US $4,475.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Romaxx |

| Country of Manufacture | United States | ||

| Model | WD-1 | ||

| Romaxx | CNC |

Directions

Similar products from Professional Router Machines

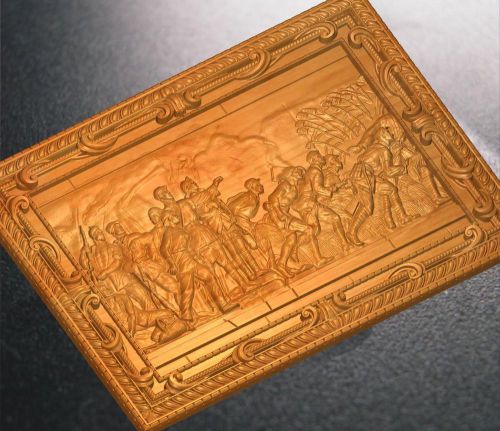

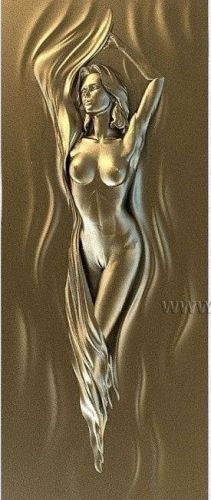

3D model of STL excellent kachestva.cnc

1313 CNC 3d Relief Model STL for Router Engraver Mill Woodworking 3D printer

6 Pcs. Techniks BT 30 ER 16x 60mm 25K RPM @ G2.5 Balanced CNC Collet Chucks

CNC 3D Router Models in STL Format / Trim and Panel / CNC Machines / Engrave NR!

4 axis USB CNC breakout board interface board USBCNC with Handle control RATTM

3040C 4 Axis CNC Router Engraver Handicraft Anaglyph Badges Engraving Machine

3 d model stl artcam cnc router

Merry Christmas Graphic, G-code Mach 3 and Generic versions

Delta Rockwell Homecraft router wood shaper Main casting/ rear legs

Delta Rockwell Homecraft Wood Shaper Table top Casting SR101

3 Axis CNC 3040T-DJ Router Engraver Engraving Machine + Clamp Tools

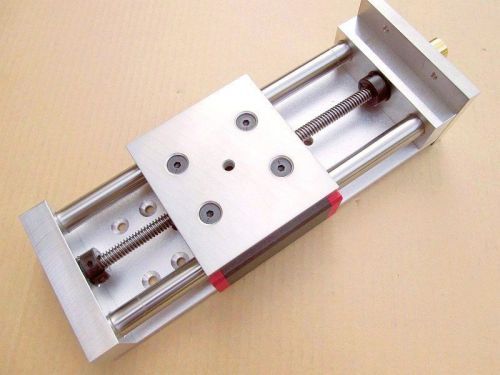

NSK C3 ground ballscrew 12-5mm L215mm Travel 115mm BALL SCREW

ROUTER CNC ENGRAVER DESKTOP 3020T DRILLING/MILLING MACHINE ENGRAVING

CNC Supported Shaft 20mm 55" an 2 Bearing Special $99

Vintage Craftsman planer shaper cutters lot Antique wood shop tool hardware

3D Pantograph Engraving machine

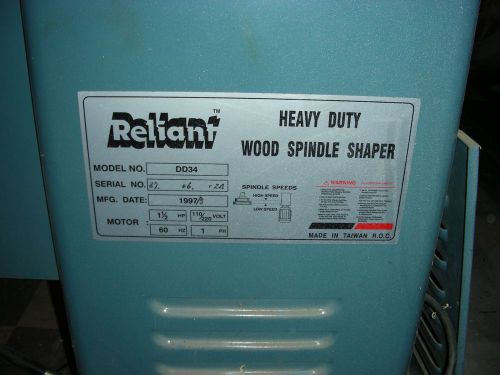

Reliant DD34 Heavy Duty Spindle Shaper Used

PORTER SINGLE HEAD INVERTED ROUTER MDL#: 622SH

Capitel 11 CNC 3d Relief Model STL for Router Mill ArtCam Aspire Cut3D 3D printe

Z Axis Linear Slide CNC Router X Y Plasma Optics 3D Printer 5" Fast-Travel

People who viewed this item also vieved

Gang Rip Saw - Steton 12" Dip Chain Gang Rip Saw - model #SM 300

NORTH AMERICAN VERTICAL BANDSAW (11269)

Jeweler Saw Frame 3" Adjustable French Style with 12 Blades Jewelry Hobby #71SF

DELTA ROCKWELL Drill press Upper bearing Drive Collar #DP-250

Clausing Drill Press Model 2274 - PARTS AVAILABLE

Walker Turner Press Spindle Cap Cover Guard

Mirka Abralon 8A-203-2000 3" Foam Sponge Back Grip Wet/Dry Discs/20bx

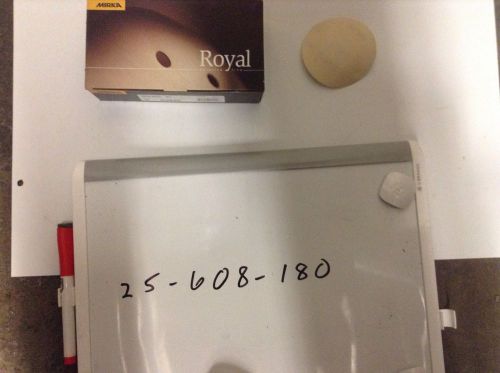

Mirka 25-608-180 3" Grip (H&L) 180gr Sanding Disc (50pk)

AEG made for Birkenstock COMMERCIAL 2" BELT SANDER GRINDER w/ chuck attachment

DELTA ONSRUD 43-276 INVERTED PIN ROUTER (MULTI SPEED)

Mini Lathe Beads Machine Woodworking DIY Lathe Standard Set with Power DC 24V

Wood Lathe Delta Rockwell 11 in wood lathe 46 140

Jet Gap Bed Lathe GH1340-A Enco Sharp Victor Summit Grizzly Acer 13x40 14x40

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies