US $130

Directions

Similar products from Gauges

TS40-300PSI Air Pressure Gauge Meter Piezometer Double Scale 0-300psi TA L7Y9

TS50-100PSI Air manometer pressure Gauge Piezometer Test Single Scale TA Q1C9

Digital Tire Air Pressure Gauge Safety Hammer Seatbelt Cutter Flashlight Q7G1

UNI-T Handheld Digital Tire Pressure Gauge with Safety Hammer & Flashlight G8W1

UNI-T UT376 Car Auto Vehicle Tire Tyre Air Pressure Gauge Tester Tools TA D4Z9

USA Made 200 PSI Gauge NOS 2.5" Regulator Brass NOS

Ashcroft Gauge 1/8" BM 1-1/2" Face 0-30 PSI (1000-15)

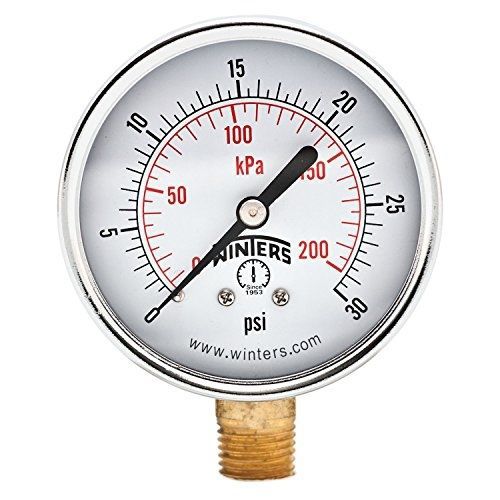

Winters PFQ Series Stainless Steel 304 Dual Scale Liquid Filled Pressure Gauge

MOELLER DIAL INDICATING PRESSURE GAUGE 30 PSIG ... VV-226

Pressure Gauge 1/4" NPT Bottom Connection 0-30 PSI Liquid Fill PGB254CLMC

Helicoid S.S. 4 1/2" Gauge 0-15 PSI with 1/2" Male NPT P/N J4J2C5A00000 NEW

Masterblend's El Diablo Water Temperature Gauge, #730013

Winters PEM Series Steel Dual Scale Economical All Purpose Pressure Gauge with

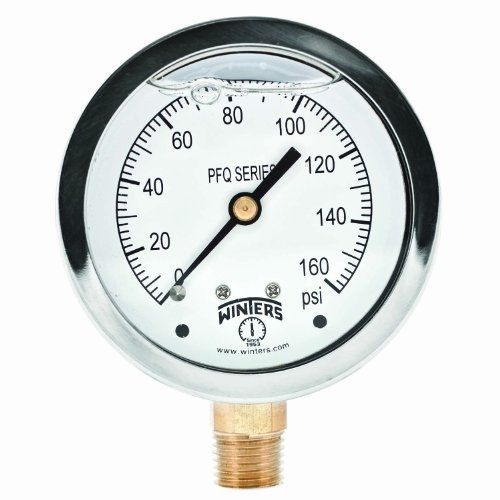

Winters PFQ Series Stainless Steel 304 Single Scale Liquid Filled Pressure Gauge

Perma-Cal 3-1/2" Panel Mount Process Gauge 0-30 PSI with 1/4" S.S. Male NPT Con.

SMC AR2060-02 0-1 MPa Pressure Gauge (Lot Of 2)

SMC AR2560-03 Air Regulator 0.2-1MPa Pressure Gauge (Lot Of 2)

Winters PFP Series Premium Stainless Steel 304 Single Scale Liquid Filled Pressu

PneumaticPlus Air Pressure Gauge 1-1/2" Dial, Lower Mount, 0 - 160 PSI, 1/8" NPT

People who viewed this item also vieved

Deltech D-0600-cf compressed gas filter system

NEW WACO 21148136 AIR PNEUMATIC FILTER ELEMENT D313370

(N1-1) 2 HENRY 848-F FILTER ELEMENTS

Hudson Oxygen Regulator w/ Gauge No 2080

Frl,1/2 In. Npt, 120 Cfm, 32150 Psi ARO

POSI-DRAIN PD7020 DRAIN VALVE TIMER 120 VAC, 60 HZ, 30W 200 PSI max

LOT OF 3 INGERSOLL-RAND PISTON RING PART NO. 50A18BA806 - COMPRESSOR PART

Hankison Refrigerated Dryer Maintenance Kit # RDMK1

1/4" X 25' POLYURETHANE COIL AIR HOSE up to 100PSI NEW

Husky 20 gallon Air compressor Model H1820F Gauge Cover w / Rubber & Screws

air compressor pressure switch 70-100 psi,brand new,never used.

UE UNITED ELECTRIC H121-S156B PRESSURE 100PSI SWITCH 125/250/480V-AC 15A B213634

Vindum Engineering CV-410 10kPSI High Pressure Constant Volume 2Way On/Off Valve

Ingersoll Rand 37966702 high pressure switch

Ingersoll Rand ARO A213SD-024-D-G solenoid air Valve 4 way 2 position

MOORE 41-30 PRESSURE AIR 0-30PSI 1/8 IN NPT PNEUMATIC REGULATOR B267998

MOORE 41-30 NULLMATIC PRESSURE NPT 0-30PSI 1/8 IN PNEUMATIC REGULATOR D363017

B&K Ball Valve NEW (10) 1/2" 150wsp-600Wog- 400Psi--107-703

NORGREN B07-202M1EA INLET 150PSI 1/4 IN NPT PNEUMATIC FILTER-REGULATOR B313393

FISHER SCIENTIFIC DUAL GAUGE PRESSURE REGULATOR 0-60PSI 0-2000PSI

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies