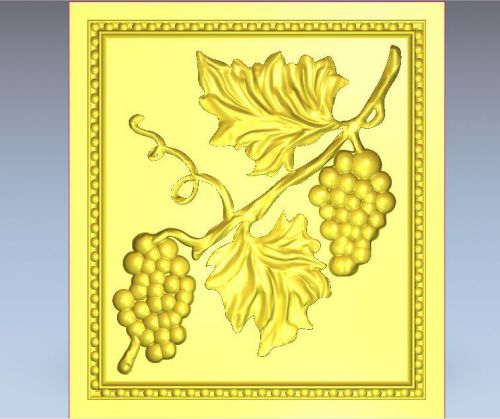

beautiful artcam 3D cnc decor 3D model relief Stl Rlf For CNC 43

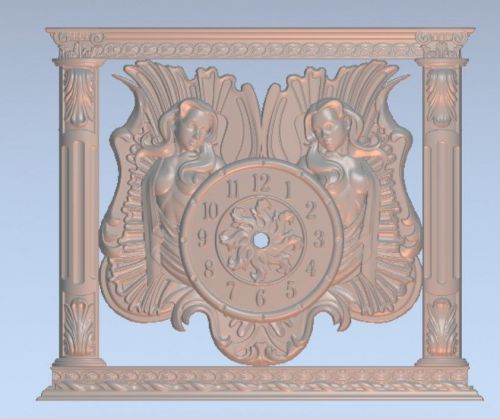

Mental clocks nice sexy girls full version #4 3d STL file by miccot

Mental clocks nice sexy girls full version #2 3d STL file by miccot

Mental clocks nice sexy girls full version #3 3d STL file by miccot

beautiful artcam cnc decor 3D model relief Stl Rlf For CNC 5 vine 25

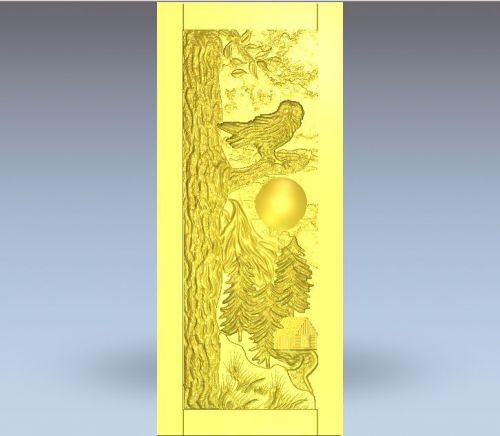

3d STL Model for CNC Router Machine Aspire Cut3d Bas Relief Artcam 19

beautiful artcam 3D cnc door decor 3D model relief Stl Rlf For CNC 3

3d STL Model for CNC Router Machine Aspire Cut3d Bas Relief Artcam 9

beautiful 3d STL Model for CNC Router Machine Aspire Cut3d Bas Relief Artcam

beautiful artcam cnc decor 3D model relief Stl Rlf For CNC 77 45

Porter Cable 7518 Variable Speed Router/Betterley Coving System with 2 Bits

CNC Milling Machine For Routing Engraving Drilling 3 Axis , W/Control Box.

CNC 3d Relief Model STL for Router 3 axis Engraver ArtCam ax mermaid

Nautical CNC Wall Art for Plasma Cutter / Router Table / Laser EPS & DXF

1319 CNC 3d Relief Model STL for Router Engraver Mill Woodworking 3D printer

345 CNC 3d Relief Model STL for Router Engraver Mill Woodworking 3D printer

beautiful 3d STL Model for CNC Router Machine Aspire Cut3d Bas Relief Artcam 1

CNC Mill Router Kits Engrave Plasma Travel 24"x24" Commercial Milling

ISEL AUTOMATION MILLING MACHINE router CNC station automatic engraver davinci

PORTER CABLE ROUTER MODEL 6912 W/ 2- 1001 bases

People who viewed this item also vieved

NEW Makita 194368-5 Guide Rail, 55-Inch/1.4M For Use With SP6000 Saw

Powermatic 141 14" Vertical Band Saw

Delta RT-40 Heavy Duty Table Saw. 7.5hp/3ph with Delta Unisaw Fence

Nice! Porter Cable 10" Wide Vertical Belt Sander with Tilt Table. Made in USA

Central Machinery C112 Drill Press 5 Speed Bench Table Top 5/8" Chuck Heavy Duty

Rockwell Delta 6" # 31-520 Sander Platen -BS-205

Rockwell Delta 6" Belt Sander Series 31-520 Factory Original Belt Guard

Delta 14" bandsaw Upper Wheel bearings Older style (2)

Oliver 2018.002 Woodworking Lathe

36" Craftsman Wood Lathe On Stand With Tools

Delta 930 Lathe Tool Rest Banjo DDL171 DDL-171

Delta Wood Lathe Steady Tool Rest DDL12 Cat 692 12" Wide 1" tool post rest

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies