US $25,000.00

| Condition | Seller refurbished

:

An item that has been restored to working order by the eBay seller or a third party not approved by the manufacturer. This means the item has been inspected, cleaned, and repaired to full working order and is in excellent condition. This item may or may not be in original packaging. See the seller’s listing for full details.

|

| Seller Notes | “Fully reconditioned and upgraded MPM / Speedline UP-1500 / Accuflex fully automatic Screen Printer with 2D post print, Automatic Support Pin Placement System, UltraWiper Under-Stencil Cleaning System, Rheometric Pump Print Head Systems, Integrated Post Print Analysis, and Triple Track Conveyor System. This machine is equipped with the productivity plus configuration.” |

Directions

Similar products from Printed Circuit Boards Assembly Tools

SMT Line MPM UP2000 Hie Printer (2) Universal GSM2 Vitronics 1030N Reflow Oven

2 Contact Systems Dip Lead Former CS-470 SMT PCB

Static Discharge Grounding Reel Model No:EDR20

ACE KISS 103 Selective soldering system 2007 2 pots solder machine

1 pc of FORCE Computers SYS68K CPU-33B/4 S/no. 648B106G0311

Electrovert EPK Plus 400/F Flow Duct W/Vein

Mydata MY12 Pick and Place Machine PC Board Placement SMT PCB Hydra Head

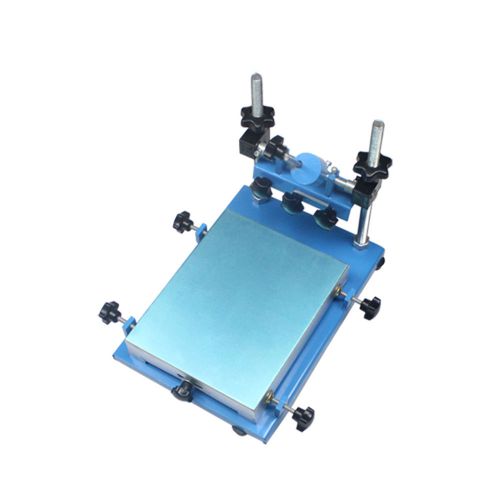

Good Quality SMT PCB Manual Stencil Printer Solder Paste Silk Screen Printer

HOZAN Tool Industrial CO.LTD. ESD PCB Rack F-33 Brand New Best Buy from Japan

HOZAN Tool Industrial CO.LTD. ESD PCB Rack F-32 Brand New Best Buy from Japan

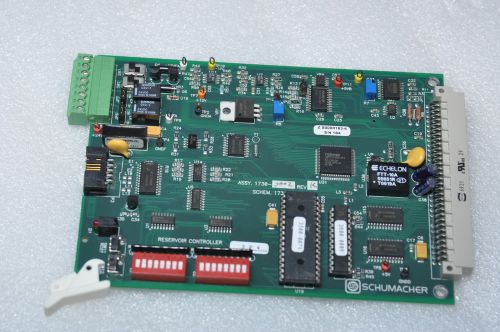

SCHUMACHER ASSY1730-3009 REV.H CONTROLLER BOARD

SCHUMACHER ASSY1730-3400 REV.H CONTROLLER BOARD

SCHUMACHER ASSY1730-3002 REV.K RESERVOIR CONTROLLER BOARD

SCHUMACHER ASSY1730-3014 REV.B CONTROLLER BOARD

Electrovert Electra 24 Point I/O Board Part# 6-1860-185-01-1 Rev C (Refurbished)

MPM/Speedline Magnetic Support Blocks (Lot of 2)

People who viewed this item also vieved

2X-90X Zoom Stereo Microscope w/ 10X 20X Eyepieces+0.3X Barlow Lens+Boom Stand

20X-40X-80X Stereo Binocular Microscope+60 LED Light Soldered Point Inspection

6.7X-45X Zoom Stereo Trinocular Microscope with High Pillar Dual-bar Boom Stand

Portable Flexible Borescope HF9 1350

NEW SEALED Lam Research 716-044668-430-A Ring Semiconductor Part

NEW SEALED Lam Research 716-044668-002-C Ring Semiconductor Part

Lam Research 839-015480-010-C Electrode Semiconductor Part

NEW SEALED Lam Research 716-800330-063-C Insulator Bottom ESC Tapped

Vessel Static Eraser Bar No B-60 / lot of 3

DAIKIN, DFS505TE1A MMH500 Ultra-high Performance Fluorocarbon Polymer Air Filter

Desco 60457 Chargebuster High Output Benchtop Air Ionizer Antistatic Blower

Ajax oxygen bleach powder 5-21oz cans

NEW EMPAK ULTRAPAK 100MM CASSETTE HOLDER WAFER TRANSFER PORTABLE CASE

NEW EMPAK ULTRAPAK 150mm CASSETTE HOLDER WAFER TRANSFER PORTABLE CASE

JEOL JWS-8755S CD-SEM (Defect Review)

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies