US $749.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Ink Cups |

| Model | Sapphire J3 Series |

Directions

Similar products from Printing Ink & Electroink

Roland Eco Solvent compatible Ink, 1 liter bulk

Compatible Eco solvent bulk ink for mutoh valuejet and falcon outdoor

GEN Opaque Russell Purple Plastisol Screenprint Ink QUART

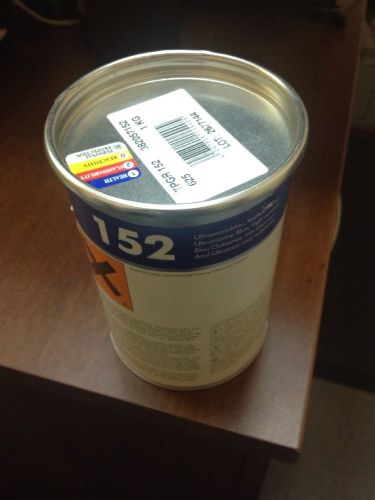

Marabu TPGR Pad Print Ink 152 Ultramarine Blue

Marabu TPGR Pad Print Ink 130 Vermilion

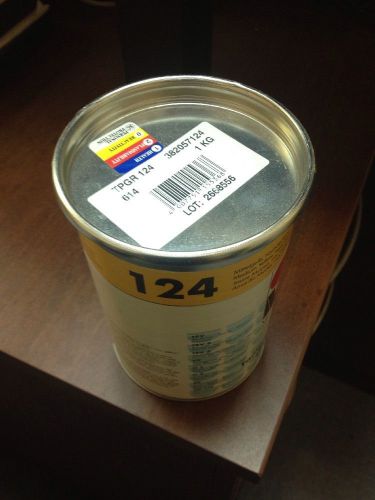

Marabu TPGR Pad Print Ink 124 Medium Yellow

Roland Auto Cutter Blade Olfa XB10 Original New Sealed

Triangle Ink Co, Eight Assorted 32 oz Size Plastisol Screen Printing INK's

Eco Solvent ink for Printhead Roland Mimaki Muton (6 Liters). AUS Seller

UC Multipurpose Warm Red UV Screenprint Ink Pint

UC Multipurpose Scarlet Red UV Screenprint Ink Pint

CSP Reflex Blue Corrougated Plastic Solvent Screenprint Ink Pint

CSP Primrose Yellow Corrougated Plastic Solvent Screenprint Ink Pint

CSP Emerald Green Corrougated Plastic Solvent Screenprint Ink PINT

CSP Process Blue Corrougated Plastic Solvent Screenprint Ink PINT

CSP PURPLE Corrougated Plastic Solvent Screenprint Ink PINT

CSP RHODAMINE RED Corrougated Plastic Solvent Screenprint Ink PINT

CSP RUBINE RED Corrougated Plastic Solvent Screenprint Ink PINT

GEN Opaque Brock Red Plastisol Screenprint Ink PINT

People who viewed this item also vieved

HYDROGRAPHIC WATER TRANSFER HYDRO DIPPING FILM HYDRO DIP SPRING TREE CAMO

HYDROGRAPHIC WATER TRANSFER HYDRO DIPPING FILM HYDRO DIP GRASSY CAMO CAMOUFLAGE

HYDROGRAPHIC WATER TRANSFER HYDRO DIPPING FILM HYDRO DIP ALIENS ALIEN

HYDROGRAPHIC WATER TRANSFER HYDRO DIPPING FILM HYDRO DIP ZOMBIE WALKING DEAD

DUCK HUNTING HYDROGRAPHIC WATER TRANSFER FILM COMBO 2 ROLLS OF FILM! FREE SHIP

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies