US $19,000.00

| Condition | Used

:

An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “Used, guaranteed to be in good working condition.” |

Directions

Similar products from Tools for Mail Shipments

New OTI kit, Replaces O Ring Advancing Gate,Silver Series Hard. Set of 12.

New OTI part, Replaces Streamfeeder 6" Adj Transport 1-1/2" Discharge Belt

New OTI part, Replaces Streamfeeder #44841034 Timing Belt 206xL037 3/8 .200 Ptch

New OTI part, Replaces Streamfeeder #43500096 Timing Belt 170xL037 3/8 .200 Ptch

New OTI part, Replaces Streamfeeder #51050010 Timing Belt 86XL037 3/8 .200 Pitch

New OTI Part, Replaces Streamfeeder #335600097 Timing Belt 160xL037 3/8 .200

Sure Feed Friction Feeder Grooved Elevator Belt

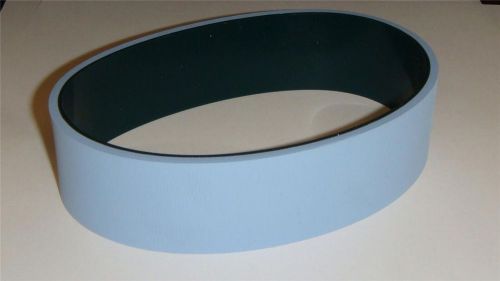

Sure Feed Friction Feeder Smooth Elevator Belt

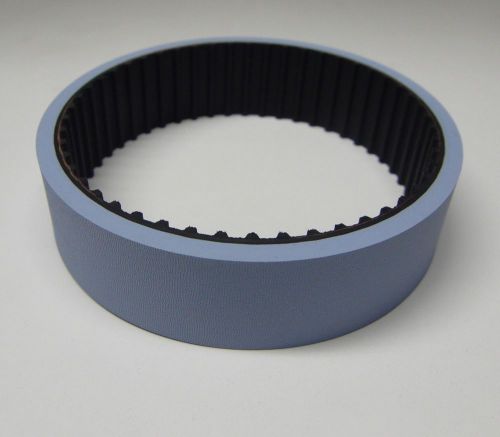

Sure Feed Friction Feeder Main Feed Gum Belt Light Blue

Used Bell & Howell Trim Winder

PITNEY BOWES E575 Envelope Feeder Doesn't Power On Parts & Repair

Automecha ACCUFAST 2 Labeller Labeler

Neopost Hasler Formax Postalia Folder Inserter Tune Up Kit

New OTI part, Replaces Streamfeeder #51745035 V-1000 Gum Feed Belt

Sure-Feed Belt Kit for SE1200IJ ECO Series Feeder, Grooved Belt

Sure-Feed Belt Kit for SE1200IJ ECO Series Feeder, Smooth Belt

Sure-Feed Belt Kit for SE1200IJ and 1800IJ Feeder, Grooved, Separator Belts

Sure-Feed Belt Kit for SE1200IJ and 1800IJ Feeder, Grooved, Separator O-Rings

Sure-Feed Belt Kit for SE1200IJ and 1800IJ Feeder, Smooth, Separator Belts

Sure-Feed Belt Kit for SE1200IJ and 1800IJ Feeder, Smooth, Separator O-Rings

People who viewed this item also vieved

4 x Mimaki JV5 JV33 Epson DX5 Solvent Water InkJet Damper

4pcs Mimaki Damper JV5 JV33 Epson DX5 Printhead Solvent Water InkJet

SCREEN PTR CTP platesetter Tail Clamps set

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies