US $3700

Directions

Similar products from Printed Circuit Boards Assembly Tools

Ban Seok TAD-200S TAD200S Dispensing Controller

A.P.E. SMD-1000 SMD1000 Chipmaster Rework System

EUROLOG Z80 EML/CPC8 Syslogic Datentechnik

Alphasem AG SYS 10/3-04 Alphasem AG Die Bonder

Lot 2pcs. Panduit 100-096-053 100096053

Matrox Pulsar 586-03, PCI Frame Grabber card as photo,

MyDATA Agilis Yellow 4.7MM feeder inserts - 8mm for LM8 M8 quantity of 10pcs

EXTEC Labpol Duo 8 Grinding/Polishing Polisher Machine -

Simco A300 Aerostat 300W Ionizer / Heater

Conveyor Technologies CC-.5-1-H-UL 1/2 Meter Conveyor

Conveyor Technologies XCC-.6M-1-SC-BR-AB 1/2 Meter Conveyor

Conveyor Technologies CC-.5-1-H-UL-HMI 1/2 Meter Conveyor

OK Industries Pick and Place SMT-8500 Double Head Pick and Place and Dispenser

Esico Triton Solder Pot 80T 1200W With Adjustable Thermostat

JAKEMY 123mm Anti-static Anti-magnetic Curved Forceps Tweezer Maintenance K2

17281 DESCO FOOT GROUNDER MEDIUM FULL COVERAGE QTY 1 NEW

2008 ACE KISS 102 Selective Solder Machine LEAD FREE

Batch Oven with Nitrogen !! Demo model !!

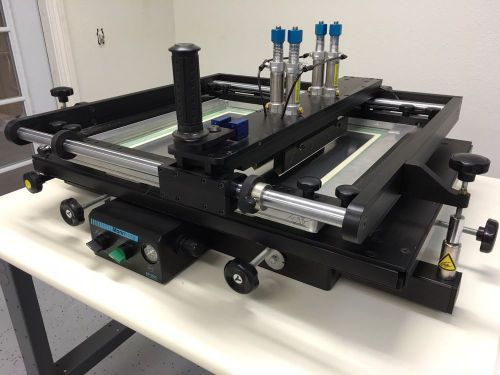

Semi Auto Printer with Auto drive Squeegee ! Vertical Lift !!

People who viewed this item also vieved

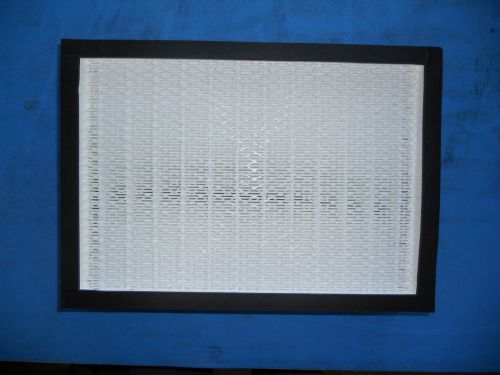

NEW AAF Astrocel II Cleanroom Air Filter 29E59B2Z3M3 16 3/4" x 11 3/4" x 3 3/4"

PURE Image Cleanroom Paper 8 1/2x11 250 Shts/Pk Yellow Lot No: 08311521

Berkshire Cleanroom Paper 8 1/2x14 250 Shts/Pk Item# BB104.0814.10W

ACME TRANSFORMER FUSE BRACKET, PL-112703

VP Vision Psytec VMX-3100M Wafer Surface Microscope Hayashi Luminar LA-180e

Industrial Products Group Inspection X-Y Motorized Stage Camera Flexible Arm

Dalsa CT-P1-4096W-ECEW CT P1 ECEW 4096W CCD Camera

Bruker AXS BD-4 XRF Controller w/ SNetZ XSPV & MCONT Modules

MEC Tech: Electrode, Manometer, Vespel, 200mm Part # MEC86008-1050 NEW

NOVELLUS SYSTEMS / GASONICS A90-031-03 PCB, Plasma/Lamp, Failure Detection

NOVELLUS SYSTEMS PCA, CVD-W INTERLOCK 03-10748-00 NEW

Applied Materials 0010-24774 ESC Assy 300MM SMALL OD

SMC 815017-440 Valve Solenoid MANIFOLD BASE, VVQ1000-10A-1, VQ1101Y-5, VQ1A01Y-

SVG THERMCO 815017-441 SMC US20096 Valve Solenoid MANIFOLD,PNEUMATIC,8 STATION,

AVIZA TECHNOLOGY 815017-444 SMC TIUB07W-20 TUBING,POLYURETHANE,.250 OD,WHITE, 1

VACO - Allen Wrench Hex (Tee) T-Handle,5/16 x 9"OAL NEW-Made in USA-Sold by each

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies