US $2,200.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Thermco |

| Model | 8610 | ||

| Country/Region of Manufacture | United States |

Directions

Similar products from Other Gas & Fluid Monitoring Tools

3 ea 36" or 3' Matheson Tri Gas CGA 580 SS Reinforced Flex Hose for Manifold NOS

4 ea 36" or 3' Matheson Tri Gas CGA 580 SS Reinforced Flex Hose for Manifold NOS

3 each Matheson Bracket Mounting Kit MSRS-1455-BO & MSRS-1470-BO NOS

Matheson Single Cylinder Wall Bracket MSRS-1464-B0 Pt# M710 Model M711-C NOS

Matheson Single Cylinder Wall Bracket MSRS-1464-B0 Pt# M710 Model M711-C NOS NIB

40" Amico Pigtail Stainless CGA-326 Nitrous Oxide Hose M-X-HB-PTS-N20 NOS

4 ea 3' Matheson Tri Gas CGA 360 SS Reinforced Flex Hose 400V ck valve Manifold

51808 LOC-LINE Y Fitting Pk 2 Loc Line 1/2"

1-1/2 inch Tri Clover 304 Stainless steel Sanitary Clamp with End cap

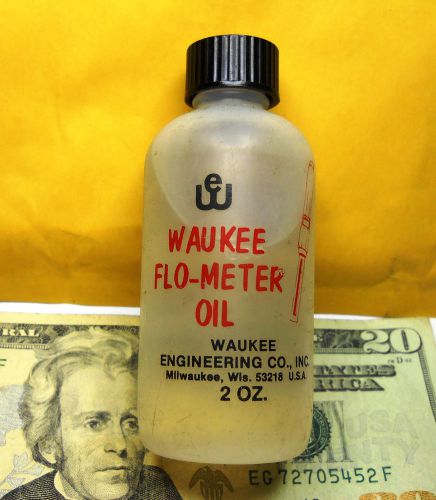

WAUKEE 2oz BOTTLE FLO-METER FLOWMETER FLOW METER OIL 6 pcs.

Thermco Gas Mixer Model 8505 NEW

HOFFMAN 41 AIR VALVE CONVECTOR 1/8" 401455

GILBARCO T16394-G1 POWER SUPPLY BOARD

AEROQUIP 5400-S2-8 REFRIGERANT COUPLING

SWAGELOK SS-810-1-8 MALE CONNECTOR 1/2" TUBE x 1/2" MALE NPT

Drum Heater Adjustable Thermostat 1500W Industrial Silicone drumH12

1 INDUSTRIAL SCIENTIFIC M40 Multi- Gas Monitor. Comes with a case.

Industrial Scientific SP40 Sample for M40 Multi-Gas Monitor PUMP ONLY

NEW KOBOLD 1" NPT STAINLESS STEEL FLOW SWITCH TYPE PSR-25

People who viewed this item also vieved

Victor Compressed Gas Dual Gauge Regulator Air 60PSI 4000PSI Draft Beer CO2

Harris Compressed Gas Dual Gauge CO2 Regulator Air 200PSI 4000PSI Draft Beer

ProStar Compressed Gas Dual Gauge Regulator Air Gauge CGA320 15LPM 4000PSI

Matheson Compressed Gas Dual Gauge Regulator Air 60PSI 3000PSI

Fisher Brand Compressed Gas Dual Gauge Regulator Air Gauge CGA580 200PSI 4000PSI

Sanitary pipe fitting tee 1" tri clover 3/4 " NPT female , 5" x 4"

sanitary pipe fitting, extension, 1-1/2"x 4", stainless, tri clover ends

sanitary pipe fitting, extension, 3/4"x 4", stainless, tri clover ends

Sanitary pipe fitting tee 1" and 1 1/2 " tri clover type , 5" x 5"

sanitary pipe fitting, ell elbow 3/4" tri clover type 3-1/2" x 3-1/2"

HILL-ROM 1" Medical Ball Valve W/ Port

Autoclave Engineers 30VM4072 HT High Pressure Temp Needle valve 30,000 PSI 316SS

Vintage Brass Crane Co. 2550 Relief Pop Off Steam Valve 80psi 1/2"

2 Pcs.King Instrument Company 75301112C15 2" /BR/EPR/BR/180SCFH

Dwyer RMA-7-SSV Rate-Master SCFH Air Flowmeter Units

NEW BROOKS INSTRUMENT Flowmeter 1305EL1ACJ2BA

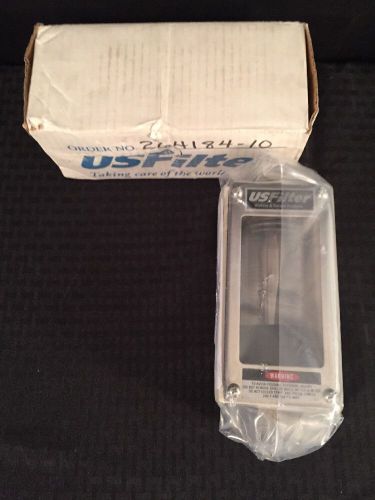

NEW US FILTER Series 55-100 Direct View Flowmeter 264184-10

Barco Venturi Flow Measurement Sysytem

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies