US $6.98

| Condition | New other (see details)

:

A new, unused item with absolutely no signs of wear. The item may be missing the original packaging, or in the original packaging but not sealed. The item may be a factory second or a new, unused item with defects. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “New reproduction.” |

Directions

Similar products from Instruction Manuals for Metal Cutting

Keep Your Lathe In Trim Manual 6767-807

Turret Lathe Operators Manual-Warner & Swasey 1940- Hard Cover

1946-47 RYERSON STEELS CATALOG JOSEPH T RYERSON & SON INC CLEVELAND OHIO

NORCO ALLOYS CORP ALLOY REFERENCE GUIDE STEEL NICKLE TITANIUM

Thompson Parts & Service Manual for 2F Surface Grinder (Inv.18036)

Thermal Dynamics PAK 3 Plasma Cutter Instruction Manual *970

Thermal Dynamics CutMaster 81 Plasma Cutter Operating Manual *950

Logan 10" Lathe Models 200, 201, 210, 211 Instructions & Parts List Manual *1063

Thermal Dynamics Pakmaster 100 XL Plus Plasma Cutter Operating Manual *1017

Thermal Dynamics PakMaster 100XL Plus Plasma Cutter Service Manual *1018

Tools for Sheet Metal Work: Niagara Machine and Tool Co Catalog (Lindsay book)

W.F. & John Barnes Co. Metal Working Machinery catalog - 1897 - ORIGINAL

REMS Turbo Cu-INOX Pipe Sawing Machine

1925 International Model “S” Truck Instruction Book - reprint

TECHNICAL MANUAL FOR CINCINNATI MILACRON BRUSHLESS DC-PWM DRIVE CONTROLLER

CINCINNATI MILACRON CINTURN 2 AXIS TURNING CENTERS 1208 1210 1212 SERVICE MANUAL

CONTROL REFERENCE MANUAL FOR CINCINNATI MILACRON ACRAMATIC 850SX MC/TC CONTROL

INSTRUCTION MANUAL FOR SIEMENS SIMODRIVE 610 TRANSISTOR PWM INVERTER

OPERATING MANUAL FOR CINCINNATI MILACRON CINTURN TURNING CENTERS 1208 1210 1212

CINCINNATI MILACRON CINTURN 8C ALERT CODES REFERENCE GUIDE

People who viewed this item also vieved

18" Sheet metal Fabrication Kit

1950 1st Ed-1st Print DESIGNING FOR ALCOA FORGINGS Hardcover VERY GOOD CONDITION

Machinery"s Handbook 24th Edition -Hardcover.by Industrial Press Mint Condition.

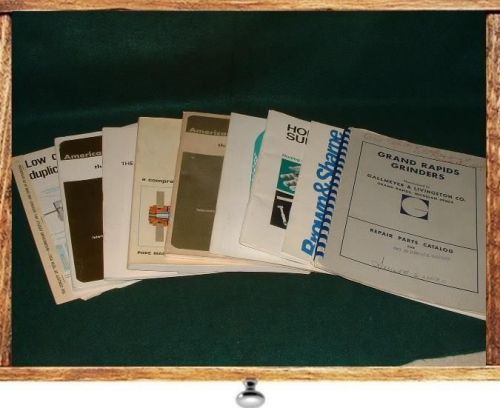

LOT OF 10 MACHINIST GRINDER GRINDING CATALOGS #009

Strength of Materials Third Edition Part II Advanced Theory and Problems

Gould & Eberhardt shaper manual and parts

OPERATING INSTRUCTIONS: JONES & LAMSON AUTOMATIC THREAD GRINDING MACHINE #RR226

1st edition Soldering & Brazing Manual by James T. Hobart,M.E.

HURCO cnc Programming Manual Ultimax 3

How To Make Knurler For Lathe Nutcracker Knurler Knurls Metal Parts Turning #322

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies