US $20.98

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Powder Coating Paint |

Directions

Similar products from Paints, Powders & Coatings

1 lb. Dark Roast Powder Coating

RUST-OLEUM Inverted Stripping Paint, White, 18 oz.

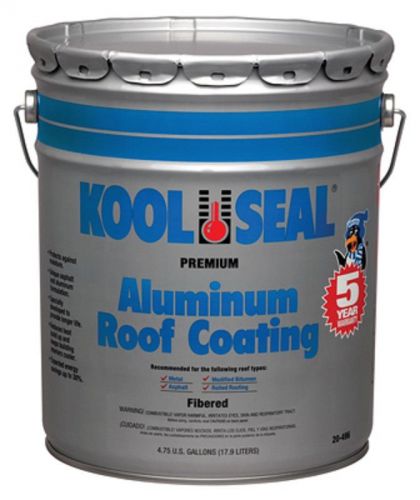

KST 4.75-Gallon Kool Seal Fibered Aluminum Roof Coating

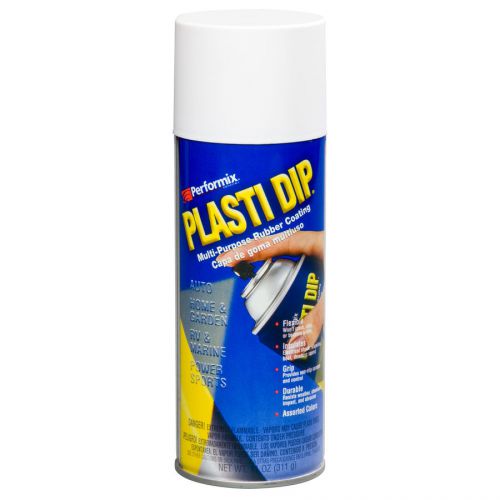

Performix PlastiDip WHITE 11OZ Spray CAN Rubber Handle Coating

Lot of 7 Aervoe 222 Fluorescent Survey Marking Paint Aerosol 20 oz (Orange)

3M 00051131074705 Scotch-Brite(TM) Roloc(TM)+ Clean and Strip XT Disc 07470,

3MIA9 048011183640 Scotch-Brite Roloc Coating Removal Disc TR, Silicon Carbide,

1lb. RAL 1001 Beige w/ Gloss Killer Powder Coating Powder Paint

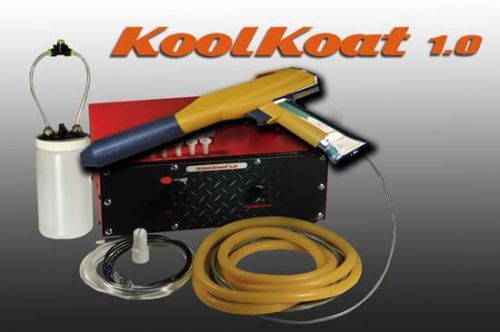

KOOL KOAT® 1.0 ELECTROSTATIC POWDER COATING GUN KK10LED ***FREE SHIPPING***

KOOL KOAT® 3.0 ELECTROSTATIC POWDER COATING GUN KK30LED ***FREE SHIPPING***

Powder Coating Paint Easter Island

Powder Coating Paint Christmas Island

Plasti Dip Ready to Spray 5 Gallon Pail Matte Black Rubber Dip Spray

1 oz. Prism Holographic Powder Coat Coating Additive

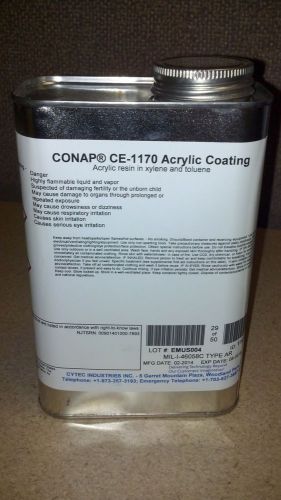

CYTEC - CONAP CE-1170 Acrylic Coating - 1.8 LB

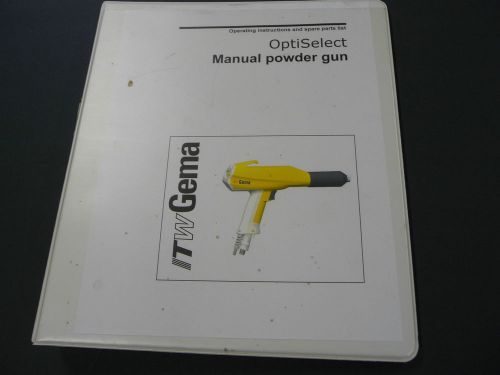

GEMA POWDER COATING OPTISELECT " GUN MANUAL " 47 PAGES GREAT INFORMATION

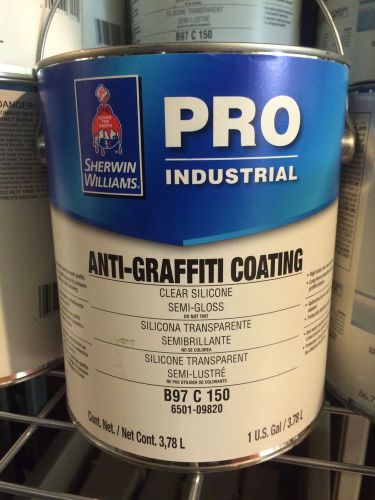

Sherwin Williams Anti Graffiti Coating

Deft Polyurethane Topcoat Paint Kit 03-GY-292 (Gray 36375) 1 Qt

Performix Plasti Dip Spray Cans 6 Pack Matte Black Rubber Dip Coating 11oz Cans

Plasti Dip Spray Cans 11oz 6 Pack Gunmetal Gray Plasti Dip Rubber Coating Paint

People who viewed this item also vieved

Klein Tools 32561 Stubby Multi-Bit Screwdriver-MLTIBT STUBY SCREWDRIVER

Zenith Prod. 36601SS04 Double Shower Rod

Crc Industries Inc. 19Oz Brake Cleaner 05089 -2Pk

Bestt Liebco 18" Rough Surface Paint Roller Cover 3/4 Nap All Paints Lot of 4

3M 06005 Premium Liquid Wax 1 Quart

FREE SHIPPING! Graco 221411 RAC 5 SwitchTip Reversible Spray Tip

Asphalt Sealcoat Sealcoating Ceramic Spray Tips 1/4" 80/70 and 80/50

Everhard Steel Roller Set Ball Bearing Seam Screen Spline Radius End Hand Tools

3M Resinite Floor Surfacing Discs Part #5144, Type TF, 15"X2" Box of 20

DEVILBISS 1 SV - 531 PROFESSIONAL SPRAY GUN ----- GOOD VALUE L@@K

Graco 207-385 Repair Kit For All President Air Motors

GENUINE GRACO, 239-639 GUN REPAIR KIT New

GENUINE GRACO DRAIN VALVE REPLACEMENT KIT 245103, New in Bag - Free Shipping

Graco Repair Kit 204-164 For 50:1 Fire-Ball Pumps Fluid Section-Opened

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies