US $40.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | TRANSBRITE |

| Country/Region of Manufacture | United States | ||

| Model | 7000 |

Directions

Similar products from Power Washers & Spare Parts

Landa ECOS mobile wash reclaim system

Graco G-Gorce 4043 Belt Drive Pressure Washer 4000 Psi 16hp G05B Series

Karcher Hds 1055 Hot Water Pressure Washer

NEW CATERPILLAR CAT 7C-9770 GASKET ENGINE/MACHINE TRUCK REPLACEMENT PART B491622

Dry Ice blasting equipment w/ accessories

Cat Pumps Pressure Washer Pump, 2750 PSI, 2.5 GPM, Model 3DNX25GSI

Cat Pumps Pressure Washer Pump — 2 GPM, 1500 PSI, 2 HP Required, Model# 2SFX20

CAT Pumps Pressure Washer Pump — 3.5 GPM, 4000 PSI, Model# 66DX35G1I

Landa hot pressure washer, gas ,Diesel, portable MHP4-3000 ONLY 67 hours

PRESSURE WASHER Electric - Commercial - 1.5 Hp - 110V - 1,100 PSI - 2 GPM - CAT

PRESSURE WASHER Electric - Commercial - 2 Hp - 110V - 1,500 PSI - 2 GPM - CAT

Whisper Pro White Brush Assembly WW-302 (1/2" Taller)

Whisper Pro 24" Spray Bar Assembly with 2 Nozzles GF504-2

Whisper Pro 19" Spray Bar Assembly with 4 Nozzles WW-300-4

Whisper Wash 16" Spray Bar Assembly with Nozzles UC-616HC

Whisper Wash Whisper Pro Rotor Shaft Replacement WW-136

Whisper Wash Whisper Pro Bearing WW-138

WW-200 Whisper Wash Seal Kit (Old Style) for WW-128 Swivel

WW-311 Whisper Wash Rebuild Cartridge Series 3 Fits Whisper Pro Models

People who viewed this item also vieved

BETCO ONE STEP- 61804 Cleaner, Restorer 1 Gallon

Favored Practical Magic High Tech Cleaning Compound Super Clean Slimy Gel GP

1 set Mini Wire Brush Plastic Handle Brass Nylon Stainless Steel Bristle New

Original Smokers Cease-Fire Cigarette Butt Receptacle justrite

Rubbermaid Commercial Wavebrake Dual-Water Down-Press Bucket/Wringer Combo, 8.75

Rubbermaid Commercial Wavebrake Bucket, 8.75Gal, Yellow

Kimberly Clark IN-SIGHT Lev-R-Matic 09767 Roll Towel Dispenser Smoke NEW IN BOX

GP Enmotion 59462 Classic Automated Touchless Paper Towel Dispenser Smoke NEW!

Georgia-Pacific Compact 4 Roll Toliet Paper Dispenser

Bobrick 273-103 Replacement Spindle for Toilet Tissue Dispenser

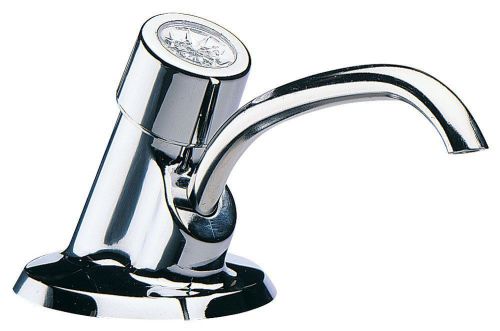

Kimberly Clark Suretouch Reflections Counter Mounted Soap Dispenser KCC91934

![Gojo Ltx12 Clear Mild Foam Handwash Refill - 40.6 Fl Oz [1200 Ml] - (191102ct)](/_content/items/images/20/3914120/001.jpg)

Gojo Ltx12 Clear Mild Foam Handwash Refill - 40.6 Fl Oz [1200 Ml] - (191102ct)

Pressure Washer Quick Connect M22 X 1/4" Quick Connect Plug- Karcher Style

3/8" Pressure Washer Thermal Relief Valve 100557 General Pump Thermal Valve

Microburst Duet Automatic Odor Control Dispenser

Urinal Screen, Para with Deodorizer Block, Cherry scent, 1 dozen/box

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies