US $13000

Directions

Similar products from Inspection Tools & Machinery

HP AGILENT KEYSIGHT POD CABLES #3-4 Mesh

HP AGILENT KEYSIGHT POD CABLES #1 - 2 Mesh

HP AGILENT KEYSIGHT POD CABLES #5 - 6 Mesh

HP AGILENT KEYSIGHT POD CABLES #7-8 Mesh

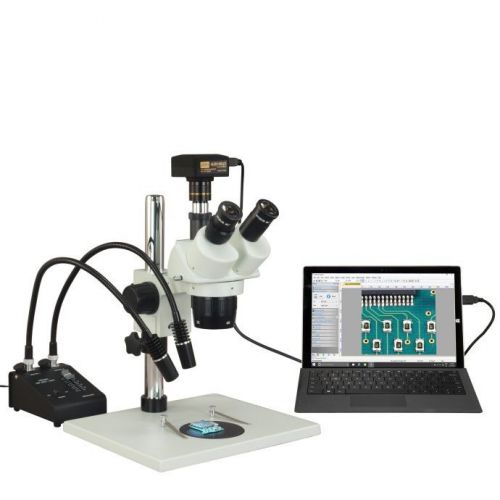

Trinocular 10X-20X-40X-80X 18MP USB3 Stereo Table Microscope+6W Gooseneck Light

Trinocular 10X-20X-40X-80X 14MP USB3 Stereo Table Microscope+6W Gooseneck Light

Trinocular 10X-20X-40X-80X 10MP USB3 Stereo Table Microscope+6W Gooseneck Light

Trinocular 10X-20X-40X-80X 5MP USB3 Stereo Table Microscope+6W Gooseneck Light

Tektronix P6022 Current Probe w/011-0106-00 Termination. 935Hz to 120MHz. 5 ft.

Leica Leitz Ergoplan 8 Inch Inspection Microscope & Leica INS 10 Wafer Loader

Veeco Model: AP-150 FPP Automatic Resistivity Probe <

Optem Int'l / Magnetic HF-65 Scope Station w/ Remote<

Nikon Optistation A Wafer Inspection System

PLASMOS SD-2000-LC Automatic Ellipsometer (Metrology)

Rudolph FE-III (FEIII) Focus Ellipsometer (Metrology)

Litton Ind Automation 89TS05250 Connecting Cable

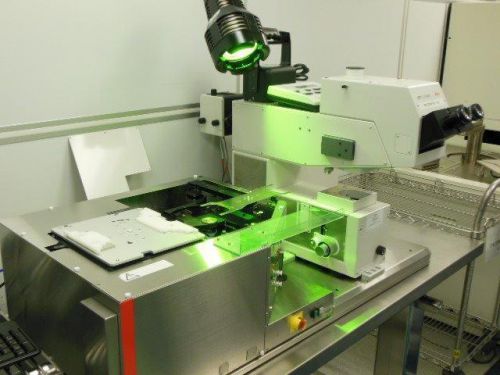

Inferometry optical surface profiler parts machine

Olympus BX-DUV-LHAD Arc Lamp Interface Module

Olympus BX-DUV-RLAA Microscope Assembly w/ U-D5BDREMC

People who viewed this item also vieved

Camfil Farr PX-23.62-59.62-9-Z3-00-1D-00-0 LF Panel Air Filter 855024933

SIMCO IN LINE IONIZER WITH S165S POWER SUPPLY BRAND NEW IN THE BOX

Deviser DW-420S Cleanroom Blower Exhaust Fan 47" x 23" x 12"

DNS Wafer Support, TR UN IT Arms, 2F482408, New

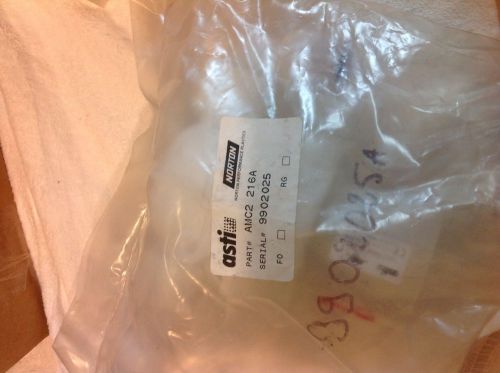

NEW AstiPure Saint-Gobain AMC2 216A 216 PFD2 AMC Pulsation Pulse Damper 216K

Station Sensor Solenoid Assembly BM200630000 Rev K, New

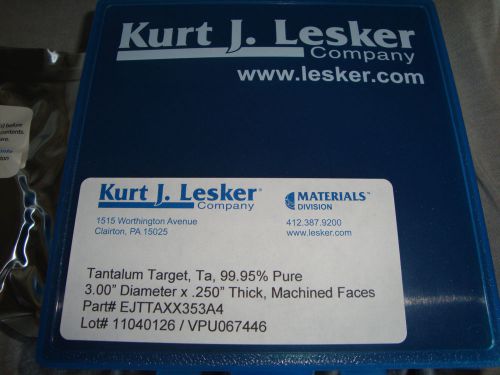

New Tantalum sputtering target 3" 99.95% pure

Straight Anti-static Tweezer Maintenance Tool ESD-11

Straight Anti-static Tweezer Maintenance Tool ESD-12

Straight Anti-static Tweezer Maintenance Tool ESD-14

Straight Anti-static Tweezer Maintenance Tool ESD-13

Comdel CLF-500/400 RF Power Supply, Part # 1140-01110

Hiden Analytical HA-053-607C Valve Controller

PAR Systems Gantry Laser Robot for large area CNC milling: 6x20'

B & B Electronics 485OTLED Optically Isolated RS-422/485 Converter

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies