US $2800

Directions

Similar products from Other Medical Devices & Machines

905 Diamond Microdermabrasion Photonrejuvenation UltrasonicScrubber Dermabrasion

7in1 Cavitation Weight Loss Slim Multipolar Tripolar Bipolar RF Vacuum Photon RF

Hot Sale Suitecase 2in1 Cellulite Dissolve Ultrasonic Cavitation Liposuction RF

Free Shipping Ultrasonic Cavitation Slimming Beauty Anti-ageing Wrinkle Machine

Mini RF Radio Frequency Skin Tighten Lift Machine Bipolar RF Skin Rejuventation

Mini Microdermabrasion Hydro Dermabrasion Hydro Peeling Facial Wrinkle Remove ce

Microdermabrasion Dermabrasion 3in1 Spray Peeling Firm Skin Lift Rejuvenation

40K Cavitation Ultrasound 1Mhz Ultrasonic Body Shape Weight Loss Machine Beauty

WELCH ALLYN Transformer Diagnostic Duo Handles 74710 for Otoscope Opthalmascope

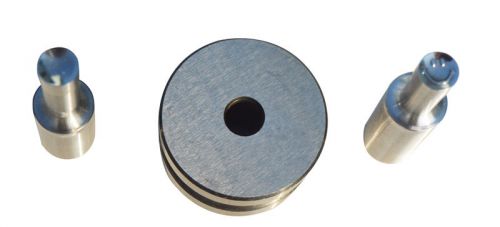

Promotion Professional TDP-1.5 Pill Maker Die Smile Pill Maker Press Machine

ipl hair removal laser skin rejuvenation pigment freckle vascular ance removal q

Moberg Medical Neurotrac II Electro EEG Computer Module

IPL Laser Hair Removal Skin Rejuvenation Elight Wrinkle RF Radio Frequency E-200

7-1 Diode Lipo Laser 40K Cavitation Ultrasound Vacuum Sextupole Tripolar RF Slim

Synthes 357.399 3.2mm guide wire

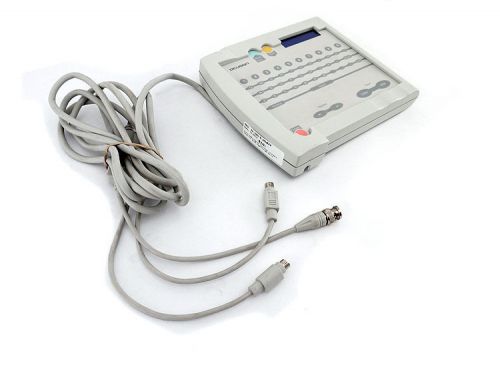

Acuson Aegis Digital Controller Interface Keypad for QV100 Image Storage Device

4in1 Soft Variable-frequency RF Bipolar Skin Lift Ultrasonic Cavitation Slim Spa

Fractional Vertical CO2 Laser Surgical System Engraving Marker Acne scars Cut

New 6L Liquid Nitrogen LN2 Tank for storage animal tissues, Cryogenic container

650nm Diode Lipo Laser Body Slimming LLLT Cellulite Removal Weight Loss Machine

People who viewed this item also vieved

Omni-Tract 3424 Stainless-Steel Surgical Sterilization Tray Case Pan Cover

SIEMENS RapidLab 1265 Blood Gas Analyzer 1200 Series Automatic QC

Posey Sitter 8225 Duality Control Unit (Fall Alert System/ Alarm Unit ) (10553)

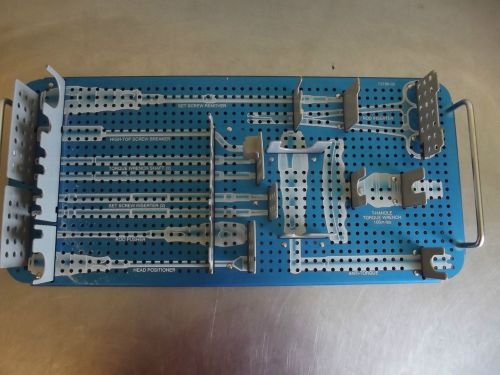

Orthopedic Surgical Instrument Case Insert #73799-02-Good Shape-m1307

Lot Of (1) Disposable Surgical Drape 38" +/-2" W X 100 Yards Light Blue

Case Of Covidien Kangaroo E Pump Spike Sets

lot of catheter syringe bd 2oz 60 (ml)

Fisher & Paykel Eson small cushion lot of 5

Fisher & Paykel Simplus small cushion lot of 5

Fisher & Paykel Eson medium cushion lot of 5

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies