US $769.00

Directions

Similar products from Pad Printers & Accessories

Full Set Screen Pad Printer Printing Gravure Golf Pen Logo Print Curve Surface

Pad Printing Plate Coating DIY Inkcup Printer Die Tool Printing Transfer New

Pad Printing Press Printer Machine Pen Ball Clothe Label PVC Mug DIY Gift Logo

Automatic Pad Printer united silicon Up550

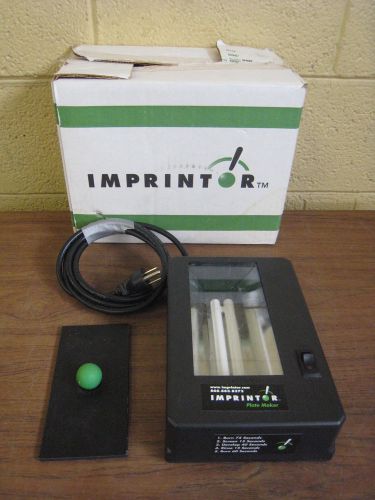

Imprintor C210 Imprinter Pad Printing Plate Maker Used Free Shipping

4 pcs Pad Printing Rubber Head Silicone Pad

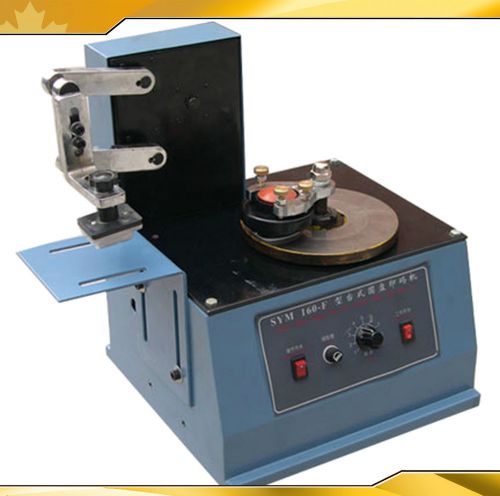

Manual Single Color Pad Printer with Sealed InkCup Pen Ball Label PVC Mug LOGO

New Pad Printing Machine Manual Pad Priter Pen Ball Label PVC Mug DIY Gift Logo

Full Set Pad Printing Kit for Ball Logo DIY Print Transfer

8 pcs Pad Printing Rubber Head 1.2" 2" 3.6" Soft Silicone Pad Brandnew

PRINTEX COS-100/4 4 COLOR PAD PRINTER

Pad Printing Machine with Oil Inkcup Exposure Unit Emulsion Coating Machine Kit

Pad Printing Automatic Emulsion Coating Machine Coater Steel Plate Maker 011003

New Desktop Electric Pad Printing Press Printer Machine Bottle Label 151050

New Desktop Electric Pad Printing Press Printer Machine Bottle Label DIY151050

SERVICE TECTONICS PAT-A-PRINT PAD PRINTER 805 INK CUP AIR OP 56223-0107

90mm Ink Cup with Ceramic Ring for Closed Cup Pad Printing Machine - New

Magnetic Sealed Oil Ink Cup Pad Printing Print Part 2.76" Cup Transfer Printing

New Pad Printing Silicone Rubber Head Round Square Silicone Pad 3"x2.6" Soft

4 pcs Silicone Pad Printing Rubber Head 2 3 3.5 Pad Print Transfer Printing Head

People who viewed this item also vieved

BIG LOT OF MARABU MARASTAR SR PAD & SCREEN PRINTING INK. 37 CANS, 25 COLORS NEW!

THERMOFAX MACHINE 3M TRANSPARENCY MAKER 45FGA TATTOOS EQUIPMENT FLASH STENCILS !

68 Letter Manual ID Credit VIP Member PVC Card Embosser /Embossing Machine 68C

Howard Machine / Kwikprint - ( 210 ) 12pt. Spacers - hot foil stampiong Machine

Howard Machine / Kwikprint - ( 170 ) 14pt. Spacers - hot foil stampiong Machine

1" x 2.5" Black Brass Perpetual Engraving Plates 10pcs (includes 20 screws)

REVO 540C GEMVISION CNC 3D MILLING JEWELRY MACHINE

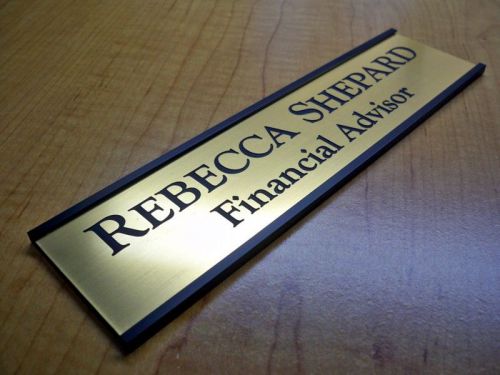

Custom Engraved 2x8 Door Sign Name Plate / Personalized Customized Brushed Gold

PLA 1,75mm dark green ca. RAL 6016 0,75kg - 3D Filament Supplies

PLA 1,75mm snow white 0,75kg - 3D Filament Supplies

Anajet mPower10i with all accessories

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies