US $11431

Directions

Similar products from Combined Cipher Machines & Comparators

JONES & LAMSON OPTICAL COMPARATOR & MEASURING MACHINE - MODEL PC-14

MITUTOYO PV-350 VERTICAL OPTICAL COMPARATOR B33858

MITUTOYO TOUCH SIGNAL PROBE - 902329

SHINKO S.G PROMINAR # 500013 50X LENS #500013 $229

Zeiss RT05-800 CNC CMM w/ Air Bearing Table, KMZ-S 121210, Good Condition

Used Renishaw TP200 CMM Probe Body and 3 used TP200 SF Modules with Warranty

Ultramatic Vibratory Tumbling Finishing Machine Debur Vibe 4 cubic Foot 110V

ARREY JONES ONLY 8GBIT FC FRON MC00019688 EXPIRES 12/14/2017 (78004686) (Lenovo)

SUBURBAN No. MV-14 OPTICAL COMPARATOR 14"

Revware MICROSCRIBE MX 3D Digitizer / Portable Measurement System (2013)

Used Zeiss C-700 CMM Coordinate Measuring Machine Renishaw TP-20 MH8 Calyspso 88

Mini Optic Comparator 8" x 8" x 15" Bausch & Lomb

Mitutoyo Bhn-706 Shipping kit (RENTAL ONLY)

Renishaw EC10 GOLD STANDARD Laser Interferometer

Renishaw EC10 Laser Interferometer

Renishaw ML10 Laser Interferometer

Scherr Tumico Optical Comparator (P-2600)

SHEFFIELD CORDAX 1808 CMM MEA Coordinate Measuring Machine W/ Renishaw MIH Probe

People who viewed this item also vieved

2 MITUTOYO ID GROOVE BORE MICROMETERS AND HELIOS MEASURING CALIPER VERNIER 160MM

L.S. Starrett No. 123 E & M Vernier Caliper 14.5" (No Box)

Handy Tech Model SH4150 RPM Indicator (BA3)

~Vintage~ STARRETT No.64A Test Indicator

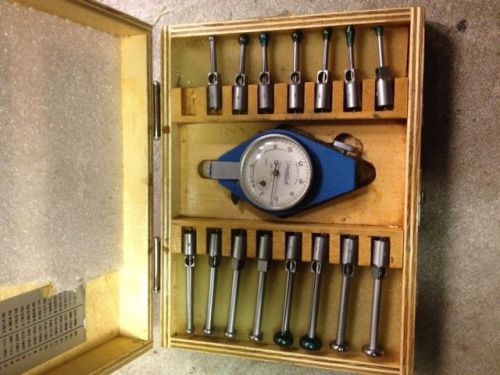

Fowler Dial Bore Gage .0005 Tool

Jo-Plugs #0-80 Precision CMM Tapped Hole Location Gage/Gauge Set Solid Spencer

Starrett No. 724 Outside Micrometer 30" 36"

Starrett No.449 Blade Depth Micrometer Set In The Case

Vintage Starrett 98-12 machinist level

Starrett 257 Surface Gage with 3.500 X 3.125 Hardened Base, 12.000 & 18.000 spin

STARRETT TOUGH TIP REPLACEMENT BLADE

LS Starrett No. 289A Key Seat Rule Right Angle Square Clamps Attachments 289-A

Starrett 6" No.13 double square Good Condition

VINTAGE CRAFTSMAN SLIDING T BEVEL SQUARE MADE IN USA

MIGHTY MAG INDICATOR HOLDER, 400-1 MADE IN USA, B12

Mitutoyo Magnetic Dial Indicator Stand Base 7010SN

SPI DIGITAL 360 PROTRACTOR LEVEL W/CASE & INSTRUCTIONS

NEW Starrett C19 Steel Protractor

NICE SET SHARS 36 piece grade 2 Gage Block Set # 236044 NIST Test #821/263310-00

Pratt & Whitney gage block .700 S797A

used fixture jig 30 x 60 degree block mills drills surface grinder lay-out

COLLINS MICROFLAT GRANITE SURFACE INSPECTION PLATE 12"x18"x4" S/N:75273

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies