US $3500

Directions

Similar products from Cleanroom Gear & Expendables

NEW SIMCO IONIZER model 4003367 (T)

Simco Top Gun Sidekick Air Gun Ionizer

1084 Foamtec HT1206 Contamination Control Swabs, Foam-over-Cotton Head

PINION CORPORATION VOYAGER WORKSTAT 2000 IONIZING BLOWER

Semtronics ZVI-5100 Zero Volt Benchtop Ionizer

Ion Systems Nilstat 5285E AeroBar Bipolar Ionizer Static Control System 44 1/2"

Ion Systems Nilstat 5285E AeroBar Ionizer Static Control System 22 " W/ Brackets

** CONTROLLED STATIC AIR IONIZER MODEL 60410

Sealed PALL 6101 series GLF6101VF114 Gas Filter filtration semiconductor NOS

Howard LM0008 Lemon Oil Wood Polish, 8-Ounce

Cleanroom. Class 10,000. Beautiful. Available Now!

Germanium Selenium Sputter Target, 2" x 3mm, bonded, by ACI Alloys

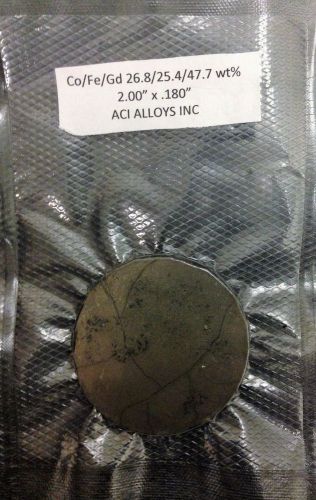

Cobalt Iron Gadolinium Sputter Target, 2" x 4.5mm, by ACI Alloys

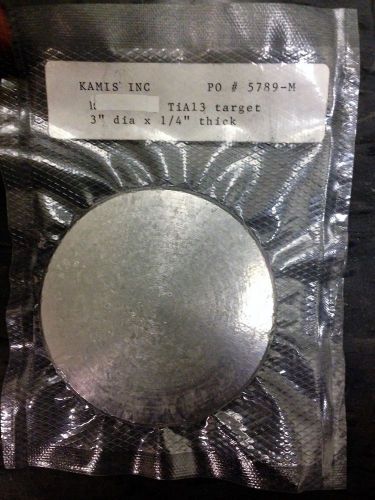

TiAl3 Sputter Target, 3" x 1/4", by Kamis

Cobalt Tantalum Zirconium Sputter Target, 2" x 3mm, by ACI Alloys

Titanium Oxide/Niobium Oxide Sputter Target, 2" x 3mm, by SCM

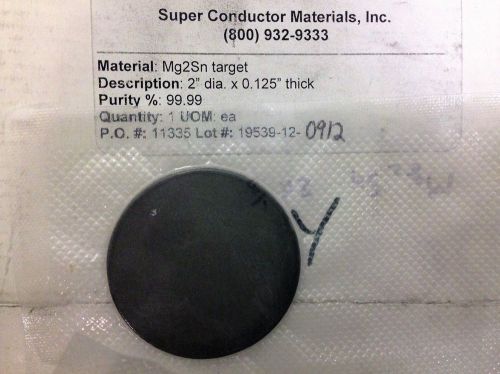

Magnesium Tin Sputter Target, 2" x 3mm, by SCM

Niobium Titanium Sputter Target, 2" x 1/4", by ACI Alloys

Copper Nickel Sputter Target, 2" x 3mm, by ACI Alloys

New AAF Astrocel 1 NUCLEAR GRADE Clean Room HEPA Air Filter 24x24x11.5 1000CFM

People who viewed this item also vieved

Varian, Agilent GLASS ION GAUGE, 572, p/n K7360302

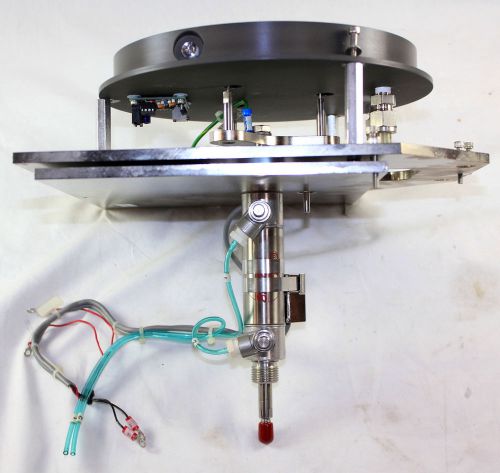

ASML, ASSY CHILL PLATE PROXIMITY, p/n 99-38369-02

Entegris, POZZETTA / TOPPAN RETICLE SHIPPING CASSETTE, p/n 4002-3175-01

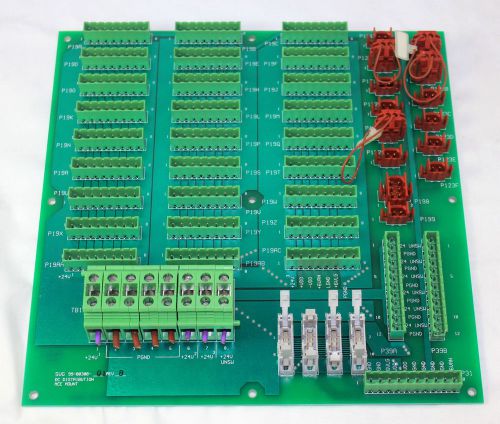

ASML PC Board - DC DISTRIBUTION MCE MOUNT, p/n 99-80308-01

MyData Automation VMF30 Feeder Magazine

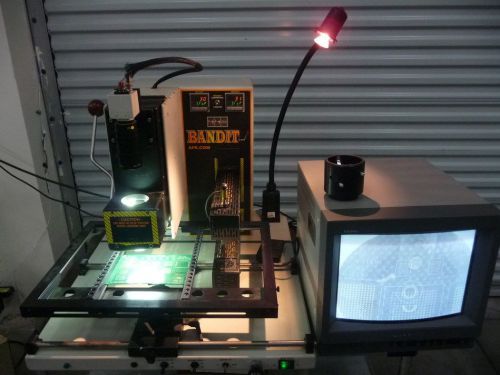

APE Bandit SMD-7500-1000 Split Vision Rework System

AMAT 0010-25974 Gear Assembly ,Brush Modul

AMAT 0150-03345 CABLE ASSY, HR2, DRIVER-MOTOR POWER, MIR

AMAT 0021-22064 COVER RING TTN 300MM PVD

AMAT 0010-08114 ASSY, GRIPPER, UPGRADE, 200 MM MESA, NEW

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies