US $2,299.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | CapsulCN |

| Voltage | 110v / 220v | ||

| Country/Region of Manufacture | United States |

Directions

Similar products from Punches & Dies

Lustre Line 8500 Vtg Power Puncher Metal Hole Punching Tool Kit Set

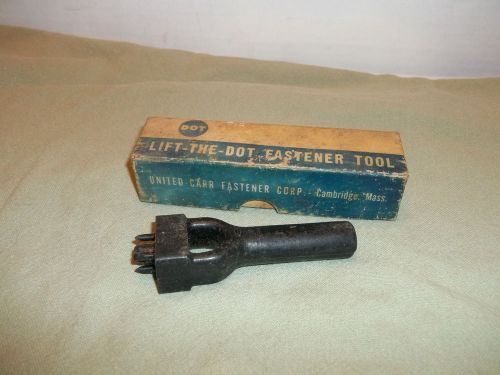

VINTAGE LIFT THE DOT FASTENER TOOL #147

Greenlee 2 1/2" #738 63.5mm Knockout Punch Whole Punch Knock Out

Greenlee 1/2" Knockout Punch Whole Punch Knock Out

Greenlee 3/4" Knockout Punch Whole Punch Knock Out

Greenlee Knockout Punch Draw Stud 3/8" x 2 7/8" Overall Length 2" Draw 5003997

Greenlee 1 1/8" Knockout Punch Whole Punch Knock Out

Enerpac 3/4" Knockout Punch Whole Punch Knock Out

GB Enerpac 2 in. Knock Out # 2000

GREENLEE 2 Conduit Die KNOCK OUT PUNCH AC441-1 SET

ENERPAC 2 KD2000 2 Die KNOCK OUT PUNCH SET

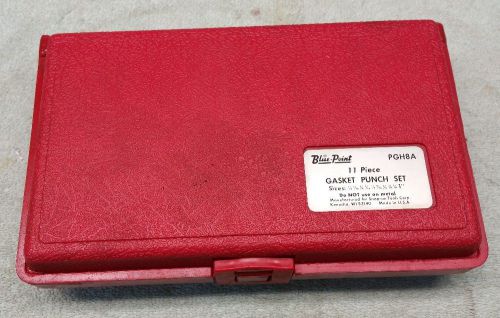

BLUE-POINT 11-PIECE GASKET PUNCH SET 1/4" TO 1" PGH8A

NEW RIDGID 47995 3/8IN-16 UNC (RH) ALLOY STEEL UNIVERSAL BOLT DIE SET D359705

Greenlee 731 Radio Chassis Knockout Punch 7/8" Square

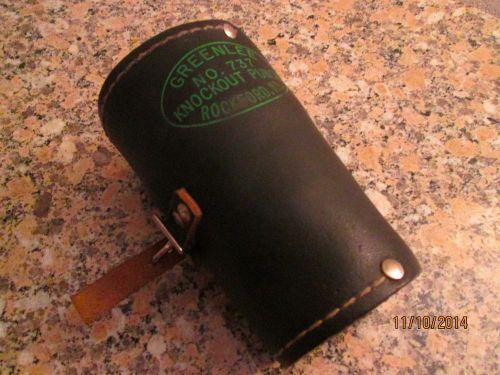

VERY NICE Greenlee No. 737 Knockout Punch & Dies Tool Set Leather Case ONLY

NEW RIDGID 47995 3/8IN-16 UNC (RH) ALLOY STEEL UNIVERSAL BOLT DIE SET D359713

Vintage Greenlee Metal Stud Punch Model 710 Capacity 2.5", Diameter 1-11/32"

Greenlee Hydraulic Hole Punch Set

GREENLEE 229 9-PIN D-SUBMINIATURE PANEL PUNCH EXCELLENT CONDITION

Craftsman 1/4" Center Punch 428186 Tool

People who viewed this item also vieved

GREENLEE Retrofit Knockout Punch&Die Set, Self-Centering, 1/2"-2", 10ga Steel

Greenlee 7906SB Quick Draw 90 Hydraulic Punch Driver Kit

Greenlee 767A Hydraulic Hand Knockout Punch Pump & Ram w/Dies Set

GREENLEE 7904-E Quick Draw 90 Hydraulic Punch Driver Kit AS PICTURED

Greenlee 767 Hydraulic Hand Pump w/ 746 Ram Good Deal!!

Greenlee Hydraulic Knockout Set

Greenlee 7806SB Quick Draw Hydraulic Punch Driver Kit *Please Read*

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies