US $13000

| Condition | Seller refurbished

:

An item that has been restored to working order by the eBay seller or a third party not approved by the manufacturer. This means the item has been inspected, cleaned, and repaired to full working order and is in excellent condition. This item may or may not be in original packaging. See the seller’s listing for full details.

|

| Seller Notes | “If interested in this drill pointer, please take the time to read through description. We know our machines very well and give very detailed information.” |

Directions

Similar products from Toold for Grinding Machines

KO LEE B7042 SENSITIVE WORKHEAD

Norton 3X High Performance Paper Abrasive Disc A975 10-Pack NIB

Mitsui Msg-200mh High Precision Surface Grinder Roller Bearing Table 6"x12" Mag

Norton 10 x 36 CTU Plain O.D. Grinder

No. 13 Brown & Sharp Universal and Tool Grinder

Surface Grinder Brown & Sharpe Micromaster 510 Hand Opp Roller Tble W5x10 Chuck

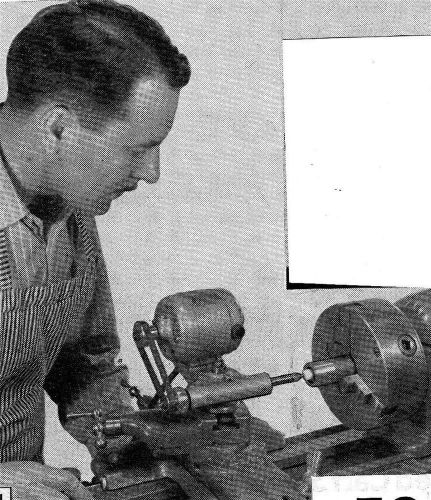

Tool Post Grinding For The Beginner How To Use Tool-Post Grinder Machining Turn

ADJUSTABLE JIG FIXTURE STAND CASTING POSSIBLE CINCINNATI GRINDER PART ACCESSORY

OD OUTER DIAMETER GRINDER WHEEL DRESSER JIG FIXTURE MACHINIST TOOLING

LARGE CLAMP WORK HOLDING CASTING MACHINIST JIG FIXTURE TOOLING

1.320 X 3/8 BORE 1/16" KEYWAY PULLEY FROM BRYANT CENTER HOLE GRINDER CABINET

3.400 X 3/8 BORE 1/16" KEYWAY PULLEY FROM BRYANT CENTER HOLE GRINDER CABINET

2.200X 3/8 BORE 1/16" KEYWAY PULLEY FROM BRYANT CENTER HOLE GRINDER CABINET

BRYANT 51407 SPINDLE FOR CENTER HOLE GRINDER

J & S Fluidmotion Precision Angle Radius Wheel Dresser Machinist Surface Grinder

UNIVERSAL WORKHEAD / WORK HOLDING FIXTURE FOR TOOLING CUTTER GRINDER

People who viewed this item also vieved

WILLIAMS NO. T-0-L AND R CARBIDE TURNING TOOL HOLDER FOR METAL LATHE

NEW OLD STOCK NORTON ALUNDUM METAL LATHE TOOL POST GRINDER ID GRINDING WHEELS

PILE OF VALENITE CARBOLOY CNC CARBIDE INSERT METAL LATHE TOOL HOLDERS 1X1 SHANK

DECKEL FP2 Spiral/Helical Milling Attachment FVSp2

30NMTB X 8 tool holders Kennametal Erickson

GRS Gravermeister Engraver Model GG500

A6 Salamander Crucible gold refining, precious metal recovery, smelting casting

A4 Salamander Crucible gold refining, precious metal recovery, smelting casting

Burgmaster Turret Drill Press! 6 Position! Excellent

Heavy Duty Helicoil Insert Installer Tool THD624L Tool Keensert Install

Starrett 93A T Handle Tap Wrench /used /NICE

SUNNEN HONE MANDREL WITH ADAPTOR K5-155CH OG STK2411

Automatic Kwik Lok Machine and Brush

10pcs Type G20 HSS Deburring Replacement Slot Edge Cleaner Blades Shaviv #29053

PEXTO ROLLER 381-D 36" / ROPER WHITNEY DIACRO/TENNSMITH /NIAGRA NICE!

Countersink 9pcs. browntool Aviation tools Most peices are NEW

H&G STYLE DM 5/8" CAPACITY DIE HEAD W/ 3/4" SHANK

SUMITOMO CARBIDE INSERTS TNMC32NV AC815, 6 PIECES 012315M7

HARDINGE O.S. DAV 3/8" ROUND FEED FINGER 0123159

System 3R Adaptor Plate - FH35

System 3R 20 mm capacity table mounting chuck - FH34

2011 Belmont MX-236 ZNC EDM Sinker (#1412)

#9558: NEW Ellis 1800 Horizontal Bandsaw Fabrication Equipment

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies